Industrial powder mixer for food production

Enhance your production line with a high-speed batch mixer designed for precise and gentle blending of various powders, ensuring consistent quality while reducing downtime with the fastest cleaning technology in the industry.

Mixes and Blends Powder Ingredients Efficiently

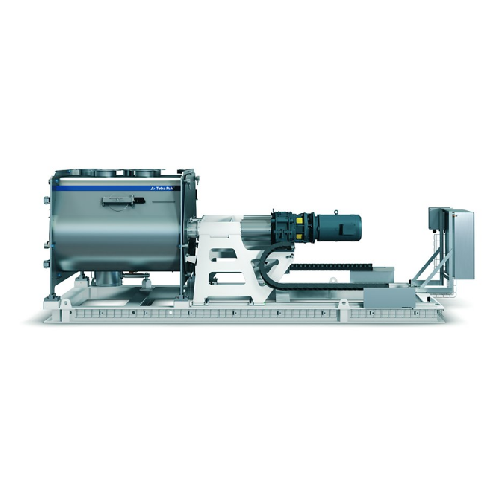

The Tetra Pak Powder Mixer B is a versatile batch paddle mixer designed by Tetra Pak for precise and gentle mixing of various powder ingredients, catering to food producers, dairy companies, and beverage manufacturers. This mixer stands out for its twin-paddle shaft technology, ensuring high homogeneity with above 99% accuracy. It efficiently handles up to ten batches per hour, making it ideal for mixing ingredients such as infant formula, protein powders, and seasoning blends.

Available in sizes accommodating batches from 300 to 4,000 liters, this mixer is suitable for applications ranging from chocolate milk powder and soy protein powder to cheese seasoning and plant-based milk powders. The Tetra Pak Powder Mixer B integrates seamlessly into production lines, offering a high level of automation with minimal operator intervention thanks to its PLC control.

A remarkable feature of this mixer is its commitment to hygiene. Designed in accordance with EHEDG guidelines and compliant with EC1935-2004 regulations, it incorporates features like fully welded tops and dust-tight door seals to minimize contamination risks. The internal surface roughness, under 0.8 microns, ensures efficient cleanability.

The robust design significantly reduces the need for maintenance, leveraging a unique power transmission system for long-term reliability. Additionally, the optional Tetra Pak Air Jet Cleaning system offers a waterless, rapid cleaning solution, further reducing downtime and operational costs.

Benefits

- Ensures high homogeneity with above 99% mixing accuracy, crucial for consistent product quality.

- Minimizes cleaning downtime with fast dry-cleaning technology, boosting overall production efficiency.

- Reduces maintenance costs with a reliable, robust design that offers long operational life.

- Enhances operator safety with compliance to European safety regulations and EHEDG guidelines.

- Offers flexible batch sizes, accommodating diverse production needs from small to large-scale outputs.

- Applications

- Food, Nectar, Still drinks, Cheese, Plant-based products, Milk powder, Plant-based powder, Ice cream, Infant formula powder, Whey, Juice, Dairy

- End products

- Vegan protein blend, Fruit-flavored drink mix, Energy drink powder, Ice cream stabilizer bases, Infant formula, Almond milk powder, Yogurt flavor mix, Chocolate milk powder, Cheese seasoning powder, Whey protein concentrate, Plant-based milk powder, Meal replacement shake mix, Soy protein powder

- Steps before

- Emulsification, Grinding, Weighing, Sifting

- Steps after

- Packing, Quality Control, Storage

- Input ingredients

- powder ingredients, all kinds of powders, food production powders

- Output ingredients

- homogeneous powder mixture, mixed powders

- Market info

- Tetra Pak is renowned for providing innovative packaging solutions, specializing in carton packaging for the food and beverage industry. It is esteemed for high-quality, sustainable, and efficient processing and packaging equipment on a global scale.

- Capacity

- 300-4, 000 litres

- Batch size

- 300-750 litres (B1200), 500-1, 300 litres (B2000), 850-2, 300 litres (B3500), 1, 550-4, 000 litres (B6000)

- Mixing Accuracy

- Above 99%

- Cleaning time

- 10 minutes (simple flushing), 90 minutes (thorough dry cleaning)

- Cycle time

- Up to 10 batches per hour

- Internal surface roughness

- Under 0.8 microns

- Noise level

- Low noise level

- Power transmission

- Gear motor and gear coupling

- Mixing Type

- Batch

- Cleaning Time

- 10–90 minutes

- Automation Level

- PLC

- Mixing Consistency

- Above 99%

- Failure Mode Effect Analysis

- Included

- Number of Batches per Hour

- Up to 10

- Inspection Access

- Fully Openable

- Paddle Technology

- Twin-paddle shafts

- Noise and Vibration Level

- Reduced

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine capacity

- 300-4000 litres

- Discharge method

- Fully openable and dismountable

- Inspection hatch

- Available

- Internal surface roughness

- Under 0.8 microns

- Control panel type

- Automatic control system available

- Design

- Twin-paddle shaft technology

- Material Handling

- Powder-to-powder mixing

- Operating principle

- Batch processing

- Batch size options

- 300-4000 litres

- Discharge valve design

- Fully dismountable

- Inspection hatch

- Quick assessment capability

- Paddle design

- Twin-paddle shaft technology