Making Bonbons

Find innovative production technology for making chocolate bonbons and connect directly with world-leading specialists

Bonbons are chocolate confectioneries originating from the French royal court in the 17th century. From the French word bon meaning “good”, bonbons are chocolate candies with a filling inside, usually fruits, brittle, nougat, or caramel. Equipment for chocolate bonbons are varied and must be capable of chocolate tempering, molding, scraping, filling, and covering.

Technology picks for chocolate bonbons

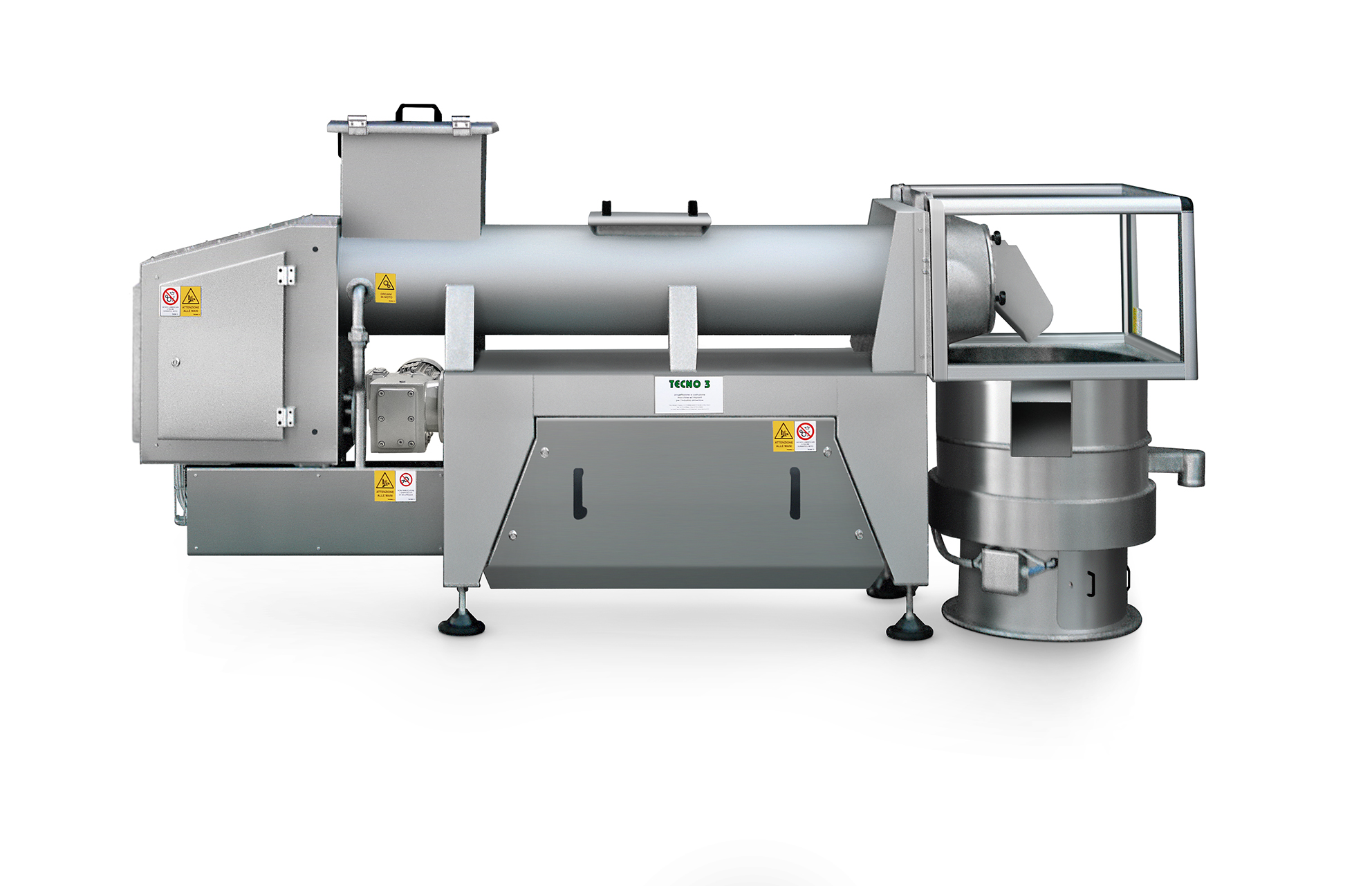

Industrial melter for chocolate rework

Wastage or out-of-specification products are not uncommon in the chocolate manufactu...

Entry level bean to bar line

One of the challenges when setting up a small-scale cocoa processing factory is making all of t...

Multi-nozzle chocolate decorator

Make zigzag, corner, or loop designs on your enrobed products.

Hollow chocolate figure spinning solution

Achieve uniform chocolate coating in hollow figurines with precision spinning te...

Tell us about your production challenge

Tempering and refining your chocolate bonbons

Tempering involves heating and cooling your chocolate so the fats (cocoa butter) can crystallize uniformly. The objective of tempering is the formation of Form 5 crystals which develop at 93° to 95° F.

Tempering and refining your chocolate using a tempering machine facilitates the formation of chocolate crystals necessary to get that gloss, snap, and crunchy texture of your chocolate bonbons. If you simply melt your chocolate and then cool it down, you cannot give the bonbon shells the glossy, shiny look we love.

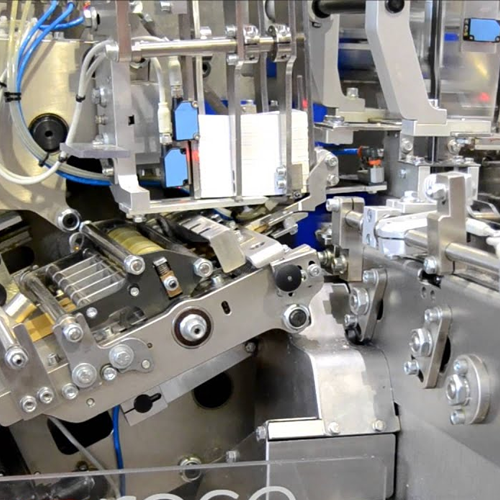

Essential equipment for chocolate bonbon making

After a filling machine fills the molds with tempered chocolate to form the shell, the excess chocolate is scraped off. Be vigilant in checking that molds are totally clean and dry to ensure that the chocolate does not come in contact with moisture. Moisture can cause chocolate blooming, reduce surface luster and chocolate snappiness. To get rid of any air bubbles, the molds on a conveyor belt must be vibrated. In this way, the bonbon shells can develop properly.

After hardening, you can fill the shell with your favorite ingredients like fruit, caramels and ganache. You can then proceed to covering the chocolate bonbons with another layer and subjecting them to cooling. This allows the Type V crystals to fully settle and crystallize, resulting in that luster and snap you are looking for in your chocolates.

Chocolate maker vs. chocolatier: how are bonbons involved in these?

As a producer, what should you identify yourself to be? In terms of bonbon making, are you the chocolate maker or the chocolatier?

Chocolate makers, as their name implies, make chocolate bars. From the processing of the beans, chocolate makers follow every step of the chocolate making process until tempering to form the chocolate bars. On the other hand, chocolatiers, also known as chocolate melters, receive the chocolate bars and melt them to create whatever product they desire. They do not make the chocolate from scratch but are able to produce chocolate products.

You may have also heard of bean to bonbon. This refers to chocolatiers who receive beans, produce chocolates, and use these to develop products, such as bonbons. These producers do not necessarily grow their own beans, but do participate in every step of the chocolate making process. The bean to bar market is well-perceived by consumers, projecting to reach 24.54 billion USD by 2027.

Molding vs. enrobing: which is which?

Depending on the design of your bonbon and its filling, you can choose molding or enrobing as your chocolate capsulation method.

Molding requires you to have the chocolate shell formed first before putting the filling in and closing the shell. Liquid chocolate is poured over your molds, allowed to settle, then filled with your flavoring of choice, covered, and cooled. This is best when you want to create specific designs, shapes, and other decorations. However, this can be time-intensive and requires strict moisture controls.

Enrobing entails that you form your core first before wrapping this in chocolate. After forming the core, liquid chocolate is poured over it. If a liquid core is used, this must be covered first in a chocolate shell or something similar prior to enrobing. Compared to molding, this is a faster process and can be upscaled, allowing you to make many products rapidly.

Processing steps involved in chocolate bonbons making

Which chocolate bonbons technology do you need?

Chocolate tempering quality analyzer

Ensure your chocolate’s tempering precision with a device that accurately assess...

Tailor-made transport systems for confectionery production

Optimize your confectionery production line with customizable...

Chocolate decoration system for pralines and biscuits

Achieve intricate chocolate patterns and uniform coatings on confec...

Coating solution for nuts and dried fruits

Easily apply multiple layers of chocolate to nuts, coffee beans, and more, achi...

Compact chocolate tempering solution

Enhance your chocolate products’ finish and efficiency: this compact solution en...

Chocolate moulding system for small batch production

Streamline your chocolate product line with precision moulding and t...

Cooling tunnel for artisanal biscuits and chocolates

Streamline your confectionery production with a cooling solution des...

Electric melting tray for small-scale chocolate applications

Effortlessly melt and prepare chocolate with precision and ...

Mini praline dosing system

Achieve precise dosing and versatile moulding for mini pralines and chocolate creations, streamli...

Compact chocolate moulding system

Optimize your chocolate creations with a compact system designed for easy melting, temper...

Compact chocolate moulding solution 3-in-1

Streamline your confectionery creations with a versatile 3-in-1 machine that se...

Chocolate moulding line for center-filled chocolates

Streamline your chocolate production with a versatile moulding line ...

Chocolate one-shot moulding line

Streamline your chocolate production with a high-speed moulding line designed to simultaneo...

Automatic chocolate feeding conveyor

Efficiently connect your chocolate production to wrapping stages with this high-speed ...

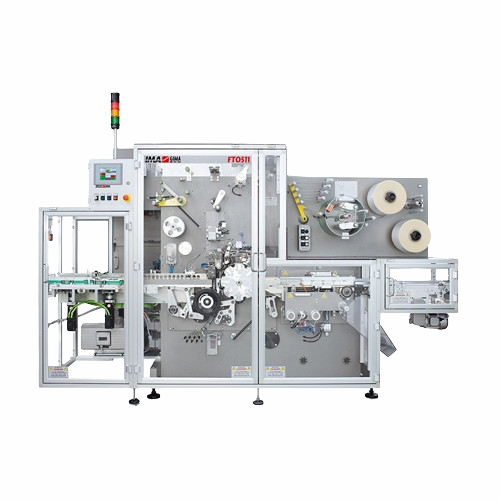

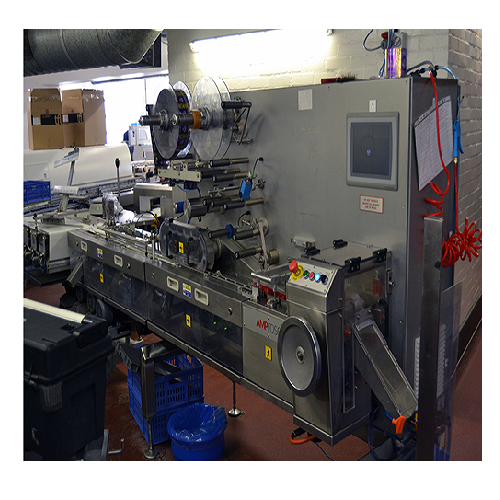

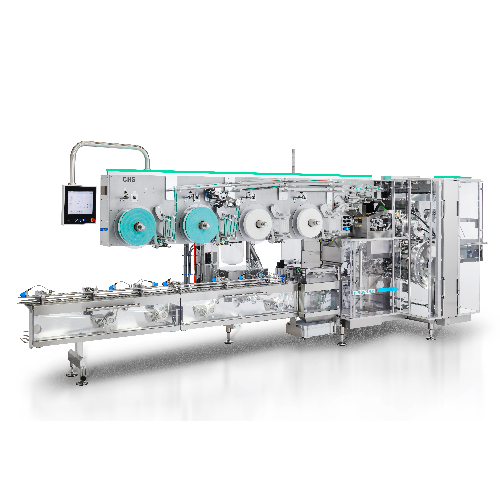

Chocolate wrapping machine for confectionery production

Achieve precision and elegance in packaging with high-speed wrapp...

Industrial chocolate ball mill for uniform grinding

Achieve precise chocolate particle refinement with this robust ball m...

Inline chocolate filter for large particle removal

Ensure the purity and consistency of your chocolate products by effici...

Laboratory refiner/conche for chocolate processing

For chocolate producers seeking precise control over texture and flavo...

Chocolate refiner/conche system

Streamline your chocolate production with a versatile solution that combines grinding, mixin...

High-speed overwrapping for display boxes

Achieve seamless overwrapping of display boxes with ultra-high-speed capabilitie...

Vertical cartoning system for confectionery products

When you need high-speed, versatile cartoning capabilities for varie...

Monoblock loading unit for confectionery packaging

Optimize your confectionery production line with a compact unit that i...

Wrap-around case packer for coated sweets

Effortlessly enhance product presentation and shelf-readiness by securely packin...

Vision guided multi-robot system for flowpack candy packaging

Streamline your confectionery packaging process with high-...

Flow wrapping for bulk confectionery products

Efficiently orient, feed, and wrap bulk confectionery items with seamless in...

X-ray inspection system for contaminant detection

Detect and eliminate foreign contaminants in a wide range of food produ...

X-ray inspection system for identifying foreign bodies in food products

Ensure precise detection of foreign materials i...

Stainless steel chocolate tank for storage and processing

Efficiently control temperature and consistency for chocolate ...

Waxing station for confectionery products

Optimize your product’s final presentation and quality by applying a preci...

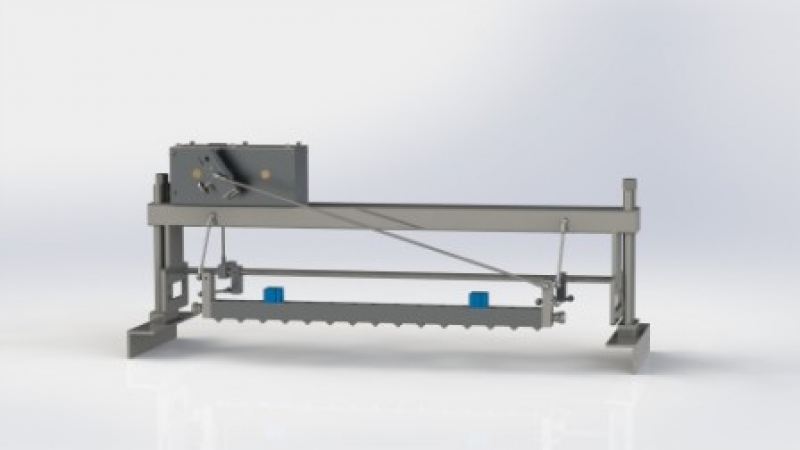

Confectionery cutting system for accurate results

Achieve precision and flexibility in modern confectionery production wi...

Chocolate mould washer

Ensure immaculate cleanliness and precise drying of chocolate moulds, enhancing production efficiency ...

Thin chocolate shell forming

Create gourmet confections with precision by forming delicate chocolate shells, perfect for ver...

Laboratory batch chocolate processing unit

Achieve precision in developing chocolate recipes with a compact 3-in-1 unit th...

Double-overthrow conche for chocolate production

Achieve precise taste and texture in chocolate production with reduced en...

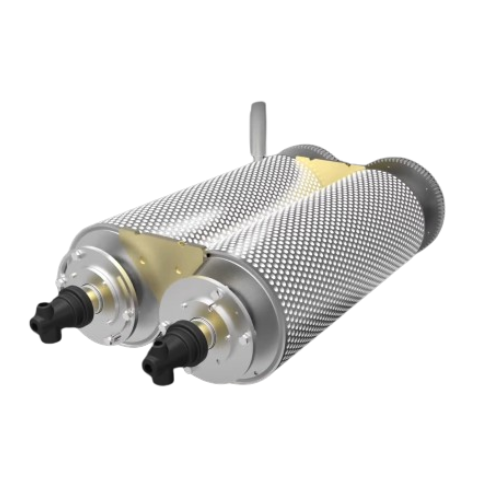

Five-roll refiner for chocolate production

Achieve precise particle size control and energy efficiency in your chocolate r...

Chocolate chip depositor for small scale production

Achieve precise chocolate chip production with consistent size and we...

Wrapper for flat bottomed chocolate articles

Optimize your confectionery packaging with a machine designed for swift, secu...

Neapolitan chocolate wrapping solution

Efficiently wrap and label square chocolates with this fold wrap solution, ideal for...

Multi-style candy and chocolate wrapper

Achieve high-speed, precision wrapping for diverse confectionery products with vers...

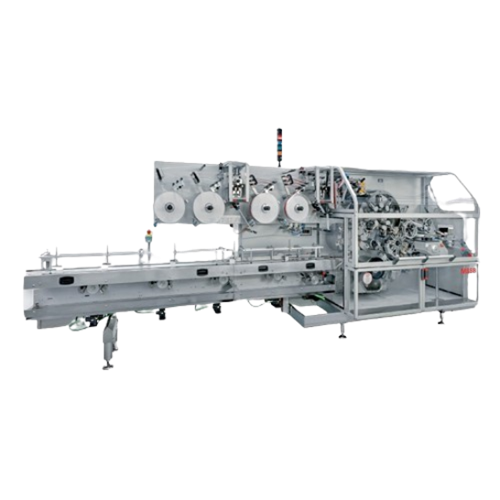

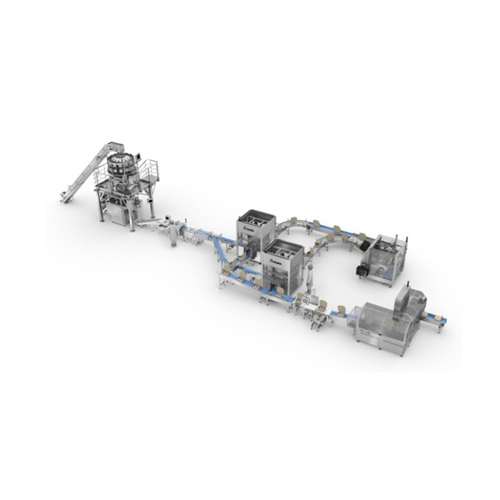

Chocolate production belt line

Optimize your chocolate and bakery production with a versatile belt line designed for continu...

Chocolate moulding line for lentils, balls, and eggs

Achieve precision and efficiency in molding chocolate centers for le...

Flexible chocolate moulding line for limited space production

Optimize your production line with a versatile moulding sy...

High capacity chocolate moulding line

Maximize your production capacity with a tailor-made moulding line designed for versa...

Lab-scale chocolate chip depositor

Enhance your R&D capabilities with precision depositing of chocolate masses, allowi...

Chocolate quality analysis instrument

Ensure the highest quality of your chocolate production by precisely measuring contra...

Chocolate temper measurement device

Ensure your chocolate maintains optimal temper by measuring and analyzing the chocolate...

Laboratory cold-press chocolate shell maker

Enhance your R&D capabilities with a solution that enables precise cold-p...

Energy efficient chocolate tempering solution

Enhance your chocolate products with precise temperature control, reducing e...

Chocolate enrober for large scale production

Efficiently enrobe a wide range of products, from chocolate bars to delicate ...

Extruder and depositor for confectionery production

Ideal for producing sophisticated confectionery and bakery items, thi...

Depositing system for solid and filled chocolates

Enhance your chocolate production with a versatile depositing system, p...

Depositor for solid and filled chocolates

Optimize your chocolate production with precision depositing for medium to large...

Small scale chocolate enrober

Ideal for creative small-scale producers, this enrober allows you to experiment with chocolate...

Conveyor system for chocolate production lines

Streamline your production flow with this conveyor system, ensuring efficie...

Cooling unit for chocolate mass extrusion

Optimize your chocolate production by precisely cooling chocolate masses during ...

Industrial melting tank for chocolate and confectionery production

Maximize your production efficiency by seamlessly in...

Chocolate pump for consistent mass transport

Efficiently transport chocolate mass with precision, ensuring gentle handling...

Rotating stencil depositor for confectionery products

Streamline your confectionery operations by precisely depositing in...

Small scale chip depositor for confectionery production

Efficiently deposit a variety of confectionery and snack products...

Aeration and aroma mixing system for chocolate production

Optimize your chocolate and confectionery production with prec...

Chocolate quality measuring instrument

Ensure consistent chocolate quality by accurately measuring contraction, expansion, ...

Robotic chocolate assortment system

Streamline your chocolate production by precisely assorting various filled chocolate ar...

Accurate chocolate tempering measurement tool

Ensure precise chocolate tempering with real-time accuracy, enhancing qualit...

Automated bagging system for confectionery products

Achieve seamless integration in your confectionery packaging line wit...

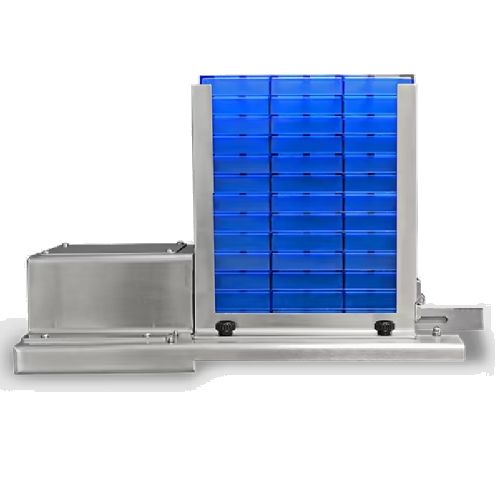

Plate and counter mould storage system for confectionery products

Streamline your confectionery production with an effi...

Flexible high-speed wrapping machine for chocolate products

Optimize your confectionery production line with a flexible ...

Wrapping system for preformed products in double twist

Achieve precise packaging with our high-speed double twist wrappin...

High-speed chocolate wrapping system

Optimize your confectionery packaging process with a versatile, high-speed wrapping so...

Ultrasonic food cutting equipment

Experience precise and efficient ultrasonic cutting of various food products, optimizing ...

Confectionery rework tempering solution

Improve confectionery production efficiency by integrating a compact rework temperi...

Praline and bar product take-off system

Streamline your confectionery production with a versatile take-off system designed ...

All around sprinkling systems for confectionery

Enhance your confectionery production with a system that ensures precise a...

Compact chocolate enrobing system

Achieve perfect chocolate coatings in minimal space with precise control, enabling high-q...

Enrobing system for full, half, and bottom coating of chocolates

Achieve precise and consistent chocolate coating with a...

Cooling tunnel for center cooling in confectionery production

Efficiently manage center cooling in confectionery product...

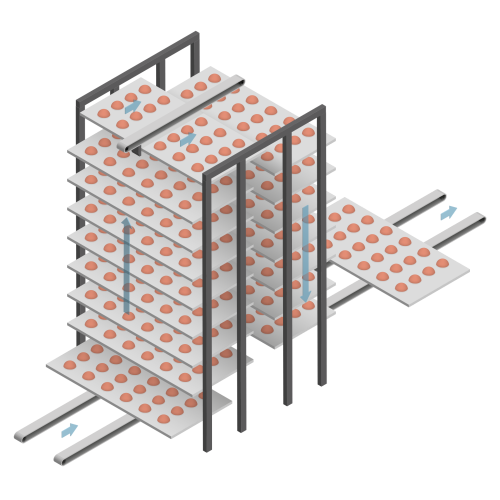

Vertical tunnel for cooling and moulding chocolate

Efficiently manage chocolate temperature control and molding precision...

Professional chocolate tempering system

Enhance your chocolate production with a versatile tempering system that optimizes ...

Automatic chocolate mould loader

Streamline your chocolate production with seamless mould loading, optimizing efficiency in ...

Chocolate tempering solution for small scale production

Efficiently temper chocolate for diverse confectionery creations ...

Chocolate and sugar coating system

Achieve consistent, high-quality coating for nuts, dried fruits, and confectionery with ...

Flowpack packaging machine for chocolate products

Effortlessly wrap and preserve large quantities of chocolate and sweet ...

Chocolate enrobing, moulding, and cooling tunnel

Optimize your chocolate production with this advanced tunnel, designed fo...

Chocolate enrobing system for tempering machines

Achieve consistent, high-quality chocolate coatings for your truffles, pr...

Chocolate enrobing and cooling tunnel 300/400 mm

Ensure seamless enrobing and precise cooling for chocolate products with ...

Carton Tray Forming Machine for Biscuits

Trays used as packaging for products for biscuits, cookies, chocolates and other s...

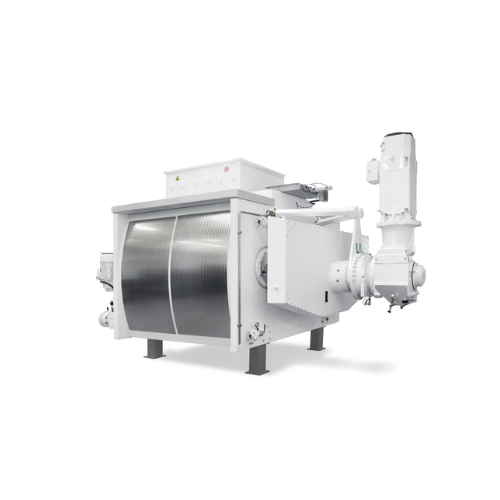

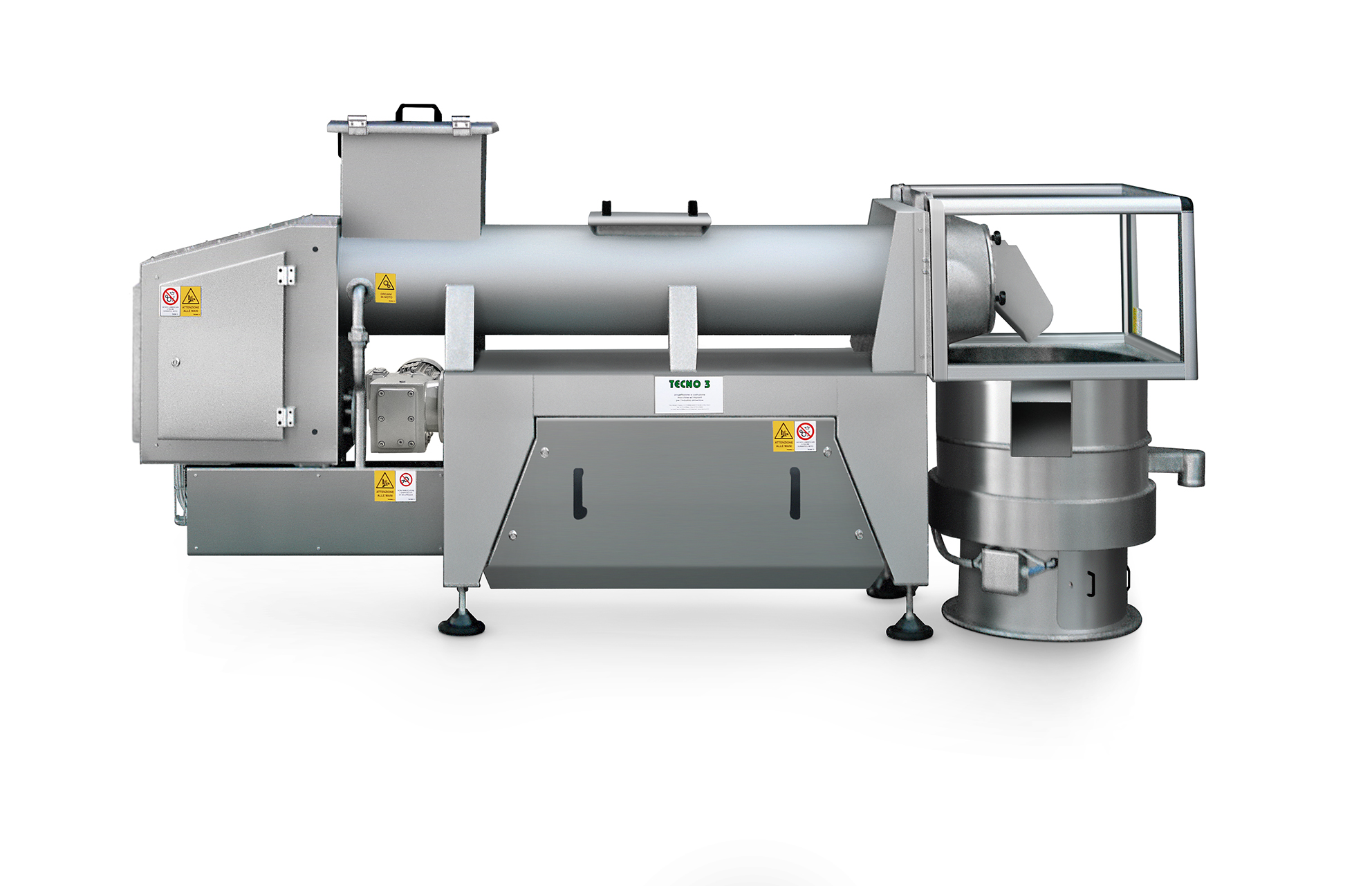

Mixer for production of chocolate with inclusions

Using the same mixing equipment for different recipes in chocolate manu...

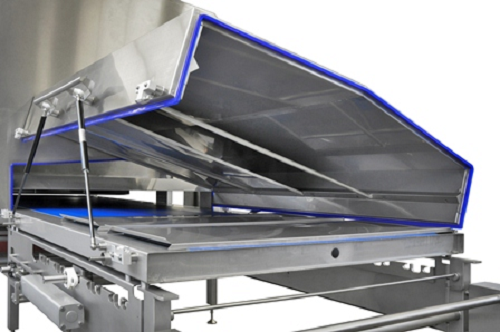

Refining plant for chocolate

Achieving a balanced, velvety mouthfeel in chocolate is challenging. Larger particles in chocol...

Industrial melter for chocolate rework

Wastage or out-of-specification products are not uncommon in the chocolate manufactu...

High-speed chocolate block melt machine

If you produce chocolate using larger blocks instead of cocoa beans, chocolate melt...

Entry level cocoa roaster

The biggest challenge that small-scale cocoa processing manufacturers face is even and thorough ro...

High-speed bunch wrapping machine for chocolate

Bunch wrapping with aluminium foil is a popular method to use for an attra...

Small chocolate tablet wrapping machine

Are you looking for a small-scale wrapping machine that can pack small Neapolitan c...

Mini sugar coating machine

The coating of grains or nuts with sugar is a popular process in the manufacture of many bakery p...

Small capacity cocoa grinder

The first step of producing almost any kind of chocolate starts with grinding cocoa beans to ge...

Entry level bean to bar line

One of the challenges when setting up a small-scale cocoa processing factory is making all of t...

Flexible chocolate tablet wrapping machine

In the overcrowded and competitive confectionery industry, attractive chocolate...

Hygienic chocolate cooling tunnel

Quickly cool your product after cooking in preparation for further processing. This is a ...

High capacity tempering machine

Prepare chocolate mixes for application to your product as coatings. Enhance the attractiven...

Ice coating machine

Make consistent use of this high-quality, finish coat with your covered product. This is a coating machin...

Small scale cocoa beans processing machine

For the highest quality chocolate production, complete control of the entire pr...

Entry level bean-to-bar machine

The production of high-quality chocolate from the bean can often be out of the reach of smal...

Small capacity chocolate melangeur

In order to produce the finest of chocolate products, you need the cocoa nibs to be grin...

Vertical cooling tower for chocolate moulds

Used for cooling one-shot products or chocolate blocs.

Bagger with rotary jaw drive actuation

If you are looking for a compact packing machine that fits into tight space and tigh...

System for continuous production of fondant or fondant crème

Fondant creme is used in the production of a range of confe...

Flexible mixing system for whipped cream and pastries

Delicacies such as meringue, ganache, and marzipan undergo various ...