Tempering Equipment

Find innovative tempering equipment and connect directly with world-leading technology suppliers

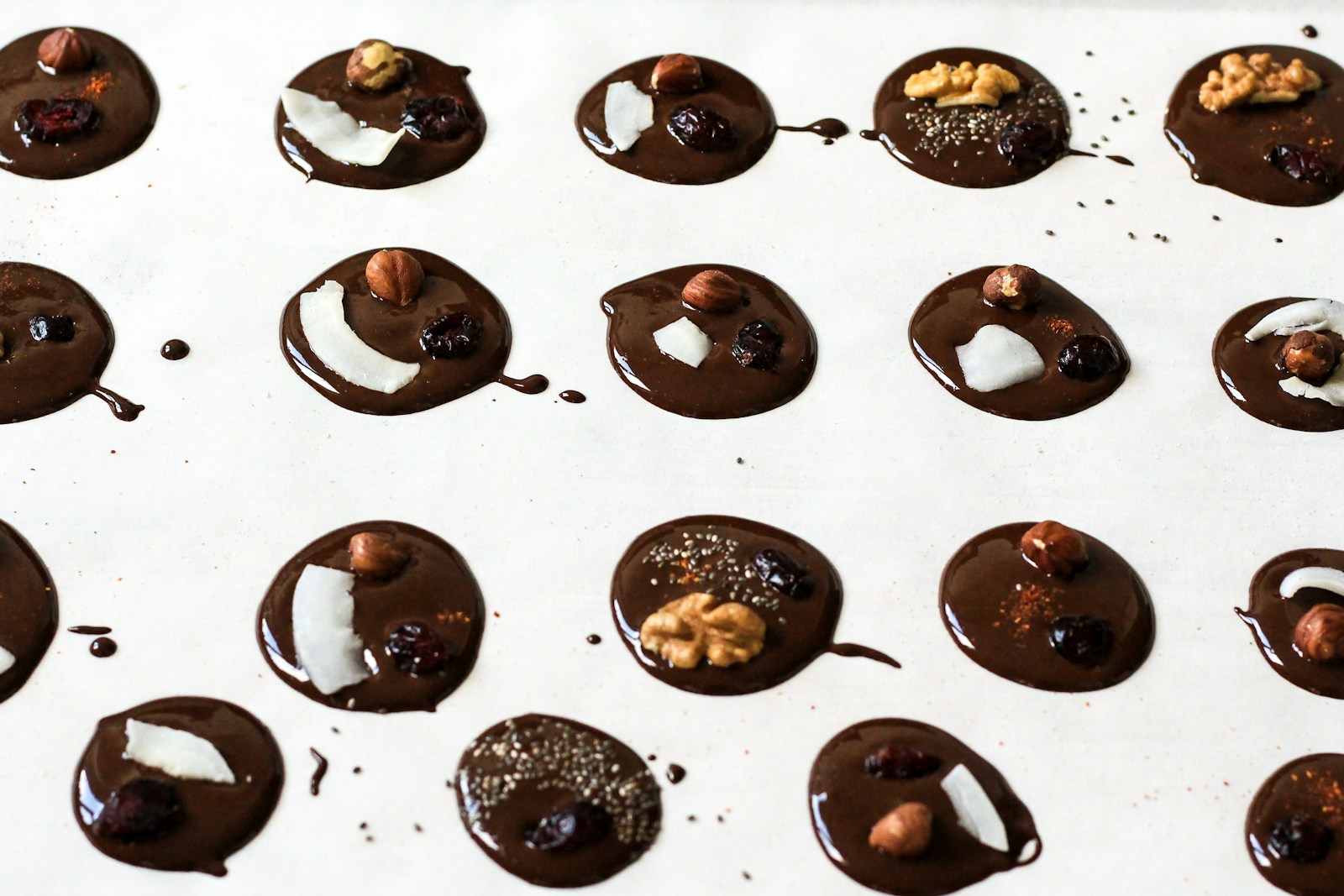

Tempering equipment is most commonly used in manufacturing chocolate products as well as bakery products. However, tempering can also be found in the metals industry for processing alloys. The idea behind the tempering process is to heat two or more items to a certain temperature so that they can be blended together easier. Chocolatiers pass the chocolate through a heating cycle and then a cooling tunnel to give their final products a smooth and glossy finish. Tempering machines automate this process, evenly distributing the crystal structure in melted chocolate across the entire production line. Besides enhancing the look and texture of coatings, denser and consistent crystallization also has the benefit of slowing down fat migration in your chocolate-filled products. A vibrating table is an important component for tempering chocolate. First the chocolate mixture goes through a dispenser into the chocolate mould. After which the vibrating table is used to evenly distribute the mixture in the mould so that there are no air bubbles. Thus, creating a smooth and consistent final product.

What are you making?

Aerated chocolate

Chocolate bonbons

Candy bars

Candy coatings

Cannabis candy

Cannabis edibles

Chocolate balls

Chocolate bars

Chocolate chips

Chocolate coatings

Chocolate couverture

Chocolate decorations

Chocolate dragees

Chocolate drops

Chocolate eggs

Chocolate ganache

Chocolate molds

Chocolate pralines

Chocolate truffles

Cocoa mass

Confectionery coatings

Dark chocolate

Durum wheat semolina

Hazelnut spread

Ice cream

Margarine

Milk chocolate

Nougat

Truffle balls

Truffles

White chocolate

Wine bottles

Which tempering technology do you need?

Chocolate tempering system for mould filling and vibrating

Ensure a flawless finish for chocolates and confections with ...

Continuous tempering machine for chocolate production

Streamline your chocolate production with precise tempering, ensuri...

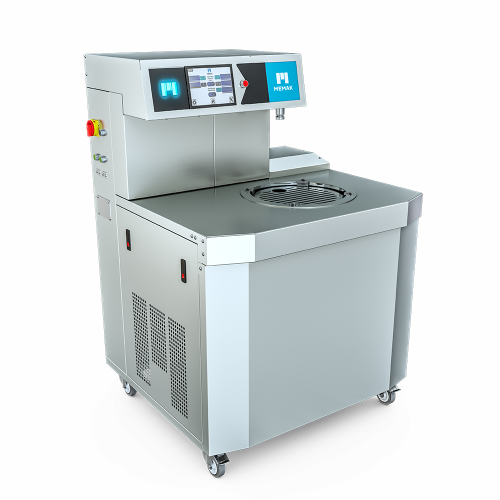

Compact chocolate tempering solution

Enhance your chocolate products’ finish and efficiency: this compact solution en...

Batch tempering solution for chocolate production

Achieve precise temperature control for chocolate consistency and quali...

Chocolate tempering solution for industrial production

Achieve consistent chocolate crystallization with a machine that e...

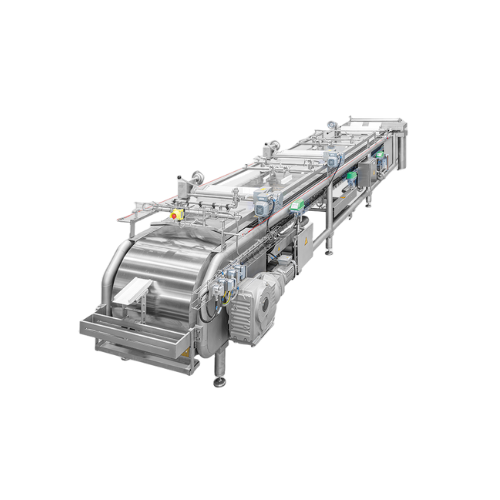

Industrial chocolate tempering belt

Achieve precise mass tempering for diverse confectionery textures with a stainless-stee...

Chocolate tempering system

Optimize your chocolate production with a tempering system that achieves precise crystallization,...

Advanced chocolate tempering system

Achieve flawless chocolate and confectionery products with precision tempering, ensurin...

Energy efficient chocolate tempering solution

Enhance your chocolate products with precise temperature control, reducing e...

Laboratory chocolate tempering solution

Achieve precise tempering of diverse chocolate and confectionery masses with optimi...

Bakery refrigeration systems for controlled dough tempering

Achieve consistent bakery quality by precisely controlling y...

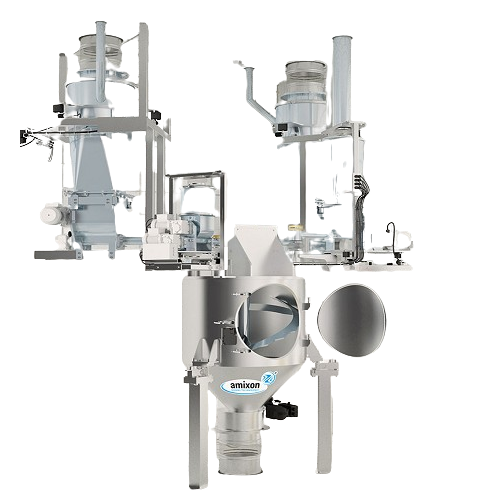

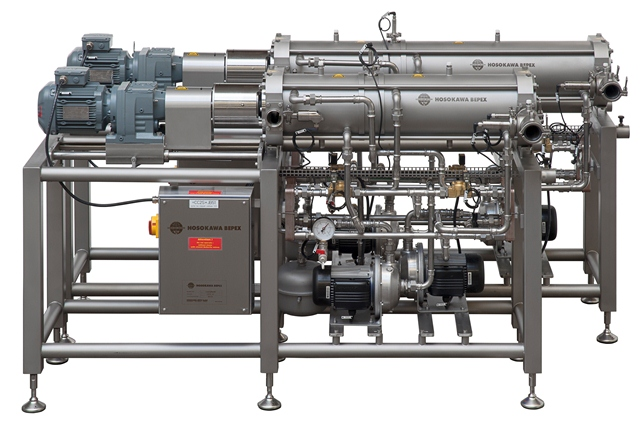

Blending machine for pre-grinding or tempering processes

Optimize your grain processing with precise blending and mixing ...

Nougat tempering system for consistent viscosity

Achieve consistent quality and precision in praline centers and nougat ba...

Confectionery rework tempering solution

Improve confectionery production efficiency by integrating a compact rework temperi...

Chocolate tempering solution for superior gloss and shelf life

Achieve consistent sheen and extend the shelf life of cho...

Integrated tempering enrober for chocolate coatings

Enhance your chocolate production line with an integrated solution fo...

Professional chocolate tempering system

Enhance your chocolate production with a versatile tempering system that optimizes ...

Professional chocolate tempering system for chocolatiers

Achieve precise chocolate tempering with advanced digital contro...

Professional chocolate tempering system for artisan chocolatiers

Achieve precise chocolate tempering with quick changeov...

Chocolate tempering solution for small scale production

Efficiently temper chocolate for diverse confectionery creations ...

Professional chocolate tempering equipment for efficient production

Enhance your production capabilities with a versati...

Chocolate enrobing system for tempering machines

Achieve consistent, high-quality chocolate coatings for your truffles, pr...

Professional chocolate tempering solution for large workshops

Enhance your chocolate production efficiency with a machin...

Chocolate enrobing belt for tempering machines

Enhance your chocolate production line with precise control over coating an...

High capacity tempering machine

Prepare chocolate mixes for application to your product as coatings. Enhance the attractiven...

Automatic continuous tempering machine

Very powerful and easy-to-use automatic tempering machine, for artisan chocolatiers....

Enrobing attachment for an automatic tempering machine

Used in the confectionery industry to coat nuts, ice cream, toffee...

Batch tempering machine for chocolate and fillings

Ideal for tempering chocolate-based fillings and flavored chocolate ba...

Industrial mini-tempering machine

Mainly used to feed enrobers, small depositors and decorating systems.

Automatic batch tempering machine

Automatic tempering machine, for batch process in a medium scale production.

Automatic continuous tempering machine with pump

Continuous tempering machine for medium scale process.

Chocolate moulding system for small-scale production

Optimize your chocolate production by efficiently melting, tempering...

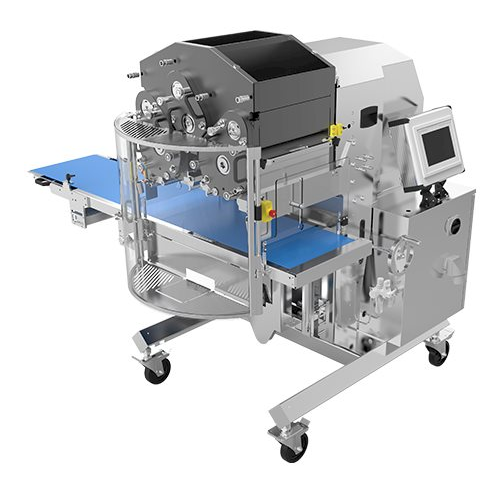

Pneumatic scrapers for chocolate mould filling

Achieve precise chocolate moulding with pneumatic scrapers that streamline ...

Chocolate moulding system for small batch production

Streamline your chocolate product line with precision moulding and t...

Compact chocolate moulding system

Optimize your chocolate creations with a compact system designed for easy melting, temper...

Stainless steel chocolate tank for storage and processing

Efficiently control temperature and consistency for chocolate ...

Cooking extruders for low shear confectionery production

For producers looking to create high-quality confectionery, this...

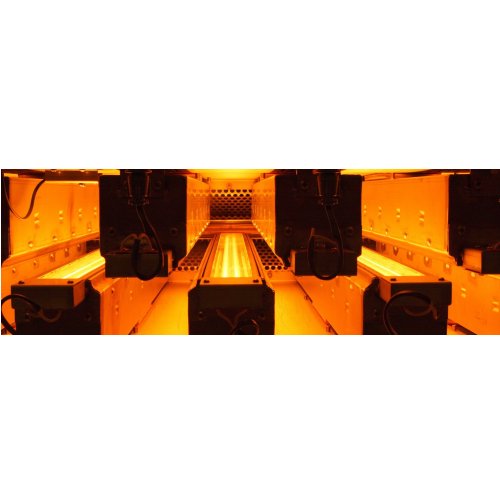

Infrared dryers and ovens for coating and substrate processing

Achieve precise drying and curing with customizable infra...

Heat exchanger for corrosive substance handling

Optimize your process of handling corrosive substances with a heat exchang...

Hard candy production system

Enhance your candy production line with a comprehensive system that optimizes processes from co...

Crystallization process for chewy candy production

Optimize your confectionery production with precision crystallization,...

Fondant mass production system

Achieve precise crystal size and uniform fondant quality with a two-step crystallization proc...

Forming line for croquant, hard candy, and chewy candies

Optimize your candy production with precision forming and emboss...

Continuous butter toffee processing system

Achieve precise caramelization and nut integration while maintaining the perfec...

Rapid cooling oven for thermo-luminescent dosimeters

Achieve precise thermal processing with rapid temperature cycling, i...

Premixer for confectionery masses

Achieve consistent ingredient blending with precision-premixing for candy and baked goods...

Continuous moulding line for chocolates

Achieve precise chocolate moulding with continuous operation, ensuring high-speed p...

Premixer for cream production

Achieve precise mixing of liquid and solid fats for diverse cream formulations with insulated ...

Continuous powder mixer for dry, moist and suspended goods

Achieve precise homogenization and deagglomeration with a con...

Chocolate quality analysis instrument

Ensure the highest quality of your chocolate production by precisely measuring contra...

Chocolate temper measurement device

Ensure your chocolate maintains optimal temper by measuring and analyzing the chocolate...

Crystallization and aeration unit for fat-based center masses

Efficiently manage the crystallization and aeration of fat...

Enrobing system for rapid changeover in confectionery production

Achieve seamless chocolate coating transitions with a s...

Chocolate quality measuring instrument

Ensure consistent chocolate quality by accurately measuring contraction, expansion, ...

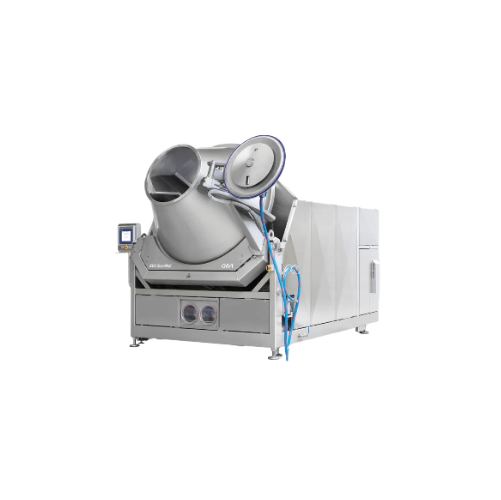

Industrial defrosting and mixing for frozen raw materials

Reduce frozen material tempering time from hours to minutes, e...

Industrial defrosting technology for meat products

Achieve efficient defrosting and tempering of meat and poultry with va...

Chocolate decoration systems for confectionery production

Enhance your confectionery production with precision chocolate...

Chocolate lentil, ball, and egg production system

Achieve consistent and precise shaping of chocolate lentils, balls, and...

Compact chocolate enrobing system

Achieve perfect chocolate coatings in minimal space with precise control, enabling high-q...

Enrobing system for full, half, and bottom coating of chocolates

Achieve precise and consistent chocolate coating with a...

Simultaneous chocolate and ice cream dispenser

Unite the worlds of chocolate and ice cream with a machine capable of seaml...

Chocolate enrobing, moulding, and cooling tunnel

Optimize your chocolate production with this advanced tunnel, designed fo...

Chocolate and nut cluster production line

Optimize your confectionery production with precise control over chocolate and n...

Bean to bar chocolate production equipment

Transform cocoa beans into exquisite single-origin chocolate with complete cont...

Chocolate drops production system

Create perfectly uniform chocolate drops with precision dispensing and seamless integrati...

Entry level bean to bar line

One of the challenges when setting up a small-scale cocoa processing factory is making all of t...

Entry level bean-to-bar machine

The production of high-quality chocolate from the bean can often be out of the reach of smal...

Chocolate bean to bar line 10kg

Developing new products, producing specialty chocolates, laboratory testing, and in-shop pro...

Chocolate bean to bar line 200kg

Installing a chocolate production line that works efficiently and smoothly can be a dauntin...

Compact chocolate moulding solution 3-in-1

Streamline your confectionery creations with a versatile 3-in-1 machine that se...

Industrial chocolate ball mill for uniform grinding

Achieve precise chocolate particle refinement with this robust ball m...

Intermediate cream container for snack production

Ensure consistent cream texture before extrusion with a solution design...

Chocolate refining five-roll refiner

Achieve optimal chocolate texture with high-efficiency refining, reducing energy usage...

Scraped surface heat exchanger for high viscous products

Efficiently handle the cooling and heating of high viscous produ...

Roll support dryers for web transportation

Eliminate web curl issues and enhance drying precision for diverse materials wi...

Liquid confectionery metering system

Effortlessly integrate precision and flexibility in candy production by accurately met...

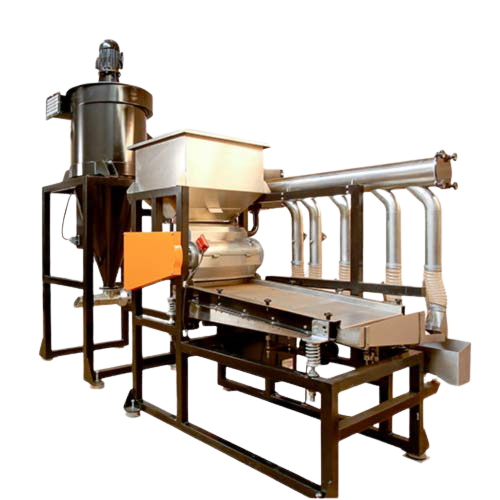

Powder mixing and metering system for confectionery production

Optimize your confectionery production by seamlessly blen...

Batch weighing system for precise ingredient metering

Optimize your confectionery production with a system that reduces s...

Continuous caramel cooker for candy production

Achieve perfect caramel consistency with precise control as this solution c...

Batch cooker for lab or small test production runs

Optimize your lab-scale confectionery trials with a versatile batch co...

Aerator for candy masses

Enhance your candy production with precise and efficient aeration, transforming textures and creatin...

Aeration system for sugar masses

Optimize your production of aerated confectioneries with a two-step aeration system designe...

Mixing and metering system for candy production

Achieve precise ingredient integration and optimal blending for diverse co...

Continuous caramelization system for protein-containing sugar masses

Achieve precise caramelization for a wide range of...

Batch cooker for confectionery masses

Effortlessly cook a variety of confectionery masses, like caramel and jelly, with pre...

Vacuum chamber furnace with metal insulation

Achieve high-temperature processing with precision and purity using advanced ...

Split tube furnace for high-temperature applications

Enhance your thermal processing operations with a split tube furnace...

Top hat industrial furnace for high-temperature applications

Achieve precise high-temperature processing with this advan...

High temperature chamber furnace for sintering ceramics

Achieve precise thermal consistency for high-temperature applicat...

Advanced superheated steam drying solution

Harness the power of consistent drying technology to achieve optimal moisture c...

Ball mill for chocolate, cocoa, and nut products

Optimize your grinding processes and achieve perfect product consistency ...

Cooling conveyor for baked goods

Efficiently adapt your baked and confectionery goods to ambient conditions, ensuring optima...

Turbo cream mixer for fat cream production

Achieve consistent and homogeneous cream fillings quickly with this advanced hi...

Extruder and depositor for protein bar manufacturing

Streamline your protein and energy bar production with an advanced e...

High capacity chocolate moulding line

Maximize your production capacity with a tailor-made moulding line designed for versa...

Lab-scale chocolate chip depositor

Enhance your R&D capabilities with precision depositing of chocolate masses, allowi...

Laboratory roller for chocolate production

Easily switch between producing chocolate lentils, balls, and eggs with these f...

Laboratory cold-press chocolate shell maker

Enhance your R&D capabilities with a solution that enables precise cold-p...

Flexible depositor and extruder for small-scale production

Achieve precise multi-mass creations with a compact, versatil...

Small-scale chocolate enrober for laboratory use

Optimize small-scale chocolate production with a flexible enrober designe...

Industrial chocolate enrober

Achieve exceptional chocolate coating consistency and efficiency with this advanced enrobing te...

Conveyor system for chocolate production lines

Streamline your production flow with this conveyor system, ensuring efficie...

Industrial melting tank for chocolate and confectionery production

Maximize your production efficiency by seamlessly in...

Chocolate pump for consistent mass transport

Efficiently transport chocolate mass with precision, ensuring gentle handling...

Small scale chip depositor for confectionery production

Efficiently deposit a variety of confectionery and snack products...

Depositor and extruder for confectionery production

Enhance productivity with precision depositing and flexible extruding...

Aeration and aroma mixing system for chocolate production

Optimize your chocolate and confectionery production with prec...

Chocolate decoration stringer for bakery and confectionery

Elevate your confectionery creations with precision chocolate...

Twin-shaft mixer for food preparation

Achieve optimal protein extraction and ingredient distribution with this twin-shaft m...

Automated grain blending system

Achieve precise blending ratios for grains and seeds, streamlining your production line by a...

Lay-on systems for precise sprinkling and nut depositing

Optimize your confectionery production with precision sprinkling...

Sprinkling system for decorating confectionery products

Enhance your confectionery line with precision sprinkling systems...

Decrystallization for tempered chocolate

Ensure your chocolate is perfectly smooth and free of fat crystals with an advance...

Praline and bar product take-off system

Streamline your confectionery production with a versatile take-off system designed ...

All around sprinkling systems for confectionery

Enhance your confectionery production with a system that ensures precise a...

Automated chocolate decoration system

Elevate your confectionery production with precision chocolate decoration, seamlessly...

Continuous bar production line for confectionery

Streamline your confectionery production with a seamless system for craft...

Chocolate shell molding system

Optimize your confectionery production with precision shell formation, enabling diverse and i...

Volume-precise moulding for chocolate and fat masses

Achieve precise and consistent moulding for chocolate and confection...

Forming system for cereal bars and nut mixes

Effortlessly transform diverse ingredients like cereals and nuts into precise...

Flavour and colour dosing system

Simplify production by efficiently incorporating various flavors, colors, and solid inclusi...

Caramel enrobing system for biscuits and wafers

Achieve consistent caramel coverage with precise temperature control, ensu...

Retractable mass carriage enrober for chocolate coating

Improve production flexibility with a versatile enrober that allo...

Enrobing system for biscuits and baked goods

Achieve consistent and precise chocolate coatings with the versatility you ne...

High pressure plunger pump for continuous food processing

Achieve consistent texture and quality in spreads and sauces w...

High capacity compound conditioner

Enhance the appearance of coatings applied to your product by control the crystal compos...