Making Ice Cream

Find innovative production technology for making ice cream and connect directly with world-leading specialists

Making ice cream is all about mixing and homogenizing. First you need to blend, pasteurize and standardize your mixture. Then store it in tanks and freeze and aerate the mix until it reached the right consistency. Now you can add fruits, cookies and other solids if you like. In the final step the mix goes through an air blast hardening machine and it's ready to store and ship.

Stories about ice cream

Select your ice cream process

Tell us about your production challenge

Ice cream equipment to make that “cream” into “ice cream”

Good quality ice cream is a combination of taste and texture. You can achieve both with good ingredients and consistent processing methods. Production begins with mixing base ingredients like milk, cream, butterfat, and food additives such as stabilizers and emulsifiers. This mixture goes through a pasteurizer to remove harmful bacteria and a homogenizer to create a smooth and consistent texture. When properly homogenized, ice cream reaches that creamy texture we all crave, with flavors uniformly distributed.

From there, you can cool and age the mixture for about four to eight hours. This allows the milk fat to partially crystallize and improve its whipping properties. After the aging process, you can add other liquid flavorings. Then the mixture goes through a continuous freezer where air is mixed to make the ice cream lighter and easy to scoop. After that, you can add other bulky flavorings to the mix, like fruits, candies, cookies, etc. Once all ingredients are set, you can pour the ice cream into containers that will pass through a continuous blast air-hardening machine. Then you store it in a refrigerated facility until it is shipped.

Ice cream with a twist: dairy-free and gelato

The market has seen variations of ice cream such as dairy-free and gelato. To make dairy-free ice cream, you use milk substitutes like almond milk, soy milk, or coconut milk. These substitutes, however, may not have the same chemical properties as cow’s milk. So the ingredients and formulation are different, but the process is about the same. Other ice creams like gelato are rich in egg yolk solids and have less air. You can make them without stabilizers and emulsifiers, as the egg yolk serves this purpose. Having less air also means that your gelato will have a thick and rich texture.

Ice cream in supermarkets is mass-produced, made according to manufacturer’s standards. On the other hand, there are small-scale artisan ice cream makers who have their own ratio of mixed ingredients, but the process is the same. Differences reside on smaller ice cream equipment that suits their production capacity and in increasing some manual processes.

The details that make ice cream special

Ice creams come in different shapes. They are available in plastic tubs, cups, cones, and sticks. Some novelty ice cream products have decorations such as chocolate drizzles or sugar glaze as toppings. Others are shaped like objects or patterns depending on how the product is marketed. This is mostly applicable for ice cream sandwiches or ice cream with sticks. You can opt for decorations like coatings or separate layers as well. In some cases, you can even draw complicated shapes on the product using a drizzling machine for chocolate or other flavorings.

How do you want your ice cream served?

The hardening process of ice cream is critical to the final product’s structure and appearance. With it, the product should have the same appearance and structure as it arrives at the consumer with the proper refrigeration temperature. Different packaging may have an impact on the structure with regards to rigidity of the container and rate of exposure to higher temperatures. So be mindful of the storage temperature. Ice cream packed in plastic wrappers, such as ice cream sandwiches, ice cream and stick, and ice cream with cones, is much prone to melting when exposed to higher temperatures compared to ice cream in plastic tubs with lids.

Processing steps involved in ice cream making

Which ice cream technology do you need?

Rotary indexing sealer for cup filling

Streamline your production line with precise cup filling and sealing, ideal for a wi...

Industrial homogenizers for dairy products

Maximize consistency and quality in your production of milk products and bevera...

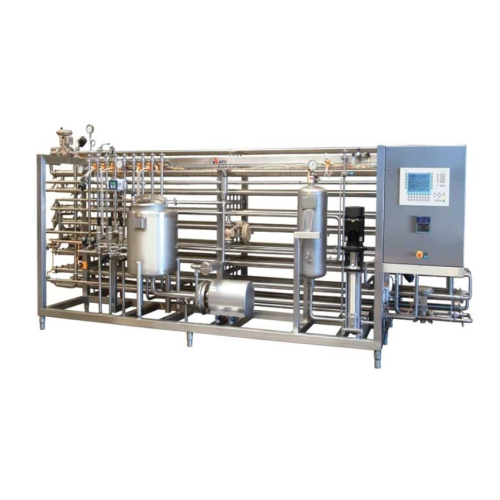

Milk pasteurizers for dairy sector

Ensure optimal safety and quality of your dairy products with advanced pasteurization te...

Compact chocolate moulding solution 3-in-1

Streamline your confectionery creations with a versatile 3-in-1 machine that se...

Mobile cleaning-in-place unit for process equipment

Ensure seamless cleaning of diverse process equipment with a mobile, ...

In-line production of fine emulsions

Achieve homogenous emulsions with precise control, reducing the risk of lump formation...

Aseptic buffer tanks for pilot scale process lines

Ensure seamless production flow and quality control in sterile environ...

Batch food processing cookers

Achieve precise temperature and pressure control for small-scale food production with modular ...

Advanced closed blending vessels for liquid food products

Enhance your production line with advanced closed blending ves...

Atmospheric blending vessel for r&d activities

Optimize your liquid blending processes with this versatile vessel, designe...

Hygienic buffer tanks for process optimization

Enhance your production flow with hygienic buffer tanks that ensure consist...

Pilot scale spray dryer for product development

Achieve precise moisture levels and product consistency in development env...

Lab Uht/htst system for r&d activities

Optimize your R&D with a versatile, modular system allowing precise control ove...

Laboratory in-line sterilization system

Ensure precise temperature control and rapid cooling for diverse liquid application...

Small-scale scraped surface heat exchanger for high-viscosity products

For R&D teams tackling complex formulations...

Uht/htst aseptic processor for pilot plants

Achieve precise heat treatment and aseptic processing with flexible pilot syst...

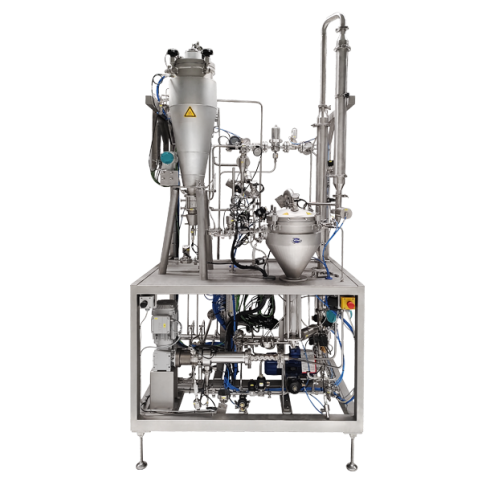

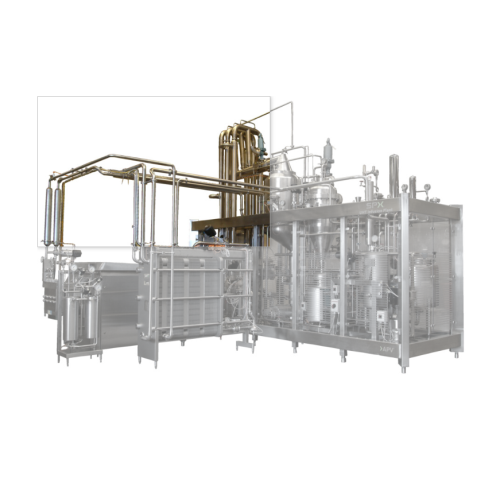

Direct steam injection Uht pilot system

Elevate your production capabilities with a sanitary UHT pilot system designed for ...

Direct steam infusion for high spore kill rate in sensitive food products

Achieve rapid, efficient sterilization and m...

Pilot system for high-viscosity product processing

Efficiently handle high-viscosity or large particle products with this...

Bench-top blending vessel for small batch preparation

For small-batch liquid products, achieve precise mixing, heating, a...

Lab-scale water bath blending vessel for product preparation

Ensure consistent flavor and quality across diverse small-s...

Lab-scale fermenter for simultaneous batch processing

Optimize your lab-scale fermentation process with a versatile solut...

Sterile filling and closing bench for bottles and cups

Ensure precise and sterile filling for liquid products with a hygi...

Cold aseptic filling solution for Uht samples

Ensure aseptic integrity and extend shelf life by securely filling and closi...

Aseptic filler for nutraceuticals

Ensure the sterility of your liquid nutraceuticals and beverages with a versatile solutio...

Aseptic bag-in-box filler for laboratory use

Achieve aseptic filling precision on a lab-scale with a compact solution that...

Fs closing devices for industrial packaging solutions

Streamline your packaging process with versatile closing devices, d...

Lab-scale high-pressure homogenization solution

Optimize your lab-scale production with precision homogenization, ensuring...

Pilot homogenizer for high-pressure inline homogenization

Achieve precise homogenization and emulsification across vario...

Small-scale in-container spray pasteurizer for laboratory use

Optimize your R&D processes with precise control over...

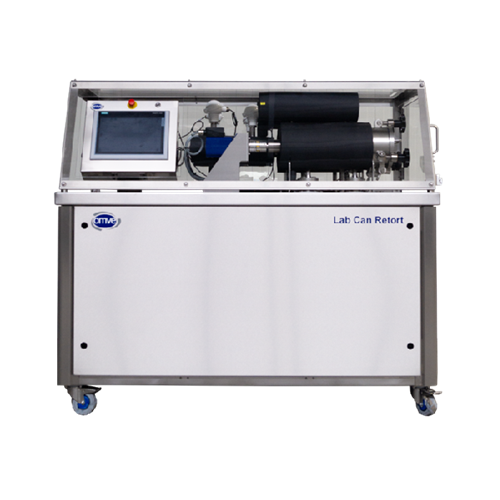

Lab can retort for precise temperature and pressure control

Achieve precision in recipe validation and packaging testing...

Direct steam injection system for heat treatment

Achieve precise thermal processing and enhance product quality for comple...

Manual Cip unit for lab and pilot plant cleaning

Need thorough cleaning without disassembling your pilot plant? This compa...

Cleaning in place unit for lab and pilot equipment

Streamline your lab and pilot-scale cleaning processes with a mobile, ...

Fully automated cleaning in place unit for food processing plants

Enhance food safety and streamline operations with a ...

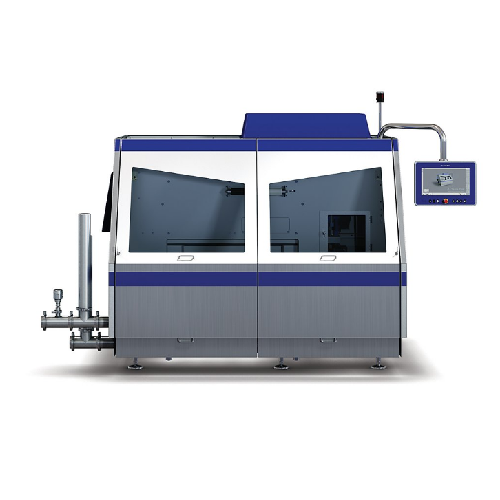

Continuous ice cream freezer for r&d

Achieve precise control of ice cream texture and consistency with a system that seamle...

Crystallizer for small-scale aeration and crystallization processes

Streamline your production with a versatile crystal...

Batch deaerator for reduced oxidation in liquid processing

Optimize product shelf life and quality by efficiently removi...

Continuous deaeration solution for laboratory and pilot systems

Achieve superior product stability and minimize foaming ...

Crown cork sealer for liquid food packaging

Ensure reliable sealing for bottled beverages and dairy with a compact, table-...

Counter-pressure filler for carbonated drinks

Enhance your carbonated beverage production with advanced counter-pressure f...

Customized process plants for plant-based beverages

Efficiently scale your production of plant-based beverages with modul...

Lab-scale carbonation system for beverage filling

Streamline your beverage development with precision carbonation and ver...

Carbonation and filling system for Pet and glass bottles

Optimize your beverage production with precise carbonation, fill...

Carbonation and can seaming solution for beverages

Optimize your beverage production with a seamless integration that sim...

Sterile carbonation system for beverages

Achieve precise carbonation for both common and specialty beverages with this vers...

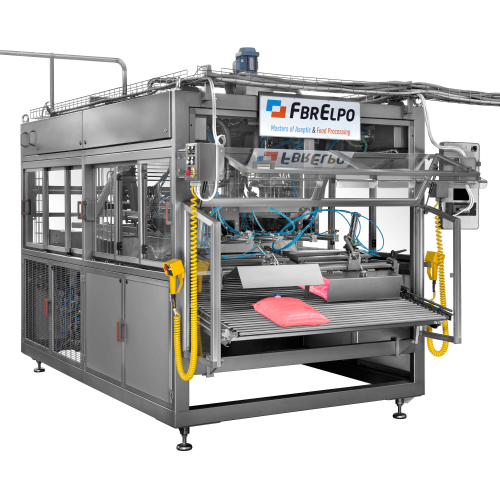

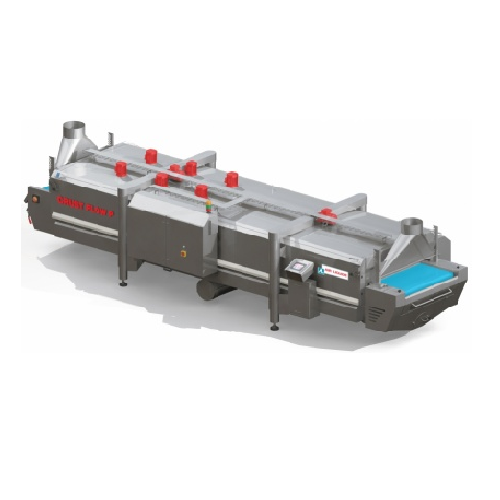

Horizontal stretch-film wrapping system for frozen food

Optimize your packaging line with a high-speed solution that secu...

Atmospheric fermenter for lab and pilot scale projects

Streamline your fermentation process with precise control over tem...

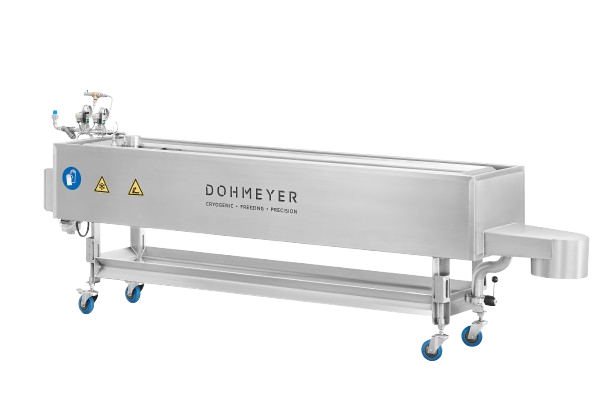

Cryogenic tunnel freezer for optimized food freezing

Enhance your production line with advanced cryogenic freezing techno...

Precision weighing tank for liquid and dry ingredient blending

Enhance your production line with precision control over ...

Cryogenic chilling system for meat processing

Ensure uniform temperature control in meat production lines to maintain prod...

Cryogenic freezer for food industry applications

Efficiently tackle high-speed freezing and chilling challenges with a ver...

Heating and cooling system for food and dairy products

Achieve precise temperature control and efficient processing with ...

High shear mixer for viscous powder dissolution

Need consistent, homogeneous blending of high-viscosity liquids and powder...

Inline high shear mixer for low to medium viscosity liquids

Efficiently dissolve large quantities of powders into liquid...

Industrial mixer for high shear mixing and emulsifying

Enhance your production line efficiency with versatile high shear ...

Inline mixer for uniform powder blends

Achieve uniform powder blends in minutes with this high shear inline mixer, designed...

Inline high shear mixing for dairy and condiments

Streamline your production line with innovative inline high shear mixin...

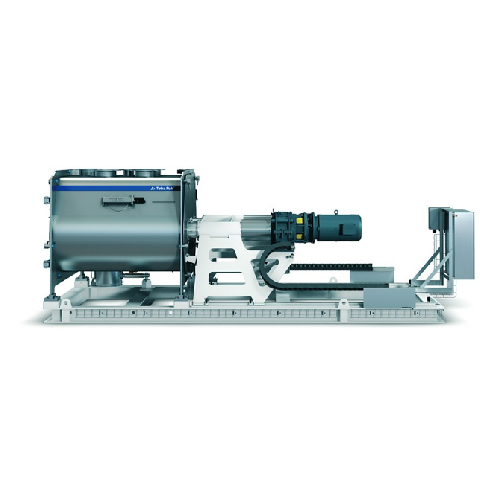

Batch mixer for dry and liquid ingredients

Achieve efficient blending of diverse ingredients with high shear mixing to str...

High-shear inline mixer for lump-free products

Achieve consistent texture and prevent clumping in liquid and powder blends...

Pre-mixer for dissolving powders fast

Quickly dissolve powders without lumps or “fisheyes,” ensuring a smooth a...

Process mixer for food production

Optimize your production line with a versatile and adaptable process mixer that offers se...

Multifunctional mixer for high volume batches

Efficiently handle complex mixing, emulsifying, and homogenizing tasks with ...

Blender for high viscous products

Tackle high-viscosity challenges with an advanced blending solution designed for efficien...

Customized oil storage tank for industrial use

Enhance production efficiency and ensure seamless integration with customiz...

Large insulated oil storage tank

Ensure optimal temperature control for sensitive liquids like oils, sauces, and creams with...

Cip dosing and water unit for industrial cleaning

Elevate your plant’s hygiene with this system, designed for seaml...

Conical buffer tank for hygienic dairy and food processing

Achieve efficient processing of high-viscosity products with ...

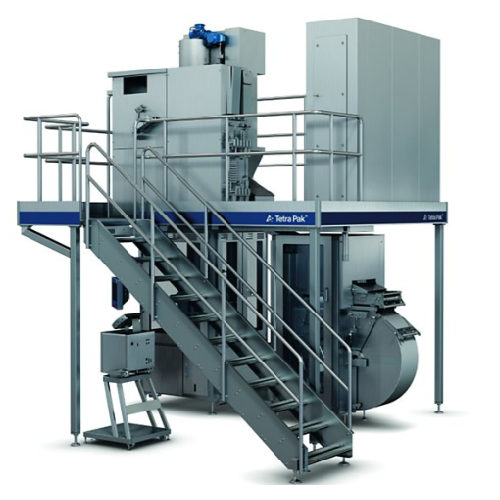

Protein drying system for dairy products

Optimize your dairy production with a customizable drying system designed for effi...

Large capacity horizontal motion conveyor for fragile products

Achieve gentle handling and minimize product damage with ...

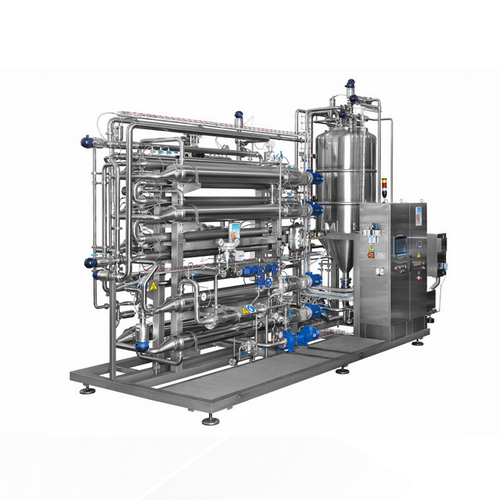

Htst pasteurization system for liquid foods

Ensure your liquid products are safe and long-lasting with high-temperature-sh...

Cip cleaning system for dairy industries

Ensure hygienic operation with this system, designed to maintain optimal cleanline...

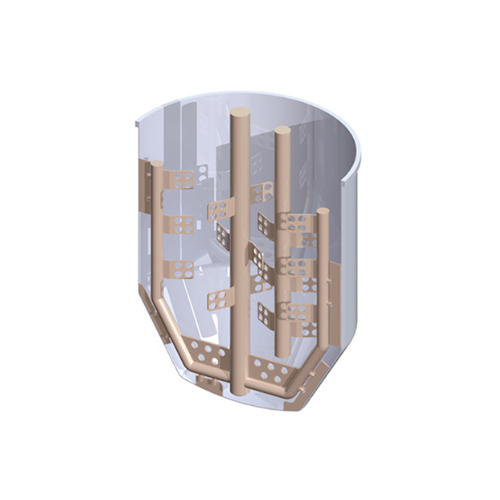

Agitators for mixing tanks

Optimize mixing operations with versatile agitators designed for various viscosities and fluid ty...

Homogenizer for high-pressure homogenization

Optimize your production with high-pressure homogenization, essential for ach...

High-pressure homogenizer for food and pharmaceuticals

Achieve unparalleled consistency and stability in emulsions and di...

Homogenizers for high-pressure applications

Achieve unparalleled product consistency and stability with precision-engineer...

Industrial homogenizer for food and pharmaceutical applications

Ensure product consistency and stability with high-press...

High-pressure homogenizers for dairy and food products

Achieve consistent texture and stability in your liquid products w...

High-pressure homogenizers for dairy and beverage industries

Achieve precise emulsion stability and consistent particle ...

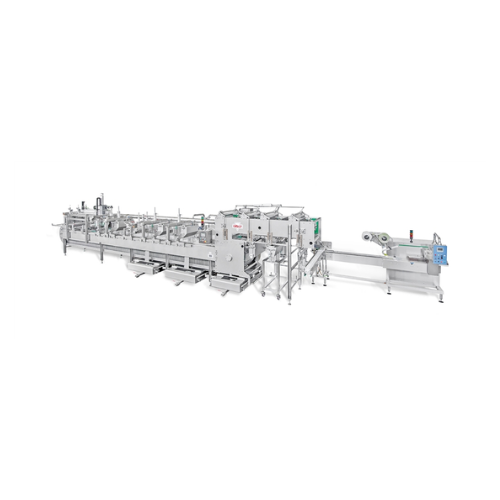

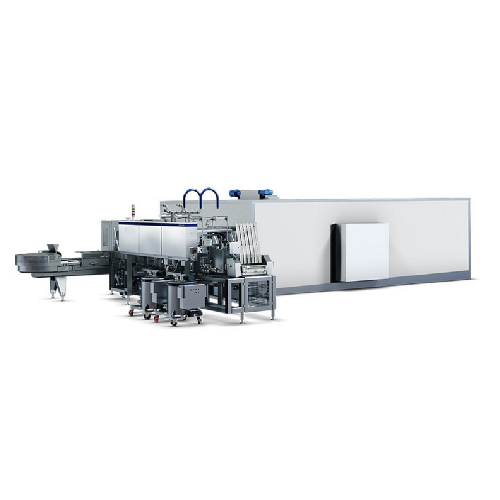

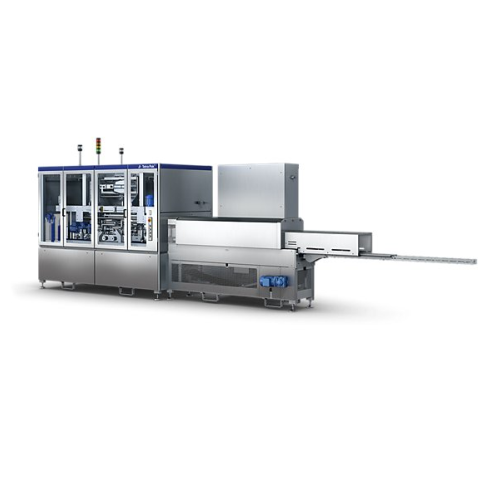

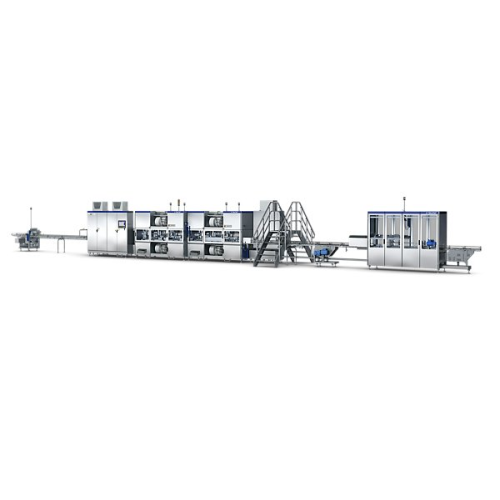

Automated in-line ice cream filling system

Enhance your ice cream production with precision filling, offering high-speed c...

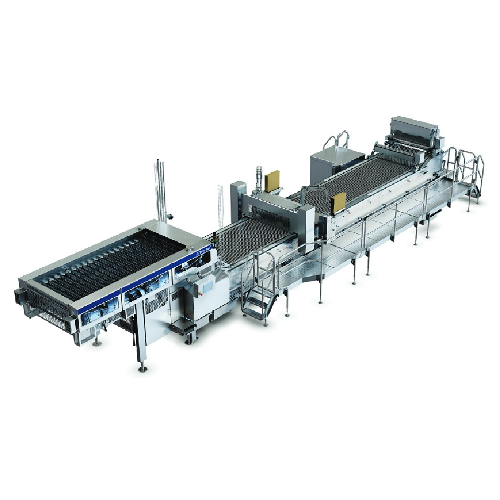

High capacity molding line for stick ice cream

Transform your frozen dessert production with an advanced molding line desi...

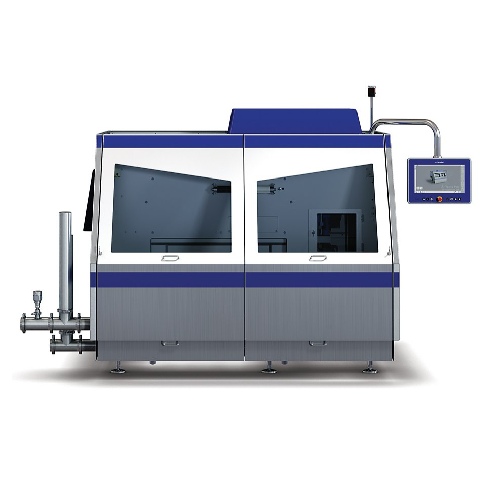

Continuous ice cream freezer

Enhance the consistency and texture of frozen desserts with this self-contained solution, strea...

Industrial freezer for ice cream production

Achieve consistent ice cream quality with precision freezing and texture contr...

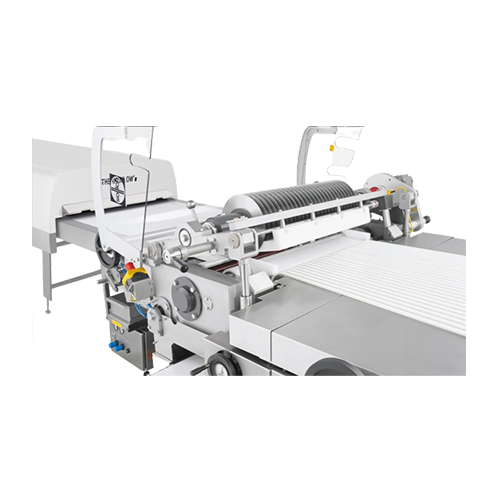

Multi-lane ice cream wrapping system

Optimize your production line with a high-speed, multi-lane wrapping system designed t...

High capacity molding line for ice cream sticks

Optimize your frozen dessert production with a high-capacity system that i...

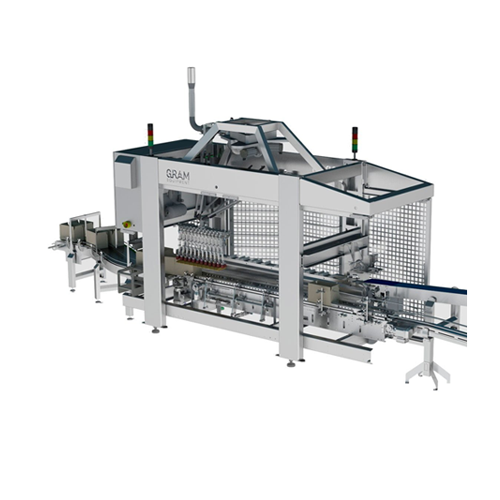

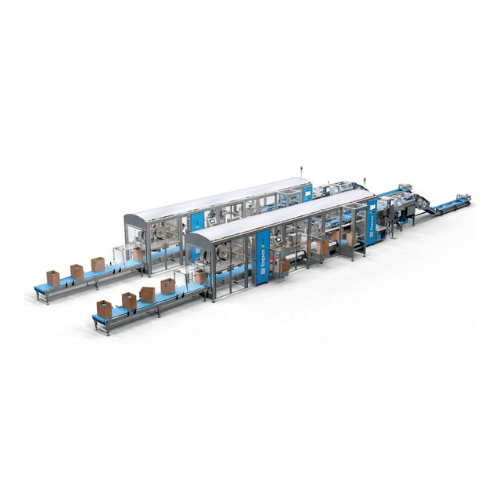

High-capacity ice cream cartonizing solution

Effortlessly handle complex ice cream production with a cartonizing solution ...

High-speed ice cream extrusion line

Achieve precise shapes and textures in your frozen treats with advanced extrusion solut...

Extruded ice cream with large inclusions

Streamline your ice cream production with an innovative extrusion solution, allowi...

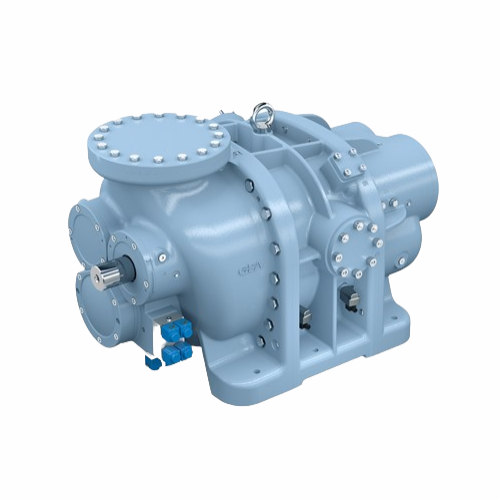

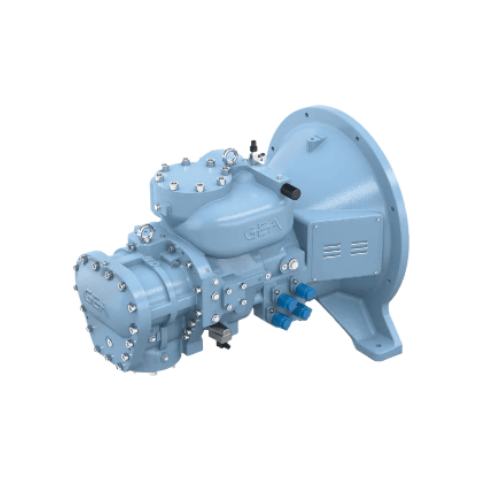

Industrial screw compressor for various refrigerants

Optimize your refrigeration systems with high-performance screw comp...

Scraped surface sterilizers for food industry products

Optimize your food processing line with high-efficiency sterilizat...

Aseptic filler for bag in box packaging

Optimize your bag-in-box packaging process with high-speed aseptic filling, ensurin...

Pasteurizer for dairy concentrates

Ensure optimal flavor and texture in dairy products with precise pasteurization that pro...

Fat glaze crystallization for sugar cones

Enhance the shelf life and quality of your ice cream cones by rapidly crystalliz...

Cryogenic tunnel freezer for continuous cooling

Achieve precise and efficient cryogenic freezing for continuous production...

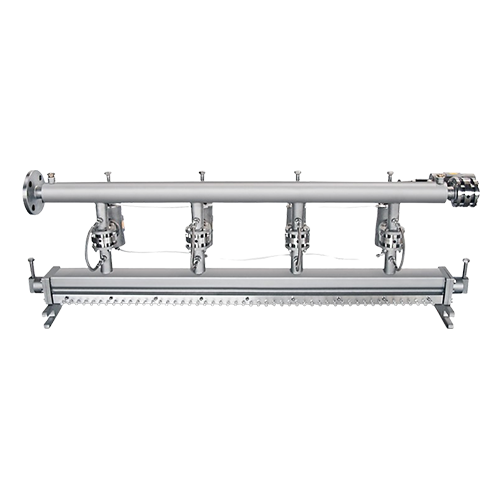

Nitrogen shower for instant ice cream topping hardening

Achieve rapid solidification of ice cream toppings with precision...

Cryogenic batch freezer for industrial processing

Achieve precise temperature control for sensitive materials with a cryo...

Inline high-shear mixer for powders and liquids

Achieve efficient mixing and homogenization in your production line with a...

High-capacity inline mixer for dairy and beverages production

Achieve a rapid and homogeneous mix in high-capacity produ...

Mixer for low to medium viscosity products

Optimize your mixing, dosing, and homogenization processes with a versatile mix...

Ultra-high shear mixer for emulsification and homogenization

Optimize your production with ultra-high shear mixing, acce...

Vacuum high shear mixer for medium to high viscosity products

Achieve flawless blending and air-free consistency in visc...

High-capacity manual mixer for industrial applications

Optimize your mixing process with a highly efficient, manually ope...

Bigbag discharge system for food, chemical, and pharmaceutical industries

Ensure precise and dust-free handling of bul...

Bigbag filling system for powder and bulk materials

Ensure precise and dust-free bigbag filling with this versatile syste...

Linear mould system for ice cream production

Optimize your ice cream line with modular flexibility, allowing seamless adap...

Rotary mould machine for ice cream production

Streamline your ice cream production with a rotary mould machine designed fo...

Piston pump continuous ice cream freezer

Optimize your ice cream production with a continuous freezing solution that seamle...

Industrial ice cream continuous freezer

Ensure precise temperature control and product consistency in ice cream manufacturi...

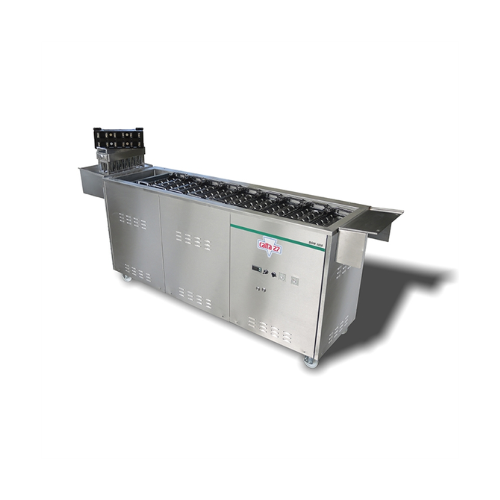

Hardening tank for water-ice lollies

Enhance your small-scale ice cream production with a versatile solution that allows yo...

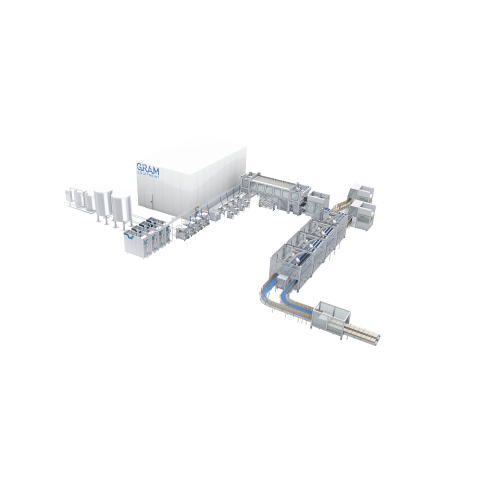

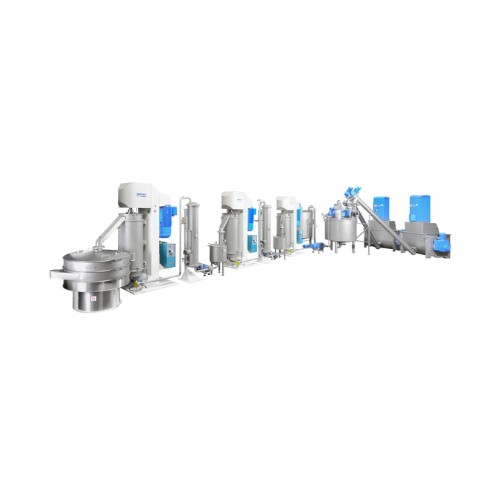

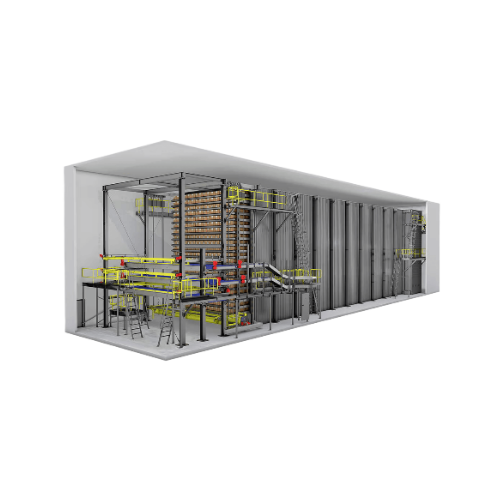

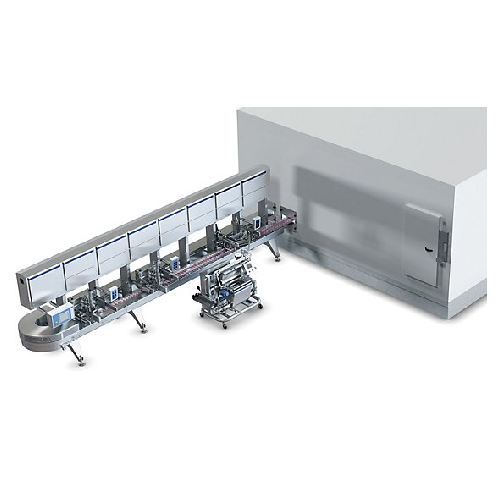

Pilot plant for ice cream production

Optimize your ice cream production with a flexible pilot plant that seamlessly integra...

Semi-automatic dosing table for ice cream cups and bulks

Ensure consistent and precise dosing for various ice cream produ...

Linear filling machines for ice cream production

Enhance your ice cream production with modular filling machines designed ...

Rotary filling solutions for ice cream cups and cones

Optimize your ice cream production with customizable rotary filling...

Lobe pump for industrial ice cream production with ammonia Nh3

Optimize your ice cream and dessert production with conti...

Lobe pump freezer for industrial ice cream production

Streamline your ice cream production with a semi-automatic lobe pum...

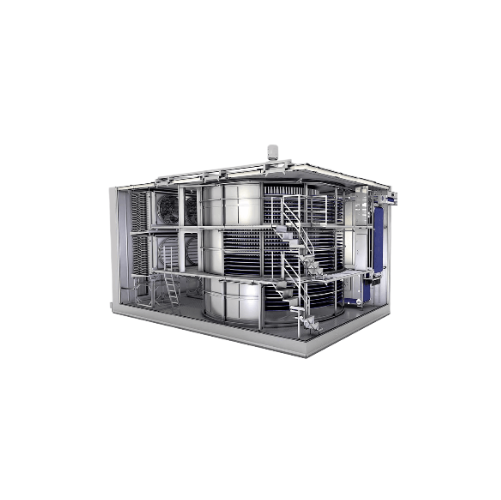

Batch mix preparation system for ice cream

Optimize your ice cream production with an efficient system designed for precis...

High-temperature short-time pasteurization system for dairy products

Optimize your dairy and ice cream production with ...

Fully automatic chocolate processing line

Accelerate your chocolate and confectionery production with this high-speed syst...

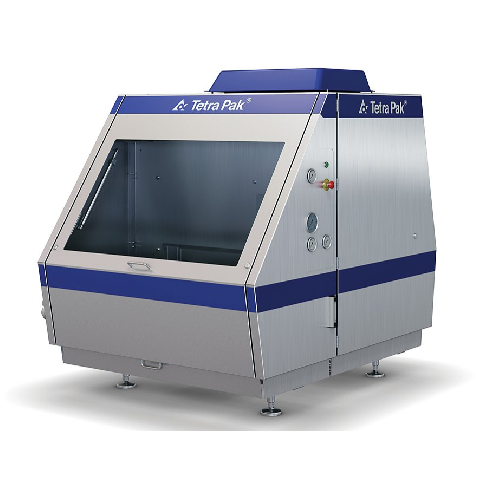

Laboratory batch chocolate processing unit

Achieve precision in developing chocolate recipes with a compact 3-in-1 unit th...

Chocolate processing unit for mixing, grinding, and conching

Optimize chocolate production with precise mixing, grinding...

Chocolate processing unit for mixing and grinding

Achieve precise mixing and conching efficiency for premium chocolate an...

Tube heat exchanger for chocolate and cocoa liquor

Achieve precise temperature control for chocolate and cocoa processing...

Wet conching system for chocolate production

Achieve optimal chocolate viscosity and flavor by effectively removing volati...

Laboratory conching solution for small batches of chocolate

Optimize your chocolate formulations with precise moisture a...

Ball mill refiner for fine cocoa grinding

Achieve high-precision grinding and refining of chocolates and cocoa with minima...

Automatic chocolate processing line

Transform your production by automating the complete chocolate-making process—from prec...

Ball mill refiner for cocoa liquor and chocolate production

Optimize your cocoa and chocolate refinement with precise gr...

Chocolate processing production line

Efficiently streamline your chocolate and compound production with a fully automatic s...

Wafer cone cooling table

Need consistent cooling and alignment of ice cream cones and wafers? This solution provides seamless...

Top load and side load case packer with vision guided robotics

Optimize packing efficiency and flexibility with a versat...

Vision guided robotics case packer

Maximize efficiency with vision-guided robotics for versatile case and tray loading, red...

Vertical packing pattern case packer

Optimize your packaging efficiency with this high-speed case packer designed for seaml...

Wrap around case packer for horizontal and vertical packing patterns

Optimize your palletizing and distribution with a ...

High-speed case packer for snack bags

Optimize your packaging efficiency with a compact solution designed for seamless vert...

Horizontal load carton erector for food production

Enhance your production line with precise carton erecting, loading, an...

Automatic case packer for frozen potato products

Efficiently pack frozen and delicate products with precision side-loading...

High-speed case packer for flexible bags

Streamline your packaging process with a solution designed for high-speed, error-f...

Horizontal case packing and tray loading

Enhance your packaging line efficiency with a highly adaptive system that seamless...

Vertical case packer for reusable and Rsc cases

Streamline your packaging line with versatile, high-speed case packing tha...

Tray erecting system for various tray styles

Effortlessly configure diverse tray styles with an efficient system designed ...

Automatic case forming and sealing solution

Streamline your end-of-line packaging with a solution that forms, folds, and s...

Milk clarifier for dairy industry

Enhance your dairy production with efficient milk and whey clarification, ensuring produc...

Plate heat exchanger sterilizer for food products

Ensure consistent product quality and microbiological stability in your...

Scraped surface evaporator for high-viscosity materials

Efficiently concentrate high-viscosity and hard-to-handle materia...

Gasketed plate heat exchangers for hygienic applications

Ensure optimal hygiene and thermal efficiency in your processing...

Gasketed plate heat exchanger for hygienic applications

Achieve precise temperature control for sensitive products with a...

Double seat valve for hygienic processing

Eliminate cross-contamination risks and enhance efficiency with a modular valve ...

Air-operated single-seat valves for food and beverage industries

Achieve precise flow control and elimination of downtim...

Sanitary static blender for food and beverage

Optimize your mixing process with low shear, energy-efficient blending desig...

Flavor vats for ice cream and food production

Maximize your product line versatility with customizable flavor vats, design...

Structure supported spiral freezer for food products

Optimize your high-speed production with a versatile spiral freezer ...

Industrial ejectors for reliable jet pump applications

Enhance process efficiency and reliability with industrial ejector...

Twin screw pump for viscous media

Streamline your production with a twin screw pump that effortlessly handles viscous media...

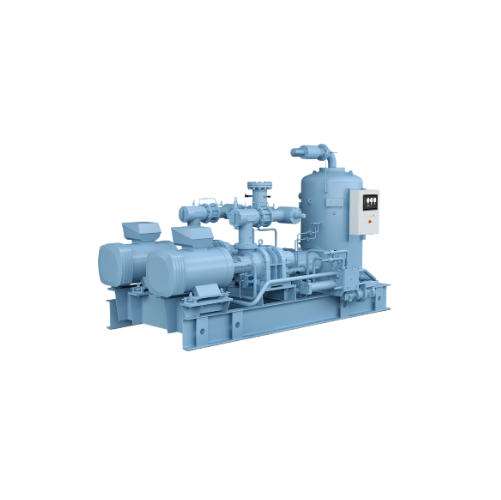

Packaged screw compressor for low temperature and high differential pressure

Optimize your refrigeration and cooling p...

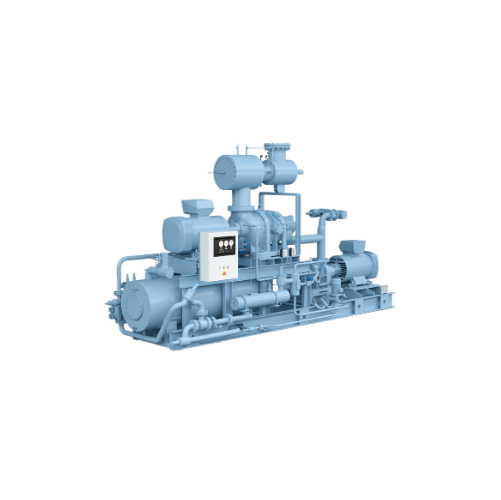

Industrial screw compressor systems for cooling applications

Maximize energy efficiency and system redundancy with paral...

Co2 cooling and Nh3 heating solution

Achieve precision in temperature control with cutting-edge high-pressure compressor sy...

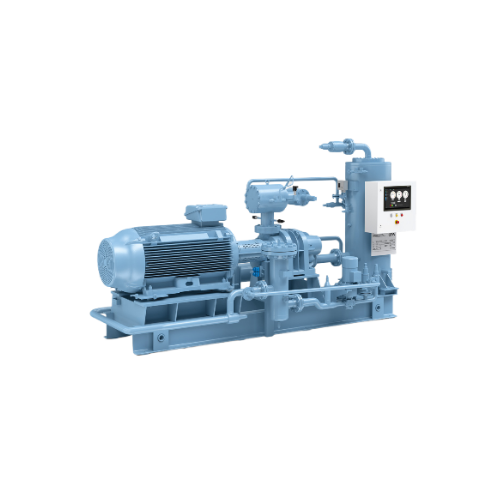

Compact refrigeration compressor package

Optimize your industrial refrigeration with a compact compressor package designed ...

Screw compressor package for efficient industrial cooling

Optimize your cooling processes with a flexible, space-saving ...

High shear mixer for low viscosity products

Achieve precise mixing and dispersion for diverse liquid applications with a h...

Pasteurizer system for dairy applications

Achieve optimal pasteurization with precise temperature control and energy-effic...

Microparticulation unit for whey protein processing

Enhance your dairy and food formulations with optimized whey protein ...

Industrial ammonia heat pump for efficient heating solutions

Need reliable and efficient heating capabilities while mini...

Very high pressure homogenizer compression block

Experience reliable performance at extreme pressures with a compression b...

High pressure industrial homogenizer

Enhance liquid formulations with precision and efficiency—our high-pressure homogenize...

Industrial homogenizer for small and medium production

Enhance product stability and extend shelf life with our high-pres...

Laboratory homogenizer for scaling nisox-valve benefits

Achieve reliable scaling from lab to production with this precise...

Customizable self-stacking solution for spiral freezers

Enhance your freezing process with a customizable self-stacking s...

Variable retention time carton freezer

Optimize your production line with a flexible freezing solution that handles multipl...

Customized spiral freezer solution for food industry

Designed to enhance your freezing efficiency, our spiral solution ha...

Frozen food products control system

Ensure optimal freezing precision with a system that continuously monitors product crys...

Dairy waste reduction with evaporator product recovery

Transform dairy processing by efficiently recovering valuable low ...

Combined heating and cooling solution

Optimize your production with a dual-purpose system designed to efficiently manage bo...

Industrial chiller with high part-load efficiency

Optimize your cooling processes with a versatile chiller designed for p...

Screw compressor chiller for industrial cooling applications

Optimize your cooling processes with our versatile screw co...

Industrial screw compressor package for ammonia refrigeration

Optimize energy use and ensure precise temperature control...

Compressors for Co₂ freezing applications

Optimize your cooling and heating processes with advanced reciprocating compress...

Industrial refrigeration reciprocating compressor

Optimize your refrigeration systems with advanced reciprocating compres...

High-efficiency ammonia chiller package for industrial applications

Optimize your cooling and refrigeration processes w...

Clean-in-place (cip) system for sanitation processes

Ensure thorough sanitation in your production line with a streamline...

Industrial buffer tank for temperature and texture control

Achieve precise temperature control and optimal texture with ...

Stainless steel centrifugal pump for liquid transfer

Optimize your food and dairy production with a reliable centrifugal ...

Turnkey stainless steel tanks

Optimize your liquid processing with versatile stainless steel tanks designed for efficient st...

Vessel dome fittings for tank protection

Ensure seamless production by preventing tank damage due to overpressure or vacuum...

Instrumentation calibration services for accurate measurements

Ensure precise control over your production variables by ...

Artisan ice cream processing equipment

Transform your ice cream production with high-efficiency equipment designed to strea...

Milk vending machines for dairy farmers

Streamline your dairy production with an efficient vending solution, providing farm...

Aseptic filler for fruit juice and dairy products

Ensure sterile, high-speed filling of liquids and creams with precision...

Aseptic filler for fruit juices and purees

Ensure product integrity and shelf stability with a versatile filler designed t...

Aseptic filler for various liquid and semi-liquid food products

For manufacturers focused on quality, this aseptic filli...

Aseptic filler for fruit juice and puree

Ensure optimal product safety and quality with this aseptic filler, designed to ha...

Aseptic filling solution for fruit juice and dairy products

Ensure product integrity and safety with this aseptic fillin...

High-speed vacuum blender for commercial use

Achieve optimal blending with cutting-edge vacuum technology, ensuring vibran...

Multi-lane ice cream wrapper

Achieve seamless wrapping of diverse ice cream products with high-speed precision and reduced m...

Bag tipping unit for Cip processes in powder handling

Ensure seamless powder handling and high hygiene standards in your ...

Manual bag tipping unit for powder handling

Ensure a contamination-free environment with a compact manual bag tipping unit...

Direct Uht treatment for liquid foods

Optimize aseptic production with advanced UHT technology to preserve nutritional valu...

Wrapping solution for ice cream products

Optimize your ice cream packaging with a high-speed multilane wrapper designed for...

Multilane wrapper for ice cream products

Achieve seamless ice cream wrapping with precision tension control and high-speed ...

Efficient dairy product separator

Achieve precise fat separation and enhance product quality while reducing energy consumpt...

Automatic milk standardization unit

Achieve precise control over milk’s fat, protein, and solids content, reducing cr...

Pasteurizer for dairy products

Enhance food safety and minimize operational costs with a cutting-edge pasteurizer designed f...

Air jet cleaning system for powder production

Eliminate water and chemical use while maximizing production efficiency with...

Lump breaker for dry powders and granulates

Optimize the consistency of your production line by efficiently breaking up lu...

Centrifugal sifter for food and pharmaceutical powders

Ensure consistent particle size and remove contaminants in high-sp...

Polynode technology for enhanced dairy separation

Achieve higher separation efficiency and capacity with innovative disc ...

Industrial powder mixer for food production

Enhance your production line with a high-speed batch mixer designed for precis...

Conical homogenizer for powder and granulated products

Achieve seamless homogenization of diverse powders and granulated ...

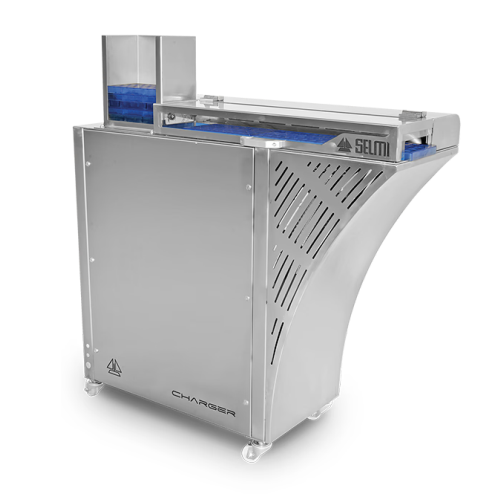

Ice cream mix preparation unit

Streamline your ice cream production with a low-energy, high-speed mix preparation unit that ...

High-capacity ice cream stick production line

Maximize production efficiency with a high-speed, continuous ice cream moldi...

Rotary moulder for ice cream production

Achieve high-speed, precise ice cream moulding with seamless integration into your ...

Ice cream rotary moulder 35 a2

Streamline your frozen treat production with high-capacity moulding that supports a variety o...

Batch dissolver for crystalline sugar and dextrose

Streamline your ingredient preparation with high-capacity batch dissol...

Ingredient dissolver for small batch processing

Optimize your mixing processes with a versatile dissolver designed for eff...

Drum unloader for liquid ingredients

Streamline the unloading of viscous liquid ingredients with advanced water injection t...

Plate heat exchanger for food products

Achieve precise temperature control in your processing line with this plate heat exc...

Tubular heat exchanger for food processing

Optimize energy consumption and ensure unparalleled food safety during heat tre...

Industrial homogenizer for liquid food applications

Achieve unparalleled product consistency and quality with high-speed ...

Homogenizer for high-capacity food processing

Achieve superior emulsification and suspension handling with this high-press...

Ingredient doser for ice cream with large inclusions

Achieve precise and uniform inclusion of fruits, nuts, and candies i...

Ingredient doser for ice cream products

Ensure precise and consistent addition of ingredients like fruit pieces or cookie d...

Centrifugal pump station for chocolate coating applications

Ensure precise temperature control and efficient chocolate c...

Autonomous ingredient dissolver for high-volume dry ingredient mixing

Efficiently mix multiple high volumes of dry ingr...

Ice cream sandwich production unit

Achieve consistent production of high-quality ice cream sandwiches with rapid, precise o...

Volumetric bottom filler for ice cream

Achieve precise distribution and inclusion integrity in moulded ice creams and froze...

Ice cream filling solution for cups and cones

Optimize your ice cream production with a compact filling solution capable o...

Lid unscrambler for unstackable lids in round containers

Streamline your packaging process with this lid unscrambler, eff...

Ice cream filler for consistent and efficient production

Achieve precision in ice cream production with a system that off...

Continuous freezer for ice cream production

Optimize your ice cream production with precision freezing, mixing, and air in...

Continuous freezer for ice cream processing

Achieve exceptional product uniformity and optimal texture with a continuous f...

Ice cream transfer and dipping solution

For ice cream manufacturers looking to maximize production efficiency, this solutio...

Ice cream dipping and transfer unit

Streamline your ice cream production with a multi-lane system designed for precise dipp...

Ice cream cone production system

Streamline your ice cream production and enhance product quality with a continuous system t...

Chocolate enrober for ice cream products

Optimize your ice cream and dessert production with precise, high-speed enrobing a...

Ice cream decoration depositing solution

Transform your ice cream line with precise decoration capabilities, enhancing prod...

Ice cream extrusion system

Optimize your ice cream production with a versatile system designed for efficient extrusion, shap...

Continuous evaporator for dairy products

Enhance your production efficiency with a fully automatic evaporator designed to m...

Aseptic dosing system for heat-sensitive ingredients

Enhance product quality and reduce ingredient waste by precisely inj...

Vibrating conveyor for short-distance powder transport

Achieve precise and hygienic powder conveying and dosing with this...

Aseptic tank with blending function for liquid food storage

Achieve seamless integration of aseptic buffering and in-lin...

Ibc rack for storing and discharging intermediate bulk containers

Optimize liquid handling in your production line with...

Liquid ingredient reception tank

Optimize your liquid processing with versatile tanks designed for efficient storage and han...

Continuous carbonator for beverage production

Optimize your beverage production with seamless continuous carbonation, ensu...

Pneumatic conveyor for fragile powders

Handle your delicate powders with care, ensuring minimal breakdown while achieving h...

In-line blender for beverage production

Enhance beverage production with a versatile solution that offers precise blending,...

Automated milk standardization unit

Achieve precise in-line standardization of milk components, ensuring optimal quality an...

Ultra-high temperature processor for premium liquid foods

Achieve superior product quality and flexibility with advanced...

High capacity milk separator with polynode technology

Achieve unprecedented milk skimming efficiency and reduced environm...

Energy-efficient dairy product separator

Achieve up to 40% energy savings in your dairy and beverage processing operations ...

High shear mixer for emulsification and powder dissolving

Achieve seamless mixing and emulsification for high and low vi...

High shear mixer for smooth or particulate food products

Achieve consistent quality in diverse food products with precise...

Industrial protein mixer for liquid food applications

Eliminate costly foam-related product losses in protein-enriched li...

Batch mixer for soft drinks ingredients

Effectively manage diverse ingredient formats with a high-performance mixing system...

Ice cream mix preparation solution

Achieve efficient, continuous ice cream and dairy product mixing with low-energy consump...

Dairy pasteurizer

Ensure product safety and quality while reducing energy consumption and operational costs with this advance...

Mid-range capacity homogenizer for dairy and beverage

For operations demanding consistent product quality and high uptime...

Industrial homogenizer for dairy and beverage applications

Enhance product quality and reduce operational costs with a h...

High-pressure homogenizer for dairy and beverage products

Achieve optimal product consistency and extend shelf life with...

Autonomous ingredient dissolver for high volume dry ingredient mixing

Streamline your production by seamlessly mixing d...

Batch dissolver for sugar or dextrose

Efficiently dissolve crystalline substances like sugar and dextrose with precision, e...

Ingredient dissolver for small batches

Efficiently dissolve water-soluble powders and concentrates up to 200 cP with precis...

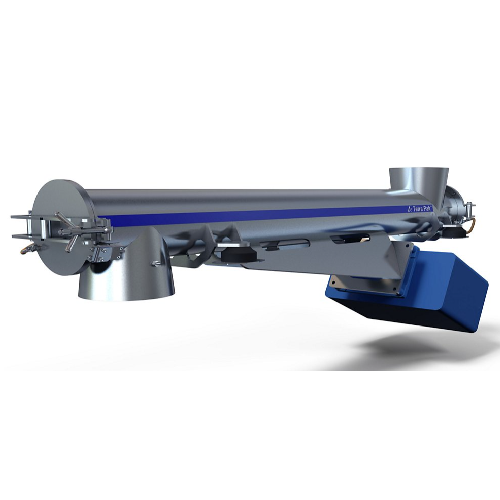

Contherm scraped-surface heat exchanger for viscous food products

Optimize your heating and cooling processes for stick...

Coiled heat exchanger for viscous and particulate products

Optimize heat treatment of viscous and particulate foods with...

Industrial plate heat exchanger for food processing

Ensure consistent product quality with precise temperature control an...

Tubular heat exchanger for food products

Achieve precise temperature control and energy efficiency with this innovative tub...

Storage tank for food liquid storage

Ensure seamless liquid product handling with precision-engineered storage tanks design...

Low-energy evaporation system for dairy products

Enhance product quality and lower energy costs with a cutting-edge evapor...

Plant-based beverage extraction system

Maximize yield and product quality in plant-based and dairy beverages with high-effi...

Aseptic tank for blending and buffering

Optimize your production line with a secure aseptic tank that ensures precise in-li...

Ingredient reception tank for liquid storage and processing

Ensure efficient storage and processing of liquid ingredient...

Liquid sugar storage tank

Ensure seamless liquid sugar management in your production line with advanced storage solutions de...

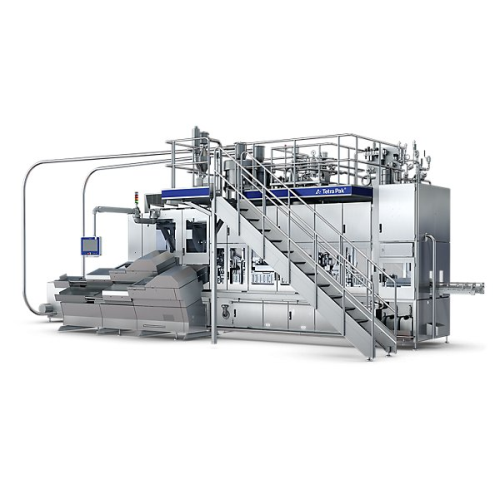

High-speed aseptic carton filling solution

Maximize production efficiency and meet growing demand with this high-output fi...

Filling system for gable top packages

Achieve precise, cost-effective filling with reduced energy consumption for chilled l...

Dual-line filler for tetra top packages

Maximize your production flexibility with a high-speed, dual-line filling solution ...

Filling machine for tetra rex® gable top cartons

Maximize efficiency and food safety in high-speed liquid filling with pre...

Filling system for gable top cartons chilled products

Achieve precise filling and reliable sealing for chilled beverages ...

Aseptic filling solution for tetra classic packaging

Experience efficient aseptic packaging with high-speed operation, of...

Filling system for tetra brik 100 slim packages

Optimize your chilled product packaging with a high-speed filling system d...

Aseptic carton filling system for tetra fino packaging

Elevate your production efficiency with a high-speed aseptic filli...

Filling system for tetra wedge aseptic packages

Optimize your production line with a reliable filling system designed to e...

Versatile filling system for aseptic packaging

Achieve seamless integration in high-speed aseptic packaging with this flex...

High-speed carton filler for aseptic packaging

Maximize production efficiency with this high-speed filling solution that e...

Carton filling system for tetra brik portion packs

Achieve high-capacity portion filling with innovative electron beam st...

Filling solution for tetra brik® packages

Optimize your filling and packaging process with a system that seamlessly switch...

Aseptic filling solution for liquid food packaging

Optimize liquid food production with advanced aseptic filling, ensurin...

Vertical package accumulator for food and beverage production

Ensure seamless flow and precise order tracking of package...

Cardboard packer for secondary packaging

Streamline your packaging process with a high-speed, automated cardboard packer th...

Shrink wrapping system for flex portion packages

Optimize your packaging line with a high-speed shrink wrapping system des...

High-speed shrink wrapping system

Enhance your packaging efficiency with a high-speed shrink wrapping system that ensures s...

Industrial tray shrink wrapper

Optimize your packaging line with rapid, resource-efficient shrink wrapping, accommodating di...

Straw applicator for tetra pak cartons

Ensure precise straw attachment and minimize production interruptions with a high-sp...

Straw applicator for tetra pak packages

Enhance your packaging efficiency with a high-speed solution that seamlessly attach...

Automated ingredient weigher for dairy production

Optimize your batching process with precise ingredient weight managemen...

Cleaning in place system for dairy processing plants

Streamline cleaning efficiency and ensure product quality in your da...

Continuous aerator for dairy products

Enhance the texture and flavor of dairy delights with precise gas infusion, transform...

Static mixer for homogeneous blending of ingredients in bakery and confectionary

Achieve consistent flavor and color i...

Conveyor belt freezer for industrial quick freezing

Ensure optimal preservation of food texture and nutrition with this a...

Commercial soft serve ice cream maker

Perfect for dessert establishments seeking versatility, this machine harmonizes mixin...

Commercial ice popsicle making solution

Optimize your frozen dessert production with a versatile machine capable of craftin...

Industrial peanut butter production line

Enhance your production line with this comprehensive peanut butter processing solu...

Commercial hard ice cream making solution

Achieve consistent high-volume production of gelato and hard serve ice cream wit...

Robotic pick and place platform for food packaging

Enhance your packaging efficiency and product quality with a scalable ...

Tubular Uht processing for dairy products

Experience efficient high-pressure thermal processing with tubular UHT technolog...

Self-priming centrifugal pump for entrained air handling

Effortlessly manage entrained air and foam in fluid processing w...

High pressure homogenization system for dairy and creams

Optimize your high-speed homogenization processes with precise c...

High pressure homogenizer for dairy and pharmaceutical industries

When uniform texture and stable emulsions are critica...

Uht system for milk and dairy products

Ensure superior product quality and extended shelf-life by utilizing rapid heat trea...

Tubular ultra high temperature processing system for dairy products

Optimize your dairy processing with precise thermal...

Ultra high temperature infusion plant for milk processing

Achieve extended shelf life and superior taste in dairy produc...

Combi ultra high temperature (uht) processing plant for dairy and beverages

Achieve precise heat treatment for diverse...

Ultra high temperature (uht) direct heating for infusion Esl plant

Achieve extended shelf life and superior flavor with...

Infusion Uht plant for dairy products

Achieve precise thermal treatment with minimal product alteration, enhancing quality ...

Infusion Uht system for dairy and plant-based beverages

Efficiently extend the shelf life of dairy and plant-based bevera...

Pilot plants for small-scale viscous product processing

Optimize your product development with pilot plants designed for ...

Process tanks for mixing, cooking, and cooling applications

Efficiently tackle viscous product challenges with advanced ...

Scraped surface heat exchanger for high viscosity products

When dealing with complex formulations, achieve efficient hea...

Buffer tanks for high viscosity fluids

Optimize your production line with buffer tanks designed to efficiently store, agita...

Crystallization and pin-working equipment for food processing

Optimize your food product quality with precise crystalliz...

Industrial dissolver for liquid-solid mixing applications

Optimize your production line with an industrial dissolver tha...

Continuous ice cream freezers

Achieve precise texture and consistency in frozen desserts with advanced ice cream freezers, o...

Horizontal mixers for industrial food production

Enhance your production efficiency by achieving uniform mixing of diverse...

Industrial fat melter for food and pharma applications

Optimize your production line with an advanced solution designed t...

Sprinkling system for decorating confectionery products

Enhance your confectionery line with precision sprinkling systems...

Bulk chocolate storage for confectionery production

Maximize space efficiency while maintaining product quality with our ...

Chocolate storage tanks for confectionery production

Optimize your confectionery production with state-of-the-art storage...

Sieving system for chocolate processing

Ensure product purity and consistency by seamlessly removing unwanted particles fro...

Decrystallization for tempered chocolate

Ensure your chocolate is perfectly smooth and free of fat crystals with an advance...

Confectionery rework tempering solution

Improve confectionery production efficiency by integrating a compact rework temperi...

Chocolate tempering solution for superior gloss and shelf life

Achieve consistent sheen and extend the shelf life of cho...

Precise metering system for dry confectionery ingredients

Achieve precise dosing of granular and dry ingredients like nu...

Automatic feeder for enrobing solid articles

Ensure seamless feeding for large-scale enrobing operations, enabling efficie...

Praline and bar product take-off system

Streamline your confectionery production with a versatile take-off system designed ...

Longitudinal slitting system for confectionery production

Achieve precise confectionery dimensions with our customizable...

Transverse cutting systems for confectionery production

Achieve precise cutting and slitting with high-speed transverse s...

Chocolate decoration systems for confectionery production

Enhance your confectionery production with precision chocolate...

Automated chocolate decoration system

Elevate your confectionery production with precision chocolate decoration, seamlessly...

Continuous bar production line for confectionery

Streamline your confectionery production with a seamless system for craft...

Chocolate shell molding system

Optimize your confectionery production with precision shell formation, enabling diverse and i...

Manifold system for producing weight-accurate ropes of chocolate or fruit masses

Achieve precise weight and shape in c...

Volume-precise moulding for chocolate and fat masses

Achieve precise and consistent moulding for chocolate and confection...

Continuous mixer for confectionery and bakery ingredients

Maximize production efficiency by seamlessly integrating mixin...

Retractable mass carriage enrober for chocolate coating

Improve production flexibility with a versatile enrober that allo...

Ice cream coating system for enrobing applications

Achieve seamless chocolate and nut coatings on ice cream bars and conf...

Enrobing system for full, half, and bottom coating of chocolates

Achieve precise and consistent chocolate coating with a...

Enrobing system for biscuits and baked goods

Achieve consistent and precise chocolate coatings with the versatility you ne...

Integrated tempering enrober for chocolate coatings

Enhance your chocolate production line with an integrated solution fo...

Industrial spreading systems for sticky products

Effortlessly manage the spread of sticky confectionery products with prec...

Cooling tunnel for center cooling in confectionery production

Efficiently manage center cooling in confectionery product...

Advanced cooling tunnel for confectionery production

Optimize your confectionery production with a cooling system that en...

High-precision biscuit sandwiching system

Efficiently align, fill, and sandwich high-speed biscuit rows while ensuring pre...

In-line metal detector for liquids & pastes

Ensure product safety by seamlessly integrating a metal detection system into ...

Cryogenic cooling tunnel for industrial freezing

Achieve precise temperature control and rapid freezing with a compact sol...

Milk pre-cooling systems for dairy farms

Optimize dairy production with advanced milk pre-cooling systems that significantl...

Cryogenic freezing tunnel for crust-freezing delicate foods

Enhance your production with rapid crust-freezing, expertly ...

Nuts paste refining mill

Transform nuts and dried fruits into fine pastes with precise particle control, ideal for creating p...

Simultaneous chocolate and ice cream dispenser

Unite the worlds of chocolate and ice cream with a machine capable of seaml...

Chocolate painting and spraying cabin with suction

Achieve impeccable decoration and coating of confectionery with a pain...

Automatic heated mould loader for chocolate production

Streamline your chocolate production with this heated mould loader...

Aseptic tank for liquid food storage

Store and maintain the sterility of low and high acid liquid foods while ensuring prod...

Continuous sugar dissolver for high brix solutions

Optimize your beverage production with a system that dissolves sugar u...

Pasteurization solution for food liquids

Extend the shelf-life of your liquid products while maintaining their quality with...

Custom syrup preparation systems

Optimize your beverage production with precision-engineered syrup preparation systems desig...

Uht sterilization solution for liquid food products

Enhance your liquid food processing with reliable UHT sterilization, ...

Industrial solutions for beverage mixing and carbonation

Optimize your beverage production with precise mixing and carbon...

Washdown Cartoner For Frozen Foods

When packing frozen foods into cartons, your packaging system should be cleaned by wash-...

Batch cooker for fruit puree

The fruit pulp is used in many different bakery products, especially as a filling. Since fruit ...

Concentrator for fruit puree preparation

Fruit puree is often an ingredient of various fruit-flavored yogurts, which someti...

Chocolate decorator for extruded ice-cream

It is not uncommon for ice-cream decorator units to become faulty and produce a...

High pressure electric laboratory homogenizer

It’s vital that small units for experimentation can scale up with 100% accur...

High pressure pilot homogenizer

Biotech and pharmaceutical development programs often require a mixing method that achieves ...

High pressure industrial homogenizer

For any industrial pharmaceutical process that relies on high pressure homogenization ...

Pilot high pressure homogenizer

For maximum value, a high-pressure homogenizer that’s suitable for both laboratory and pilot...

High pressure air powered laboratory homogenizer

Offering lab-scale to small pharmaceutical production scale output for in...

Stand-alone ultrasonic food cutting machine

For some foods such as cake, pizza, sandwiches or ice cream, the end product i...

Ice coating machine

Make consistent use of this high-quality, finish coat with your covered product. This is a coating machin...

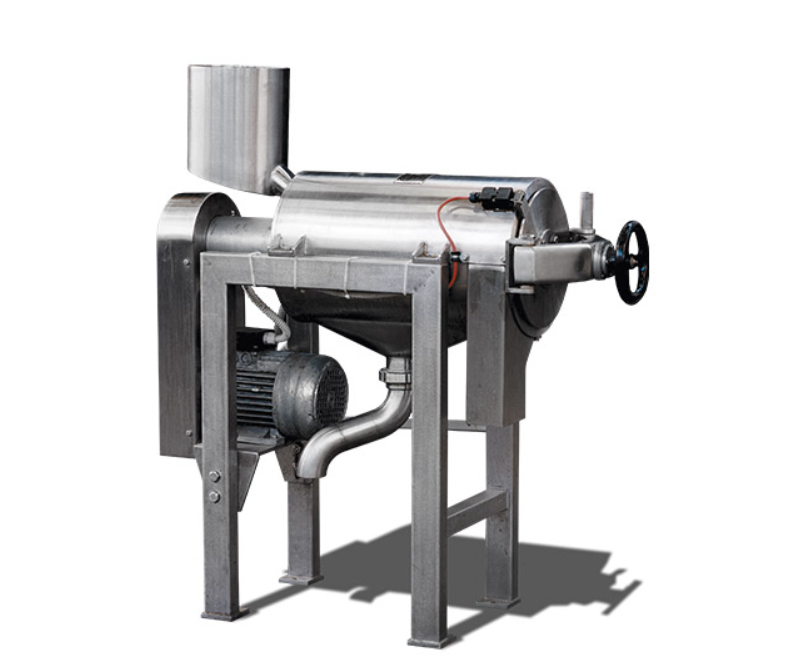

Fruit pulping machine

When making fruit pulp, a pulping machine helps you remove seeds, stems, and skins from your fruit. How...

Compact enrober

Cost-effective enrober for medium productions.