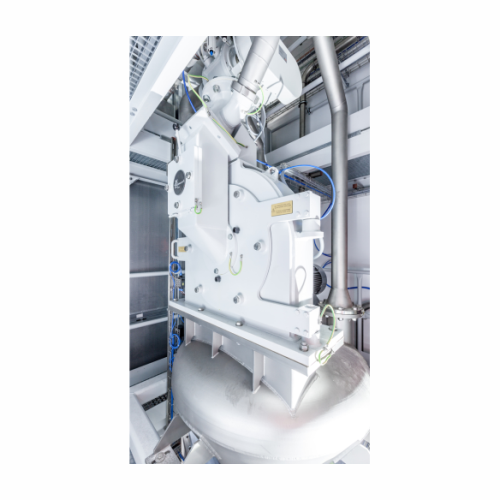

Industrial sugar grinding mill

Optimize sugar fineness with a compact grinding solution, ensuring high-speed operation and low maintenance without compromising quality in confectionery and sugar processing.

Grinds Sugar into Consistent Icing Powder

The Bauermeister UCOM Sugar Grinding Mills are engineered for precision and efficiency in food processing. These mills feature explosion-resistant construction compliant with Atex 2014/34/EU regulations, ensuring safety in sugar processing facilities. They are specifically designed to produce icing sugar with fineness up to 90% <100 µm for versatile applications including chocolate bars and malt products. Equipped with temperature-monitored bearings and dust-tight housing, these mills minimize maintenance costs while supporting continuous, high-speed operations. The compact design and efficient energy use make these mills ideal for integration into existing production lines, particularly for confectionery manufacturers and sugar processing companies. With capacities ranging from 400 to 4,000 kg/h, the UCOM series delivers customized solutions to meet specific throughput requirements, all while maintaining energy savings via optimized motor control.

Benefits

- Ensures uniform product quality with precision sugar grinding capabilities.

- Lowers operational costs through compact design and efficient energy use.

- Enhances safety standards with explosion-proof construction.

- Supports seamless production line integration with various throughput capacities.

- Minimizes maintenance with durable, dust-tight construction and temperature-monitored bearings.

- Applications

- Cocoa, Grains, Sugar, Malt, Nuts, Seeds, Chocolate

- End products

- Icing sugar, Cocoa powder, Roasted almonds, Malt extract, Cocoa nibs, Chocolate bars, Tahini

- Steps before

- Crystal Sugar Feeding, Pre-Treating

- Steps after

- Commercial Icing Sugar Packaging

- Input ingredients

- crystal sugar

- Output ingredients

- commercial icing sugar, <100 µm, <200 µm, icing sugar distribution percentages

- Market info

- Hamburg Dresdner Maschinenfabriken GmbH is known for expertise in manufacturing industrial machines for the cocoa, chocolate, and confectionery industries, particularly focusing on roasting, grinding, and refining processes. They have a strong reputation for quality and innovation.

- Capacity

- 400–4000 kg/h

- Explosion resistance

- 10 bar

- Grinding fineness

- 90%, lt

- 100 µm / 200 µm

- Design

- Compact, welded

- Maintenance cost

- Low

- Operation cost

- Low

- Monitoring

- Temperature monitored bearings

- Dust protection

- Dust tight

- ATEX conformity

- 2014/34/EU

- Batch vs. continuous operation

- Batch / Inline Continuous

- Explosion Resistance

- 10 bar explosion shock resistant

- Automation level

- Manual / PLC / SCADA

- Temperature Monitoring

- Temperature monitored bearings

- Compact Design

- Extremely compact design

- Dust Tightness

- Dust tight

- Flow Type

- Sugar Grinding

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Sugar type

- Crystal Sugar

- ATEX certification

- 10 bar explosion shock resistant conforming Atex 2014/34/EU regulations

- Compact footprint

- Extremely compact design

- Machine design

- Welded design

- Discharge method

- Dust tight

- Compact footprint

- Yes

- Control panel type

- PLC-controlled