Making Cocoa Nibs

Find innovative production technology for making cocoa nibs and connect directly with world-leading specialists

Known as part of the chocolate-making process, cocoa nibs come from the beans derived from the Theobroma cocoa tree. They are nothing else but cocoa beans that have been dried, fermented, and then cracked and separated from their husk.

Technology picks for cocoa nibs

Cocoa nibs and malt roaster

Achieve precise roasting, sterilization, and taste control of cocoa and malt with adaptable heat...

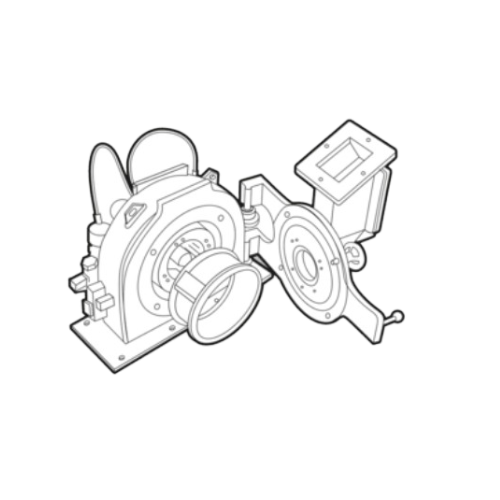

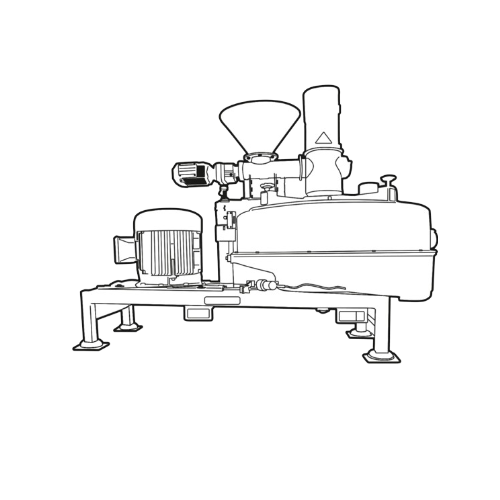

Cocoa nibs pre-grinder for high fat seeds and nuts

Enhance your processing line with high-speed pre-grinding designed to ...

Cocoa nibs roaster with sterilization control

Achieve precise roasting and sterilization of cocoa nibs and malt with real-...

Industrial cocoa nib grinder for bean to bar production

Streamline your chocolate production with this versatile grinder,...

Tell us about your production challenge

From beans to nibs – Harvesting, drying and fermentation…

After harvesting, cocoa beans are not as sweet as chocolate, so to allow them to develop the chocolatey flavor we all love, they are gently mixed and left to rest for a few days (fermentation period). Fermentation can last up to 7 days in which the white pulp surrounding the cocoa beans is turned into alcohol by the yeasts in the air. Drying reduces the high level of moisture cocoa beans have after fermentation.

…roasting and winnowing

During roasting, cocoa beans break down and their shell becomes brittle so it can be easily removed (winnowing). Since the nibs are heavier than the husk, winnowing is usually done by blowing air through the beans to get rid of the shell. Nearly 30% of the weight of the cocoa beans is actually lost in the winnowing process. This step is crucial because if there is any shell residue left, it can give an unwanted flavor to the chocolate product.

Cocoa nibs making equipment - From bean to bar

Whether it’s compound chocolate, chocolate bonbons, or chocolate bars, in a bean-to-bar process you start the chocolate-making process from scratch. First, you need to roast and dry your beans. Pay attention to the roasting process; it’s when you roast that the flavors of the chocolate develop. After cracking and winnowing the cocoa beans, you need to refine cocoa nibs to turn them into chocolate.

Processing steps involved in cocoa nibs making

Which cocoa nibs technology do you need?

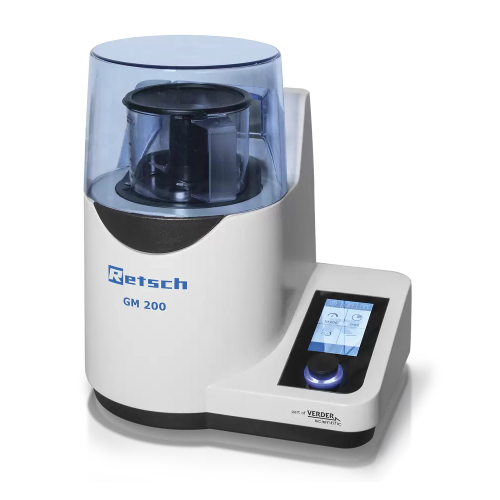

Mortar grinder for reproducible sample preparation

Achieve precise and consistent material preparation with this mortar g...

Knife mill for food and feed sample grinding and homogenization

Achieve consistent texture and precise size reduction of...

Precision chocolate production from cocoa nibs

Achieve ultra-fine chocolate textures by utilizing stone conching to bring ...

Batch tempering solution for chocolate production

Achieve precise temperature control for chocolate consistency and quali...

Artisan line for fine chocolate mass production

Transform raw cocoa beans into exquisite chocolate through precise control...

Air classifier for fine powder processing

Enhance your production line with precise particle size control and energy-effic...

Conical screw cooker for food production

Optimize batch and continuous operations in your production line with efficient mi...

Cocoa sterilizing and alkalizing plant

Optimize cocoa product quality with a system engineered for precise sterilizing, alk...

Inline cocoa bean roaster

Streamline your cocoa production by achieving consistent roast quality with precision heat control...

Industrial sugar grinding mill

Optimize sugar fineness with a compact grinding solution, ensuring high-speed operation and l...

Chocolate refiner and conche solution

Elevate your chocolate production with a versatile solution that seamlessly integrate...

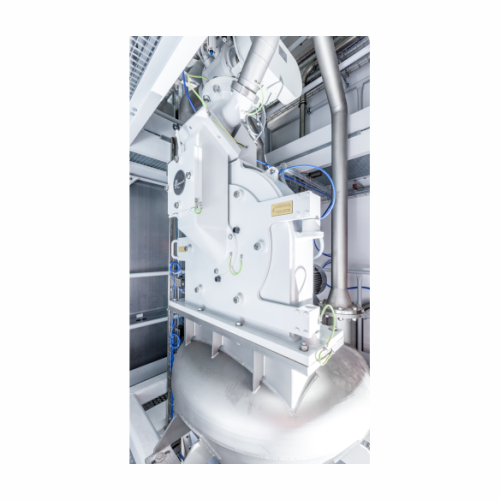

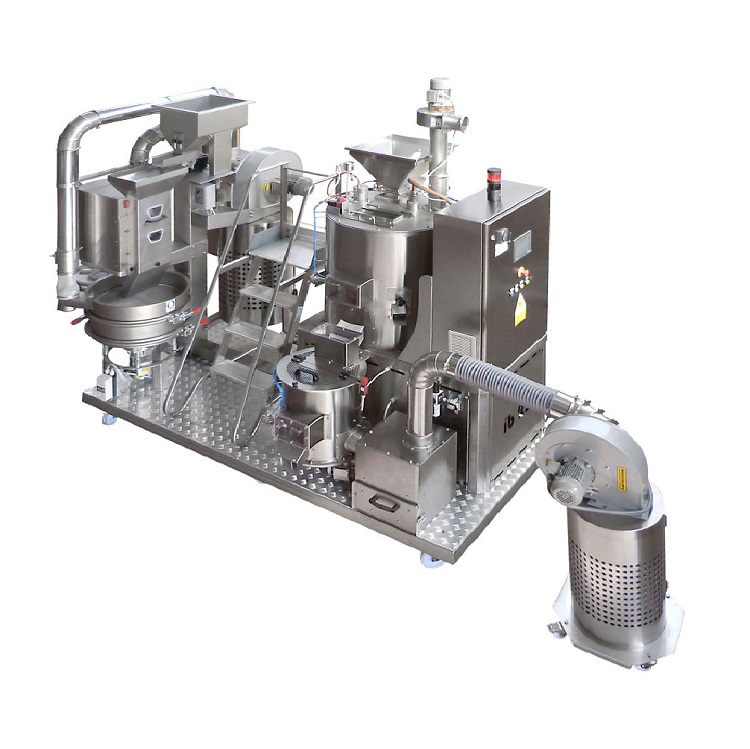

Cocoa nib grinding system

Optimize your cocoa and nut processing with precision grinding to achieve a pumpable mass, ensurin...

Cocoa nibs pre-grinder for high fat seeds and nuts

Enhance your processing line with high-speed pre-grinding designed to ...

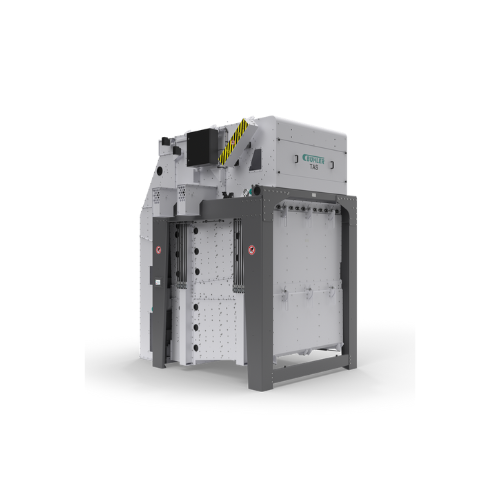

Grain cleaning system for high-quality processing

Optimize your grain processing with a versatile cleaning system designe...

Optical sorter for grains, seeds, and plastics

Enhance sorting efficiency with cutting-edge optical technology that distin...

Single-shaft conche for chocolate production

Optimize your chocolate production with a conche that delivers shorter conchi...

Industrial grain flaking mill

For efficient grain processing, achieve uniform flake quality with advanced temperature-contro...

Debacterizing system for cocoa beans

Ensure your cocoa processing meets stringent hygiene standards with this advanced deba...

Infrared pre-treatment system for cocoa beans

Unlock maximum yield and preserve flavor in cocoa processing with this innov...

Infrared pre-treatment for cocoa beans

Achieve optimal cocoa nib separation and consistent moisture control while preventin...

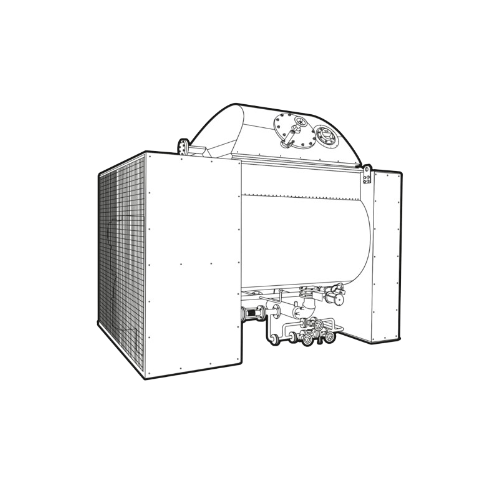

Cocoa nibs and malt roaster

Achieve precise roasting, sterilization, and taste control of cocoa and malt with adaptable heat...

Cocoa nibs and malt roasting system

Enhance your flavor profile with precise roasting, sterilization, and taste control cap...

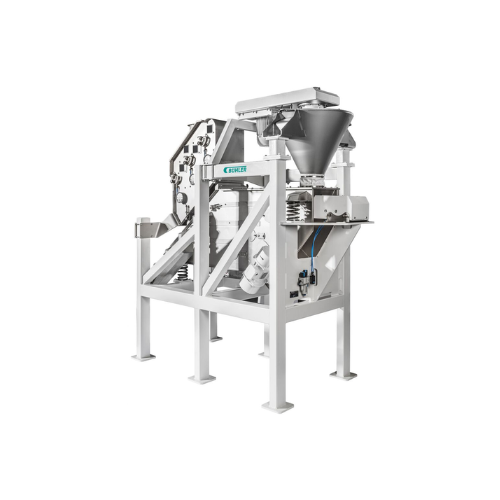

Winnowing system for cocoa processing

Achieve precise cocoa separation with a high-efficiency winnowing system designed for...

Laboratory winnowing system for cocoa beans

Efficiently crush cocoa beans and separate shells from nibs with precision and...

Cocoa nibs roaster with sterilization control

Achieve precise roasting and sterilization of cocoa nibs and malt with real-...

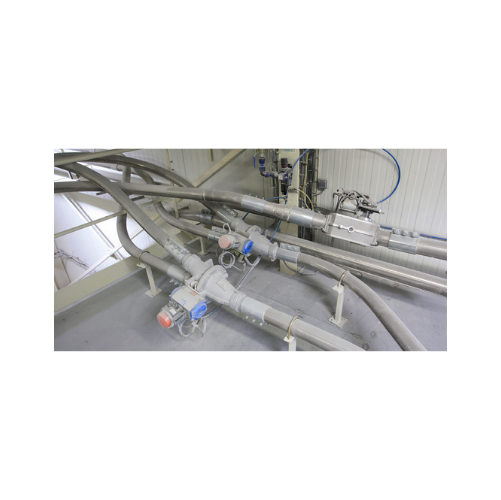

Flap diverter valves for pneumatic conveying

Streamline material flow in your pneumatic conveying system by effortlessly r...

Cocoa bean peeling solution

Enhance your cocoa and coffee production with efficient peeling, reducing waste and ensuring hig...

Cocoa bean processing line from cocoa pod to cocoa nibs

Streamline your cocoa production process by transforming raw coco...

Cocoa bean winnower

Transform roasted cocoa beans into nibs efficiently, ensuring precise separation of cocoa from its shell,...

Industrial cocoa nib grinder for bean to bar production

Streamline your chocolate production with this versatile grinder,...

Bean to bar chocolate production equipment

Transform cocoa beans into exquisite single-origin chocolate with complete cont...

Entry level cocoa roaster

The biggest challenge that small-scale cocoa processing manufacturers face is even and thorough ro...

Small capacity cocoa grinder

The first step of producing almost any kind of chocolate starts with grinding cocoa beans to ge...

Entry level bean to bar line

One of the challenges when setting up a small-scale cocoa processing factory is making all of t...

Small scale cocoa winnower

In the small-scale production of cocoa-based products, one of the challenges that manufacturers f...

Continuous cocoa bean roasting line

When you are processing chocolate, after the conditioning and fermenting of cocoa, the ...

High-Speed Pouch Packaging Machine

For large scale production of powders and liquids in a wide range of industry sectors, a...

Small scale cocoa beans processing machine

For the highest quality chocolate production, complete control of the entire pr...

Entry level bean-to-bar machine

The production of high-quality chocolate from the bean can often be out of the reach of smal...

R&D roaster for cocoa beans

When designing a new chocolate line or experimenting with new ingredients for existing processes...

Five deck cocoa bean winnower

Skin and shell removal from cocoa beans is necessary to produce great tasting chocolate. Compl...

Ball roaster for cocoa beans

Homogeneous roasting of cocoa beans is essential for the production of fine chocolate. Precise ...