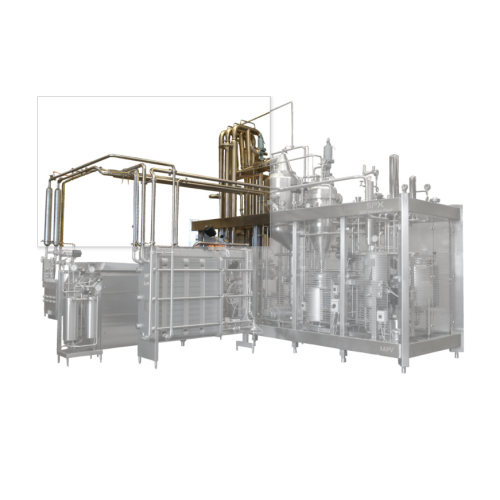

Ultra high temperature (uht) direct heating for infusion Esl plant

Achieve extended shelf life and superior flavor with fast, gentle infusion, ensuring your dairy and beverage products maintain optimal freshness while reducing bacteria spore levels.

Processes and Pasteurizes Liquid Products Efficiently

The Infusion ESL Plant with Ultra High Temperature Direct Heating from SPX FLOW offers a cutting-edge solution for the dairy and beverage processing industries. Utilizing direct heating technology, this system efficiently pasteurizes and extends the shelf life of liquid products by rapidly increasing temperatures to 1112°F (600°C) per second, with precise control ensuring minimal chemical change and optimal flavor retention.

Ideal for applications ranging from whole and skim milk to flavored creamers and milkshakes, the plant supports continuous, high-speed operations, significantly reducing bacterial spore presence while preserving the nutritional and sensory qualities of your products. The pre-assembled unit is designed with operator-friendly features, enabling ease of integration into existing production lines and reducing industrial downtime between Clean-In-Place (CIP) cycles.

With compliance options designed according to ASME, PMO, and 3-A standards, and the flexibility to handle various dairy and plant-based liquids, this equipment is engineered for durability and efficiency. Its pre-testing at the factory level further assures seamless startup and operation. Optional configurations and customizations are available to meet specific processing needs and plant environments.

Benefits

- Extends product shelf life up to 45 days, minimizing waste and enhancing distribution flexibility.

- Ensures superior product quality with rapid, gentle heating that maintains natural flavor profiles.

- Reduces operational costs with low fouling rates and long intervals between maintenance cycles.

- Enhances process efficiency by achieving high bacterial spore reduction in a continuous operation.

- Speeds up production with a high-speed, operator-friendly design that easily integrates into existing lines.

- Applications

- Cream, Beverage processing, Milk, Milk shake, Dairy processing, Ice cream mix, Food processing, Coffee cream, Flavored milk

- End products

- Fruit smoothies, Hazelnut coffee creamer, Skim milk, Soft serve ice cream mix, Cheese sauce, Vanilla milkshake, Yogurt drinks, Whipping cream, Chocolate milk, Whole milk

- Steps before

- Filtration, Homogenization, Mixing, Blending

- Steps after

- Packing, Cooling, Storage

- Input ingredients

- milk, flavored milk, coffee cream, cream, ice cream mix, milk shake

- Output ingredients

- extended shelf life milk, extended shelf life flavored milk, extended shelf life coffee cream, extended shelf life cream, extended shelf life ice cream mix, extended shelf life milk shake

- Market info

- SPX Flow is renowned for its expertise in manufacturing industrial ETO equipment, specializing in fluid handling and processing solutions. They are recognized for innovation, reliability, and providing efficient solutions across diverse industries, including food, beverage, and industrial markets.

- Pasteurization Time

- 0.5 seconds

- Heating Speed

- 1112°F (600°C)/sec

- Holding Time

- Accurate holding time

- Bacteria Spore Kill Rate

- High

- Shelf Life

- Up to 45 days

- Operating Conditions

- Long time between CIP

- Working mechanism

- Infusion UHT Direct Heating

- Integrated steps

- Pasteurization

- CIP/SIP

- Pre-assembled and factory tested

- Batch vs. continuous operation

- Inline Continuous

- Changeover time

- Long operating time between CIP

- Automation level

- Operator-friendly

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Flexible product variety

- Milk, Flavored milk, Coffee cream, Cream, Ice cream mix, Milk shake