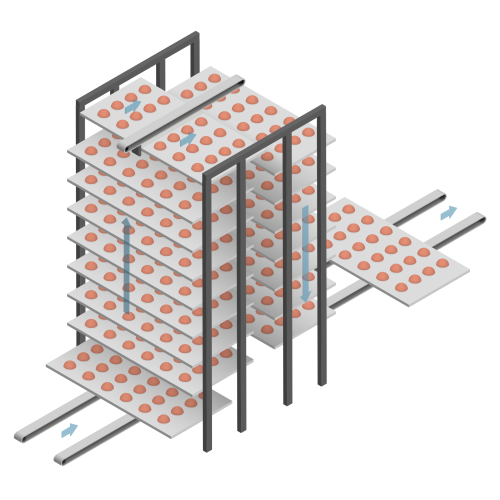

Plate and counter mould storage system for confectionery products

Streamline your confectionery production with an efficient system designed to handle and organize unwrapped products, ensuring smooth and continuous packaging operations while reducing handling time.

Transfers and Stores Confectionery Moulds and Products

The Plate and Counter Mould Storage System from Theegarten-Pactec is designed to enhance the efficiency and organization of your confectionery production line. This system specializes in the orderly storage and transportation of unwrapped sweets and chocolates, enabling a constant flow towards packaging. It uses two vertical conveyors and a horizontal conveyor for seamless movement of counter moulds and plates, while an automated traveling transfer device ensures precise positioning at the highest occupied level. Ideal for snacks, sweets, and chocolate products, it supports multiple product types ranging from soft caramels to bubble gum balls. With high-speed automated operations, this system integrates effortlessly into various production setups, maintaining continuous throughput essential for large-scale producers. Its construction supports durability and ease of cleaning, making it a reliable addition to any confectionery manufacturing facility.

Benefits

- Ensures continuous production flow with automated transfer and storage.

- Reduces labor requirements through its seamless, high-speed operation.

- Enhances product handling efficiency by minimizing bottlenecks in the processing line.

- Easily integrates with existing packaging systems to optimize overall productivity.

- Supports diverse confectionery types, offering versatile application within the industry.

- Applications

- Soft caramels, Snacks, Hard candies, Fudge, Eclairs, Chocolate products, Toffee, Sweets, Jelly products, Bubble gum products, Preformed products, Chewing gum

- End products

- Butterscotch fudge squares, Mint gum pieces, Soft toffee squares, Fruit flavored gummy bears, Berry-flavored hard candies, Sugar-coated jelly beans, Caramel-filled chocolates, Bubble gum balls, Milk chocolate squares, Taffy strips, Fruit eclairs, Confectionery bars

- Steps before

- Processing, Moulding, Shaping, Forming

- Steps after

- Wrapping, Packaging, Distribution

- Input ingredients

- plates, counter moulds, unwrapped products, bulk products, hard caramels, jelly products, chocolate balls, eggs, confectionery products

- Output ingredients

- wrapped products, packaged products, organized confectionery products, smooth packaging process flow

- Market info

- Theegarten-Pactec is known for its expertise in manufacturing highly specialized packaging machines for small-sized confectionery products, offering innovative, flexible, and efficient solutions tailored to various customer needs in the industry.

- Handling System

- Vertical, Horizontal Conveyors

- Automation

- Automatic positioning of transfer device

- Transfer Device

- Travelling transfer device

- System Configuration

- Integrated with conveyor systems

- Storage Capacity

- Plates and Counter Moulds

- Working mechanism

- Vertical conveyor transfer

- Integrated steps

- Unwrapped product handling and transport

- Automation level

- Automatic positioning of transfer device

- Batch vs. continuous operation

- Continuous

- Changeover time

- Automatic adjustment

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Vertical conveyors

- 2

- Storage system design

- Plate and counter mould

- Transfer device

- Travelling transfer device

- Level positioning

- Automatic

- Integration with vertical conveyors

- Yes

- Transfer device positioning

- Automatic

- Conveyor type

- Vertical and Horizontal

- Horizontal conveyor integration

- Yes

- Customization for product type

- Counter moulds and plates