Industrial chocolate ball mill for uniform grinding

Achieve precise chocolate particle refinement with this robust ball mill, ensuring optimal texture and flavor consistency, key for producing high-quality confections.

Pre-Mixes Ingredients for Chocolate Production

The MKOH-A-1650-3 Pre-Mixer System from Memak is designed for the precise pre-mixing of ingredients in chocolate production, ensuring uniform consistency and quality. This system integrates seamlessly into your production line, enhancing the initial stages of chocolate processing by combining solids and liquids to form a homogenous slurry. This equipment supports processors in manufacturing chocolate bars, filled chocolate cups, and more. With continuous, automatic operation, it enhances throughput while minimizing manual intervention. The system is PLC-controlled, allowing for easy integration and remote monitoring. Built with robust materials, it withstands the rigors of confectionery environments, and its modular design eases cleaning and maintenance. Options for customization and engineering support are available to tailor the system to specific production needs.

Benefits

- Enhances product consistency through precise ingredient pre-mixing.

- Increases production efficiency with continuous, automated operation.

- Simplifies integration into existing lines with PLC control and remote monitoring.

- Reduces maintenance time with easy-to-clean, modular design.

- Customizable to meet specific production requirements and volumes.

- Applications

- Cereal bars, Sweets, Bakery products, Nougat, Chocolate, Soft candy

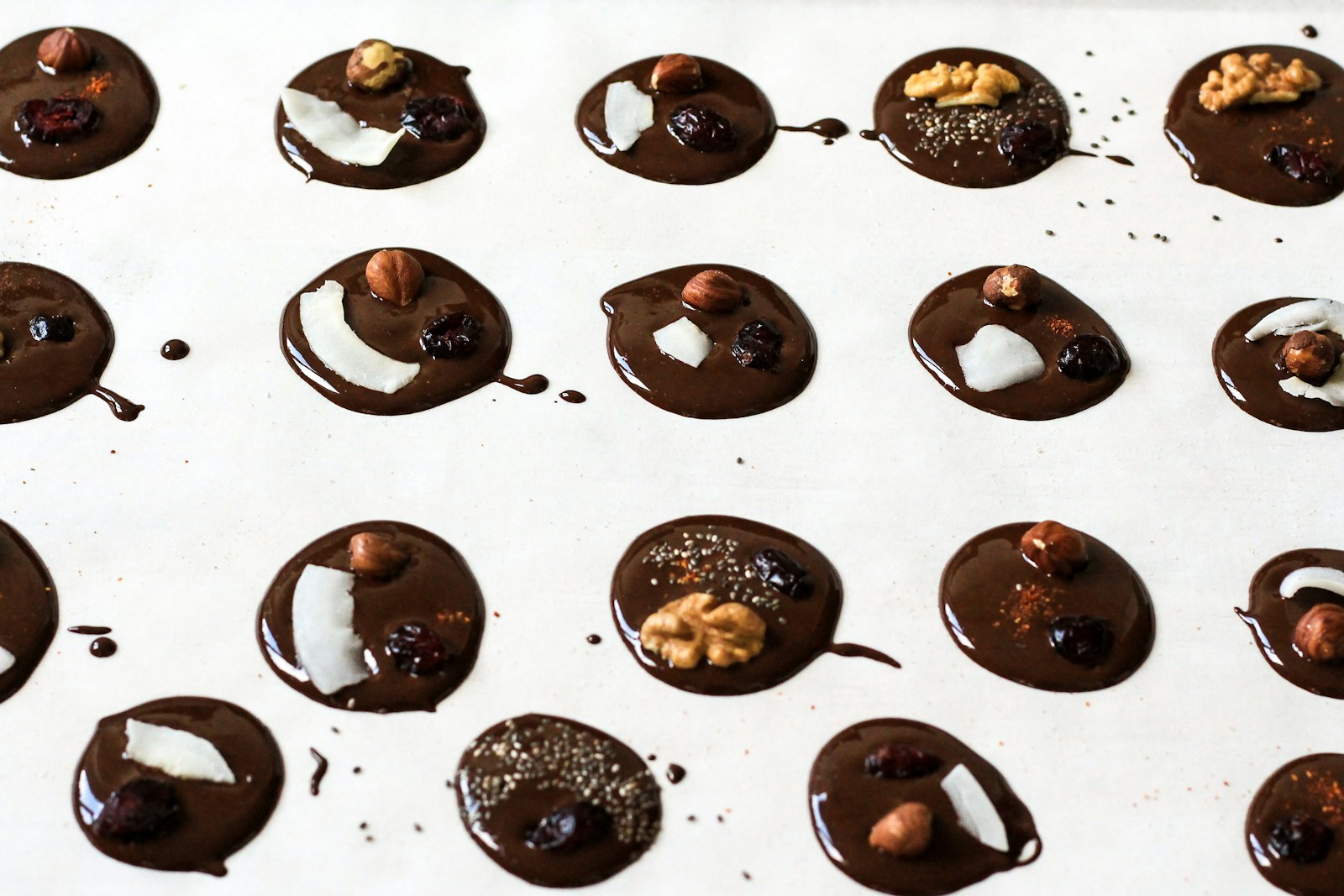

- End products

- Chocolate shells, Nougat bars, Filled chocolate cups, Jelly-filled chocolates, Whipped chocolate products, Baton chocolates, Neapolitan chocolates, Chocolate bars, Chocolate coated bars, Madlen chocolates, Chocolate drops, Soft candies, Chocolatin chocolates

- Steps before

- Raw Material Preparation, Fat Melting, Sugar Grinding, Pre-mixing

- Steps after

- Tempering, Moulding, Cooling, Wrapping, Filling

- Input ingredients

- raw materials, sugar powder, fat, chocolate, glucose, invert sugar, condensed milk

- Output ingredients

- chocolate products, chocolate bars, chocolate shells, cereal bars, nougat, soft candy

- Market info

- Memak is known for manufacturing high-quality, engineered-to-order equipment primarily for the food processing industry, with a reputation for innovation, precision engineering, and reliable customer support.

- Automation

- PLC-controlled

- Capacity

- 50–2000 kg/h

- Batch size

- 5–100 kg

- Cooling temperature

- 4–15°C

- Filling volume

- 250 ml – 2 L

- Abrasion resistance

- Yes/No

- Energy Usage per Batch

- 5–25 kWh

- Working mechanism

- Ball mill / Continuous mill / Pre-Mixer

- Automation level

- Automatic / Manual

- Batch vs. continuous operation

- Batch / Inline Continuous

- Integrated steps

- Melting, Mixing, Tempering

- Changeover time

- Minimized with automated systems

- CIP/SIP

- CIP available

- Energy efficiency

- Optimized for high performance

- Cleaning method

- CIP / Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Temperature control

- Precision

- Machine footprint

- Varies by model

- Tank shape/size

- Depends on specific machine type

- Feed/discharge method

- Automatic/Manual, depends on model

- Compact footprint

- Customized

- Control panel type

- Touchscreen or Manual

- Discharge method

- Automatic/Manual

- Control panel type

- Touchscreen / HMI

- Integration possibilities

- SCADA / PLC

- Compact footprint

- Yes

- Discharge method

- Automatic / Manual

- Cooling option

- Ambient / Chilled