Industrial defrosting technology for meat products

Achieve efficient defrosting and tempering of meat and poultry with vacuum steam technology, minimizing drip loss and enhancing yield.

Defrosts and Tempers Meat Using Vacuum Steam

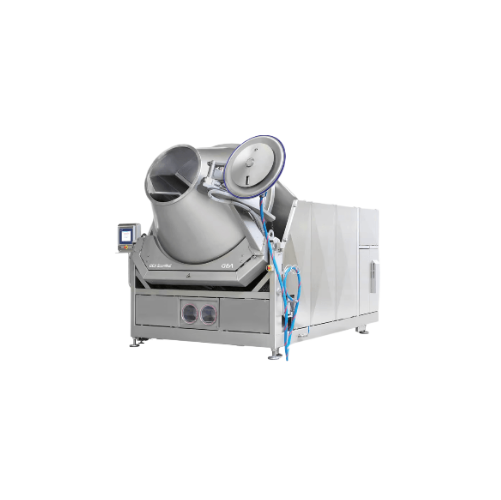

The GEA ColdSteam T by GEA Group is an innovative vacuum steam tumbler designed for industrial meat defrosting and tempering. This equipment stands out for its ability to efficiently defrost meat products like pork bellies and chicken fillets by leveraging steam in a near vacuum environment, significantly reducing drip loss and contamination risk. Operating with a 95% vacuum, it provides safe defrosting while preserving the meat’s textural integrity and natural juices.

The ColdSteam T is versatile, handling processes such as defrosting, tempering, marinating, and tumbling in one machine. Suitable for food, meat, and poultry processing industries, it supports a variety of applications—from pork spare ribs to chicken nuggets—by controlling the process from -20°C to +2°C.

Engineered for batch and automated operations, it integrates seamlessly into existing production lines with optional marination functions, minimizing handling and accelerating processing times. Available in different capacities, from 2500 L to 10000 L, it caters to diverse production demands with power ratings from 10 kW to 22 kW. The tumbler’s simple physics principle, where steam condenses on frozen meat, speeds up defrosting by up to 70% while maintaining optimal energy efficiency.

Constructed for minimal human contact and ease of cleaning, the ColdSteam T supports food safety with its closed environment, inhibiting microbiological growth. With ongoing engineering support and customization options, it adapts to specific operational needs, ensuring optimal integration and performance in any meat processing workflow.

Benefits

- Enhances product yield by preventing drip loss and retaining valuable proteins.

- Increases throughput with rapid defrosting and tempering, cutting process time by up to 70%.

- Minimizes contamination risk with a closed vacuum environment, ensuring food safety.

- Reduces handling steps with integrated marination and tumbling functions.

- Saves energy and operational costs through efficient vacuum steam technology.

- Applications

- Chicken nuggets, Meat products, Poultry products, Sausages, Patties, Processed meat products, Beef products, Pork products

- End products

- Chicken breast fillets, Beef topside, Pork spare ribs, Chicken fillet, Pork bellies, Bone-in poultry parts

- Steps before

- Freezing, Portioning, Packaging

- Steps after

- Marination, Mixing, Tempering, Forming, Cooking, Packing

- Input ingredients

- frozen meat, chicken breast fillets, bone-in poultry parts, pork spare ribs, beef topside, frozen raw material

- Output ingredients

- defrosted meat, tempered meat, homogenous mix, formed products, sausages, patties, chicken nuggets

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Defrost system

- ColdSteam technology

- Capacity

- 2500–10000 L

- Electric power

- 10–22 kW

- Size

- 3500x1870x3050 mm to 5600x2740x4350 mm

- Machine weight

- 2800–6600 kg

- Boiling point

- 33°C in 95% vacuum

- Cycle time

- 70% quicker than conventional methods

- Working mechanism

- Steam under vacuum

- Integrated steps

- Defrosting and marinating

- Batch vs. continuous operation

- Batch

- Automation level

- PLC controlled

- CIP/SIP

- Easy to clean with no hidden corners

- Changeover time

- Fast due to automated control

- Energy efficiency

- Uses less energy due to vacuum process

- Cleaning method

- CIP

- Drip loss prevention

- Yes

- Product type

- Meat and poultry

- Machine size

- Small/Medium/Large

- Machine footprint

- 3500x1870x3050 mm - 5600x2740x4350 mm

- Machine weight

- 2800 kg - 6600 kg

- Tumbler volume

- 2500 l - 10000 l

- Discharge method

- Vacuum tumble discharge

- Control panel type

- PLC-controlled

- Control panel type

- Touchscreen HMI / PLC

- Integration possibilities

- SCADA integration / Remote monitoring

- Customization of tumbler size

- 2, 500 L to 10, 000 L capacities

- Steam injection customization

- Bottom injection steam nozzles

- Variable wing speed

- Yes