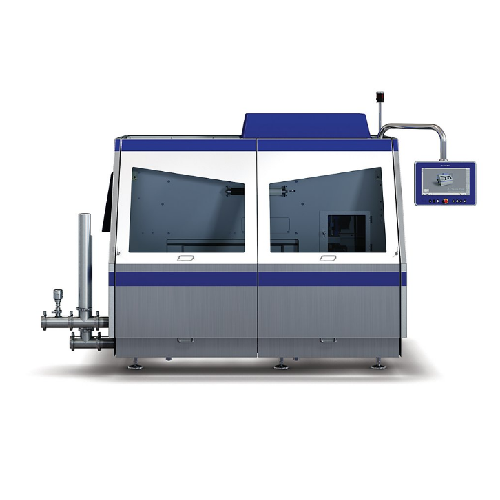

Homogenizer for high-capacity food processing

Achieve superior emulsification and suspension handling with this high-pressure homogenizer—ideal for enhancing product stability and texture across a range of demanding applications, from dairy to plant-based beverages.

Homogenizes High-Volume Dairy and Beverage Products

The Tetra Pak® Homogenizer 500 is a high-capacity solution designed for food and beverage manufacturers aiming to streamline homogenization processes. It employs high-pressure technology to ensure optimal emulsification and suspension handling, enhancing product consistency and quality. With a capacity of 63,600 liters per hour, it effectively homogenizes a variety of products, including milk, plant-based drinks, juices, and sauces. Offering the lowest total cost of ownership, it’s equipped with a PLC system for seamless automation and integration within existing production lines. The machine features a serial cooling system, reducing water and steam consumption by up to 80% compared to conventional designs. Constructed with options like Outokumpu Circle Green® stainless steel, it minimizes environmental impact, ensuring durability and reliability for continuous operations. Configurable for specific processing needs, the homogenizer supports CIP (Clean-in-Place) to maintain hygiene and efficiency, making it ideal for diverse applications in dairy, beverage, and condiment manufacturing.

Benefits

- Reduces operational costs with the lowest total cost of ownership.

- Minimizes environmental impact using a high-efficiency serial cooling system, saving up to 80% on water and steam.

- Ensures consistent product quality with superior homogenizing efficiency for optimal texture and stability.

- Increases line efficiency with long service intervals and low maintenance requirements.

- Enhances sustainability with options for materials that cut CO₂ emissions by up to 93%.

- Applications

- Cream, Sauces, Cheese, Tomato products, Ice cream mix, Dairy, Food, Uht milk, Ice cream, Rngs beverages, Liquid egg, Fruit juices, Still drinks, Purées, Gravies, Plant-based products, Powder, Condensed milk, Concentrates, Juice, Nectar, Yoghurt, Ketchups, Pasteurized milk, Dressings, Mayonnaise

- End products

- Fruit purée for baby food, Tomato paste, Liquid egg whites, Coconut cream, Pasteurized whole milk, Oat-based drink, Greek yoghurt, Almond milk, Rice milk, Uht skimmed milk, Soy milk powder, Strawberry fruit juice, Tomato sauce, Whipping cream, Brown gravy, Probiotic yoghurt, Salad dressings, Vanilla ice cream mix, Evaporated milk, Organic ketchup, Condensed sweetened milk, Vegan mayonnaise, Raspberry concentrate, Chocolate-flavored milk

- Steps before

- Emulsification, Suspension preparation, Milk pasteurization, UHT processing, Cream production, Juice extraction, Condensation, Preparation of mix, Sauce preparation

- Steps after

- Aseptic filling, Packing, Spray drying, Bottling, Canning, Cooling, Storage, Distribution

- Input ingredients

- pasteurized milk, UHT milk, cream, yoghurt, condensed milk, ice cream mix, fruit juices, RNGS (rice, nut, grain, soy) beverages, concentrates, purées, tomato products, dressings, ketchups, liquid egg, mayonnaise, sauces, gravies

- Output ingredients

- homogenized pasteurized milk, homogenized UHT milk, homogenized cream, homogenized yoghurt, homogenized condensed milk, homogenized ice cream mix, homogenized fruit juices, homogenized RNGS beverages, homogenized concentrates, homogenized purées, homogenized tomato products, homogenized dressings, homogenized ketchups, homogenized liquid egg, homogenized mayonnaise, homogenized sauces, homogenized gravies

- Market info

- Tetra Pak is renowned for providing innovative packaging solutions, specializing in carton packaging for the food and beverage industry. It is esteemed for high-quality, sustainable, and efficient processing and packaging equipment on a global scale.

- Capacity

- 63, 600 litres/hour

- Homogenizing Efficiency

- Highest in industry with HD EnergyIQ

- Utility Consumption

- Lowest in industry

- Pressure

- Variable

- Service Interval

- Up to 40% longer

- Cooling System

- Serial cooling

- Material

- Outokumpu Circle Green® stainless steel

- Water Consumption

- 70% less steam, 80% less water

- Electricity Usage

- 3 kWh per 1000 litres

- Cooling Water Consumption

- 12.6 litres per 1000 litres of product

- Outlet Temperature

- Minimum 110°C

- High Pressure Handling

- Handles high-pressure homogenization

- Product Viscosity Range

- High and low viscous products

- Product Type Variability

- Aseptic and non-aseptic products

- Pump Capability

- Available as high-pressure pump

- Homogenizing Efficiency

- Highest efficiency with HD EnergyIQ

- Utility Consumption

- Lowest utility consumption

- Service Access

- Easy access for faster service

- Service Interval

- Long service intervals

- Water Consumption

- Low water consumption

- Steam Consumption

- Low steam consumption

- Energy Efficiency

- Optimal pressure for energy savings

- Aseptic Barrier Temperature

- Minimum 110 °C

- Cooling Water System

- Serial system

- Cooling Water Reuse

- 80% re-circulated

- Uptime

- High uptime design

- Running Hours Extension

- Optional damper module

- Abrasion resistance

- High

- Corrosive resistance (e.g. acids)

- Stainless steel

- Cleanability

- SIP/CIP

- Biological compatibility

- Food-grade

- Density/particle size

- Compatible with varying sizes

- Control panel type

- Integrated with smart automation

- Safety and sealing

- Aseptic barrier with high-temperature safety features

- Material choice

- Outokumpu Circle Green® stainless steel

- Control panel type

- Smart automation

- Integration

- Feeding spray dryer, aseptic/ non-aseptic operation

- Pressure and capacity

- Variable

- Serial cooling system

- Minimizes water and steam consumption