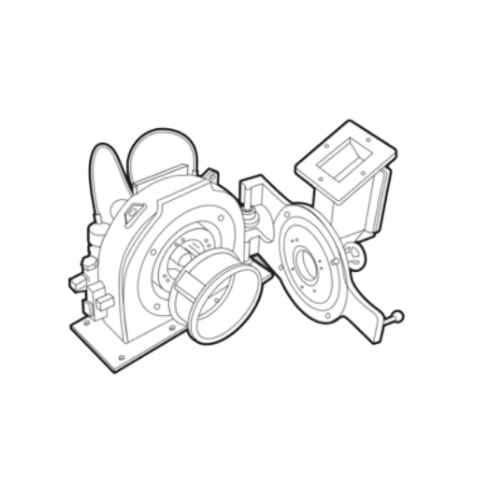

Inline cocoa bean roaster

Streamline your cocoa production by achieving consistent roast quality with precision heat control, maximizing flavor profile while ensuring uniform results in every batch.

Roasts Cocoa Beans Continuously and Evenly

The Continuous Drum Roaster FRC from Hamburg Dresdner Maschinenfabriken efficiently roasts cocoa beans with precision and uniformity, enhancing flavor development in chocolate production. Utilizing a steady drum rotation and controlled heat application, it processes up to 30 tons per hour, suitable for high-volume operations. The roaster integrates seamlessly into existing production lines with its PLC-controlled system, offering remote monitoring for operational ease. Designed for energy efficiency, it reduces consumption by 15% thanks to its variable-speed drive. Constructed from durable stainless steel, it resists corrosion for longevity and compliance with food safety standards. Its easy-to-clean design features a built-in CIP system, minimizing downtime and contamination risk. Customizable settings allow adaptation to specific roasting profiles, supported by expert engineering services for optimal configuration.

Benefits

- Enhances cocoa flavor development with precise and uniform roasting.

- Increases production efficiency with high-capacity processing up to 30 tons per hour.

- Minimizes energy costs with a 15% reduction in power consumption.

- Simplifies maintenance and cleaning with an integrated CIP system.

- Customizable settings ensure optimal roasting profiles to meet specific production needs.

- Applications

- Grains, Oilseeds, Malt, Nuts, Cocoa processing, Seeds, Chocolate making

- End products

- Cocoa butter, Chocolate couverture, Cocoa powder, Baking chocolate, Milk chocolate, White chocolate, Roasted nuts, Nut butter, Cocoa liquor, Malted beverages, Malt extract, Cocoa nibs, Chocolate bars, Dark chocolate, Chocolate chips, Tahini, Nut pastes, Malted milk products

- Steps before

- Cleaning, Pre-Treating, Winnowing

- Steps after

- Pressing, Conching, Packing

- Input ingredients

- cocoa beans, grains, seeds, malt, nuts, oilseeds, sugar

- Output ingredients

- cocoa nibs, cocoa liquor, pressed cocoa, chocolate, ground cocoa, ground grains, ground seeds, roasted nuts, tahini, cocoa powder

- Market info

- Hamburg Dresdner Maschinenfabriken GmbH is known for expertise in manufacturing industrial machines for the cocoa, chocolate, and confectionery industries, particularly focusing on roasting, grinding, and refining processes. They have a strong reputation for quality and innovation.

- Roasting Type

- Batch / Continuous

- Grinding Type

- Pre-, Fine Grinding

- Mixing System

- Double Shaft Batch Mixers

- Conching Type

- Vertical Single-Shaft / Double-Shaft Batch Conches

- Alkalizing Process

- Alkalising Plant FNA

- Pressing Type

- Cocoa Pressing Plant HHP

- Sugar Grinding System

- Bauermeister Sugar Mills

- Roaster Series

- M350 / G Series

- Grinding Type

- Beater Blade Mill SMM / Spindle Mill HKM

- Bean to Chocolate Line

- Drum Roaster G Series / MacIntyre Refiner

- Refining Type

- Five-Roll Refiners

- Pre-Refining System

- Pre-Refiners HVS

- Batch vs. continuous operation

- Batch / Inline Continuous

- Automation level

- Manual / PLC / SCADA

- CIP/SIP

- CIP 121°C / SIP 135°C

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Cleaning method

- CIP / Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Roaster type

- Batch / Continuous / Drum

- Mill type

- Spindle / Beater Blade

- Conche type

- Continuous / Vertical Single-Shaft / Double-Shaft Batch

- Mixing type

- Double Shaft Batch Mixers

- Control panel type

- Touchscreen / Buttons

- Integration possibilities

- SCADA / PLC / ERP

- Discharge method

- Screw conveyor / Pneumatic

- Compact footprint

- Modular design