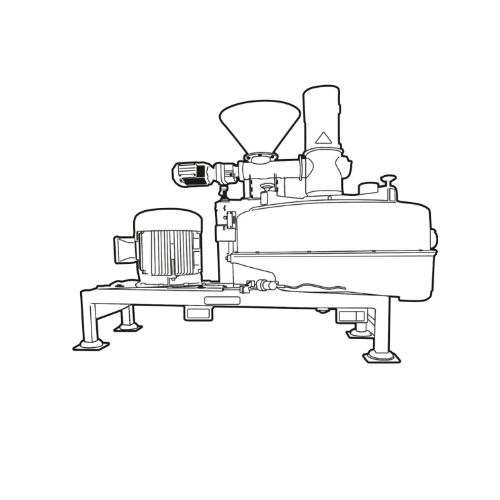

Cocoa nib grinding system

Optimize your cocoa and nut processing with precision grinding to achieve a pumpable mass, ensuring consistent texture and enhanced flow properties in your confectionery formulations.

Grinds High-Fat Cocoa and Nuts Efficiently

The Bauermeister Beater Blade Mill SMM is engineered for high-speed grinding of high-fat content products like cocoa nibs and hazelnuts. Its unique beater blades break down material to precise particle sizes, ensuring a pumpable mass ideal for cocoa liquor, chocolate paste, and nut butter. With a jacketed grinding chamber, maintain consistent temperatures for optimal flow properties while achieving particle sizes between 0.15 and 0.5 mm. The equipment operates continuously, with non-ground particles retained within the system, minimizing wear on downstream refiners. Easily integrate into existing production lines with quick blade and sieve changes, supported by automatic grease lubrication. Ideal for chocolate manufacturers and confectionery producers, this mill supports high-capacity processing while maintaining consistent fineness and quality. Choose stainless steel options for processing durability, and benefit from minimal maintenance due to reversible rotation and easy cleaning procedures.

Benefits

- Enhances product consistency with precise particle size control.

- Minimizes maintenance time with quick blade and sieve changes.

- Preserves product quality by maintaining controlled processing temperatures.

- Reduces operational wear on downstream equipment with continuous particle retention.

- Increases processing efficiency with high-capacity throughput.

- Applications

- Cocoa, Snacks, Hazelnuts, Nuts, Sweets, Chocolate

- End products

- Chocolate paste, Confectionery fillings, Cocoa liquor, Hazelnut paste, Nut butter

- Steps before

- Pre-Treating, Winnowing, Roasting

- Steps after

- Fine Grinding, Pressing, Chocolate Making

- Input ingredients

- cocoa nibs, hazelnuts

- Output ingredients

- pumpable mass, finely ground product, reduced moisture content

- Market info

- Hamburg Dresdner Maschinenfabriken GmbH is known for expertise in manufacturing industrial machines for the cocoa, chocolate, and confectionery industries, particularly focusing on roasting, grinding, and refining processes. They have a strong reputation for quality and innovation.

- Capacity

- High, Constantly Maintained

- Fineness

- Controlled by Mesh Size (0.15 – 0.5 mm)

- Grinding Chamber Diameter

- 802 mm / 1140 mm

- Grinding Chamber Height

- 333 mm / 460 mm

- Connected Load

- 45, 90, 110

- Number of Beater Blades

- 8

- Temperature Control

- Jacketed Chamber with Hot/Cold Water Circulation

- Speed

- High Speed Rotating Blades

- Automation

- Automatically Operated Grease Lubrication

- Working mechanism

- Beater blade milling

- Integrated steps

- Pre-, fine grinding

- Batch vs. continuous operation

- Continuous

- Temperature control

- Jacketed design for controlled temperature

- Cleaning method

- Cleaning without removal of sieves

- Changeover time

- Fast exchange of blades and sieves

- Automation level

- Automatic grease lubrication

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Diameter of Grinding Chamber

- 802 mm / 1140 mm

- Height of Grinding Chamber

- 333 mm / 460 mm

- Number of Beater Blades

- 8

- Discharge method

- Annular sieve with mesh size 0.15 – 0.5 mm

- Customization of mesh size

- 0.15 – 0.5 mm

- Blades and sieves exchange

- Fast exchange

- Temperature control

- Jacketed chamber for temperature control