Mid-range capacity homogenizer for dairy and beverage

For operations demanding consistent product quality and high uptime, this homogenizer excels by ensuring uniformity in liquids like milk and juices while minimizing downtime through smart automation and modular design.

Ensures Consistent Homogenization and Recipe Management

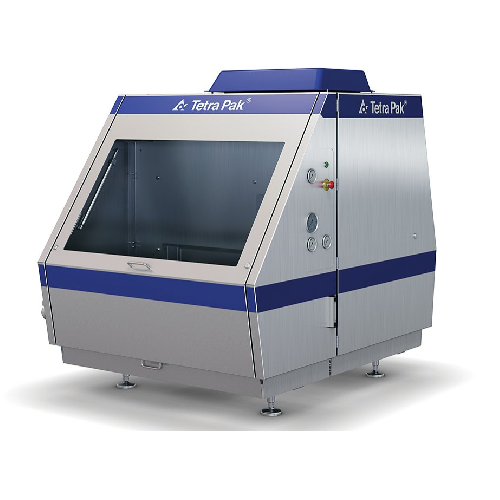

The Tetra Pak® Homogenizer 250 is an engineered solution specifically designed for liquid food processing. Its advanced automation capabilities set it apart, enabling precise control over homogenization and recipe management. Utilizing smart automation, it monitors critical parameters such as working and hydraulic pressure to ensure consistent product quality and operational integrity.

Ideal for a variety of applications, including pasteurized milk, ESL milk, UHT products, juices, and plant-based beverages, this homogenizer efficiently processes up to 13,700 liters per hour at 200 rpm. The fully removable modular design simplifies maintenance, reducing downtime by allowing quick replacement of hydraulic modules without halting production.

Material options include Outokumpu Circle Green® stainless steel, which offers a significant reduction in carbon emissions—up to 93% less than the industry average—while maintaining durability and reliability. The system integrates seamlessly into existing lines with PLC control and remote monitoring, supporting continuous operations with high uptime and minimized operational costs.

Engineered to handle high-pressure homogenization, the Tetra Pak® Homogenizer 250 meets rigorous industry standards, offering configuration flexibility to adapt to diverse production needs while ensuring low total cost of ownership over its lifecycle.

Benefits

- Minimizes operational costs through smart automation and recipe control.

- Ensures consistent high product quality by monitoring and adjusting critical processing parameters.

- Enhances production efficiency with high capacity and low rpm operation, reducing wear and maintenance needs.

- Reduces environmental impact with low carbon footprint stainless steel options.

- Facilitates quick maintenance and minimal downtime with a fully removable modular design.

- Applications

- Beverages, Long life milk, Cheese, Esl milk, Plant-based products, Pasteurized milk, Ice cream, Juices, Dairy products

- End products

- Flavored yoghurt, Fruit smoothies, Uht milk, Mozzarella, Long shelf-life milk, Plant-based creamers, Cheddar, Orange juice, Almond milk, Oat milk, Soy milk, Cream cheese, Lactose-free dairy beverages, Vanilla ice cream, Fruit nectar, Probiotic drinks, Chocolate milk, Whole milk

- Steps before

- Emulsification, Pre-mixing, Heat treatment, Pasteurization

- Steps after

- Storage, Packaging, Cooling, Quality control

- Input ingredients

- pasteurized milk, ESL milk, beverages, low acid products, high acid products

- Output ingredients

- homogenized milk, homogenized beverages, consistent NIZO value products

- Market info

- Tetra Pak is renowned for providing innovative packaging solutions, specializing in carton packaging for the food and beverage industry. It is esteemed for high-quality, sustainable, and efficient processing and packaging equipment on a global scale.

- Capacity

- 13, 700 l/h

- Speed

- 200 rpm

- Automation

- Smart automation with automatic process and recipe control

- Material Type

- Outokumpu Circle Green® stainless steel

- CO₂ Reduction

- 300kg to 2500kg per machine

- Cooling System

- Fully removable for easy maintenance

- Automation level

- Smart automation with warnings and conclusions

- Homogenizing capacity

- Up to 13, 700 l/h

- Batch vs. continuous operation

- Continuous

- Uptime

- Highest uptime in the medium segment

- Changeover time

- Fast service with removable modular design

- CIP/SIP

- CIP compatible

- Cooling System

- Removable for easy maintenance

- Energy efficiency

- Low operational costs

- Product type flexibility

- Low and high acid products

- Application range

- Pasteurized milk, ESL milk, beverages

- Machine Footprint

- Compact design

- Control panel type

- Smart Automation System

- Modular design

- Fully removable design

- Material Construction

- Outokumpu Circle Green® Stainless Steel

- Capacity

- Up to 13, 700 l/h

- Drive System

- Low RPM Drive Unit

- Control panel type

- Smart automation system

- Integration possibilities

- Recipe control, automation

- Modular design

- Fully removable

- Material option

- Outokumpu Circle Green stainless steel

- Replacement feature

- Removable hydraulic module