Cocoa sterilizing and alkalizing plant

Optimize cocoa product quality with a system engineered for precise sterilizing, alkalizing, and mixing processes, ensuring enhanced texture and flavor profiles in your chocolate and cocoa-based goods.

Sterilizes and Alkalizes Cocoa Products

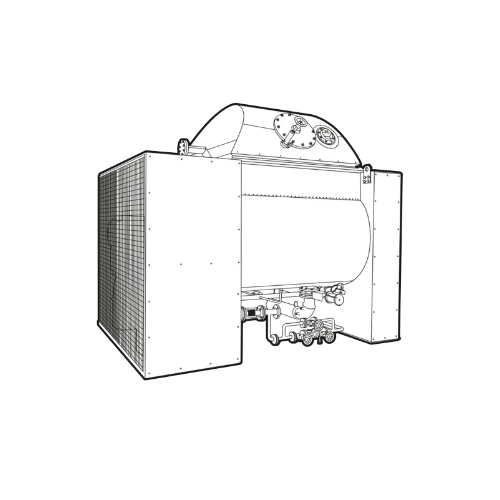

The Cocoa Sterilizing and Alkalizing Plant HBM V from Hamburg Dresdner Maschinenfabriken is an integrated solution designed for cocoa processors and chocolate manufacturers. This versatile equipment features a vacuum mixer system for effective sterilization and alkalization of cocoa liquor, cake, and nibs, enhancing product quality and hygiene. Available in customizable one- and two-shaft versions, it utilizes a fully jacketed mixer trough heated with steam or water up to 160°C. Capable of handling batch volumes between 500 to 6000 liters, it offers precise dosing facilitated by load cells and diverse mixing blades suited to various applications. Its closed, hygienic design is constructed from mild or stainless steel, powered by robust gear motors ranging from 22 to 120 kW. The PLC-controlled system enables seamless integration with existing setups and features a touch panel for easy process management, including recipe-based treatment programs customizable to specific customer requirements. With options for variable material constructions and advanced vacuum systems, it ensures efficient operation with quick product drying and sample taking capabilities.

Benefits

- Enhances product quality with precise sterilizing and alkalizing processes.

- Reduces processing time and energy costs with efficient heating and vacuum systems.

- Increases production flexibility with customizable batch volumes and mixing configurations.

- Ensures seamless integration and operational efficiency in existing production lines.

- Maintains high hygiene standards with easy-to-clean, closed-system design.

- Applications

- Cocoa products, Cocoa liquor, Cocoa cake, Cocoa nibs, Chocolate

- End products

- Cocoa butter, Cocoa powder, Milk chocolate, White chocolate, Chocolate bars, Baking cocoa, Dark chocolate, Chocolate chips, Cocoa mass, Alkalized cocoa powder

- Steps before

- Cleaning, Pre-Treating, Winnowing

- Steps after

- Roasting, Grinding, Pressing

- Input ingredients

- cocoa liquor, cocoa cake, cocoa nibs

- Output ingredients

- sterilized cocoa liquor, alkalized cocoa liquor, alkalized cocoa cake, alkalized cocoa nibs

- Market info

- Hamburg Dresdner Maschinenfabriken GmbH is known for expertise in manufacturing industrial machines for the cocoa, chocolate, and confectionery industries, particularly focusing on roasting, grinding, and refining processes. They have a strong reputation for quality and innovation.

- Batch Volumes

- 500 to 6000 Litre

- Heating Method

- Steam, Water, or Other Medias up to 160°C / 3 bar

- Mixing Blades

- Various Assortment for Different Applications

- Load Control

- Load Cells for Dosing of Components

- Material Construction

- Mild or Stainless Steel

- Motor Power

- 22 to 120 kW

- Control System

- PLC with Touch Panel

- Vacuum System

- Suitable Systems for All Sizes

- Discharge System

- Special Feed and Discharge Systems

- Sample Taking

- Sample Taking Valve

- Batch vs. continuous operation

- Batch

- Automation level

- PLC

- Cleaning method

- Closed design for hygiene standards

- Energy efficiency

- Robust helical-bevel gear motors

- Batch size

- 500 - 6000 Litres

- Temperature control

- Up to 160°C

- Sample taking valve

- Yes

- Corrosion resistance

- Stainless steel

- Cleanability

- Easy to clean design

- Abrasion resistance

- Mild steel options

- Biological compatibility

- Suitable for food processing

- Batch volume

- 500 to 6000 Litre

- Material construction

- Mild or stainless steel

- Heating method

- Steam, water or other medias up to 160°C / 3 bar

- Mixing blades

- Various assortment

- Drive motor power

- 22 to 120 kW

- Load control

- Load cells for component dosing

- Vacuum system

- Suitable for all sizes

- Design

- Closed with even contours

- Control interface

- Touch panel with menu navigation

- Sample taking valve

- Available

- Control panel type

- Touch screen operator panel

- Integration possibilities

- Stand Alone unit or integration in existing lines

- Batch size customization

- 500 to 6000 Litre Batch Volumes

- Material construction type

- Mild or stainless steel

- Mixing blade assortment

- Various mixing blades for different applications

- Heating medium

- Steam, water, or other medias up to 160°C

- Vacuum system suitability

- Suitable for all sizes