Yogurt Making Equipment

Find innovative production technology for making yogurt and connect directly with world-leading specialists

Yogurt makers start with raw milk from animals like cows and goats and produce yogurt by standardizing milk, reducing fat content and increasing total solids before pasteurizing to remove harmful bacteria. After pasteurization, the milk undergoes homogenization to make it smoother and more consistent. The milk then receives yogurt cultures, and the product undergoes a fermentation process. Finally, you can cool and refrigerate the yogurt and prepare it for packing.

Select your yogurt process

Tell us about your production challenge

The “culture” that turns milk into yogurt

The key ingredient for producing high quality yogurt is the starter culture that goes into the milk. These cultures or bacteria ferment and produce lactic acid, which acts on the milk protein to give yogurt its texture and taste. Adding the necessary bacteria in a controlled manner is important since the level of acidity during the fermentation process affects the final product. The incubation process takes place inside a sealed hygienic stainless-steel cylindrical vessel equipped with devices that measure and control the temperature, pressure, and pH level. The acid level of the product is monitored until it reaches a pH level of about 4.4 to 4.5. Then, the yogurt is cooled to end the fermentation process.

How do you like your yogurts served? The different yogurt making equipment that makes the difference

Yogurts come in different types due to differences in yogurt processing. The common processes start from the standardization, pasteurization, homogenization, and fermentation of fresh milk. After that, you can opt for different techniques and materials depending on the type of yogurt you want.

Set, stirred, liquid…

Set yogurt is the firmest type with a jelly-like texture. Its fermentation occurs directly in the selling container, which makes it firm. Stirred, one of the most common yogurts in the market, has milk fermentation in a single container. You need to cool it to stop the fermentation process and then include fruits and flavoring. Finally, you put in individual containers, making it less firm than set yogurts. Liquid yogurt, the drinkable type, has a similar process to stirred yogurts, but with more agitation to break up the coagulum. One way to do that is to let the yogurt undergo a homogenization process after initial cooling from fermentation.

…frozen...

Frozen yogurt started out as a mixture of milk, cream, sugar, and other ingredients based on a particular recipe. The liquid ingredients are mixed into a vat and heated. After mixing the ingredients, pasteurizing, homogenizing and stirring the yogurt culture in the mixture, you must cool it down slowly. Then, store it in aging tanks inside coolers for about 4 hours. Add other flavorings and pump the mixture to the freezer, where it will agitate until it freezes and achieves the desired overrun. Next, pack the mixture and place it in freezers to continue the freezing process rapidly to form tiny and smooth ice crystals, giving the frozen yogurt its ice cream texture.

...and Greek yogurt

Greek or strained yogurt undergoes a similar process to stirred yogurts. The difference is that you must remove the liquid whey after stirring by heating and straining through filtration or centrifuge, which results in a thick and concentrated product. As a result, the product has a much higher protein content. The name “Greek yogurt” got popular in the United Kingdom in the 1980s, when strained yogurt was imported to the country by a Greek company. That was the moment when “Greek yogurt” became the same as strained yogurt in English.

Available in a wide variety of flavors and fruits

Yogurts with different flavors and aromas have become quite popular. The most common variety is fruit-flavored yogurts, to which you add flavorings such as puree or whole fruits in syrup before filling the containers with yogurts. For stirred yogurts, you add the fruit after cooling the yogurt. For non-fruit flavors, you can add these to the yogurts before dispensing them into containers for packaging.

Filling it up and sealed for freshness

Yogurts, like most dairy products, require aseptic filling and sealing. In this case, you sterilize the full yogurt production line including equipment, containers, and packaging material using steam, heat, and other treatments to avoid contamination. Use precise filling machines to fill the containers to prevent drip or spillage. After filling the containers, they are sealed with hygienic lids before being sent for packing. Aside from precise filling and sealing of the containers, conveying these products after filling requires stable handling to minimize the breaking down of physical properties, especially for set yogurts.

Processing steps involved in yogurt making

Which yogurt technology do you need?

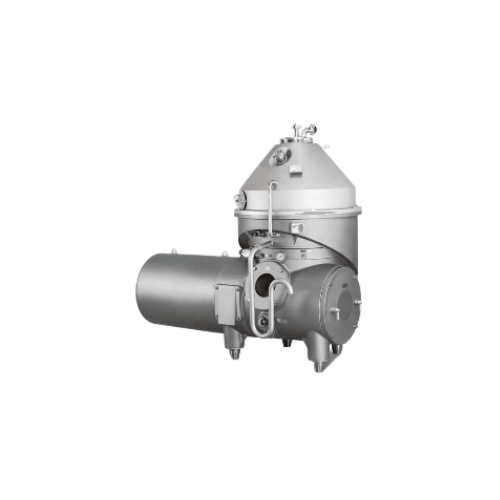

Nozzle separators for strained yoghurt production

Maximize yield and ensure consistency in your dairy production by integ...

Fermentation tank for yoghurt and fermented dairy products

Optimize your dairy and plant-based drink production with eff...

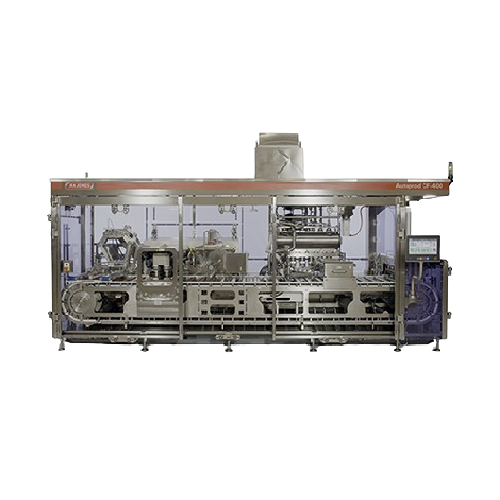

Cup filling and sealing system for dairy products

Optimize your production line with versatile cup filling and sealing ca...

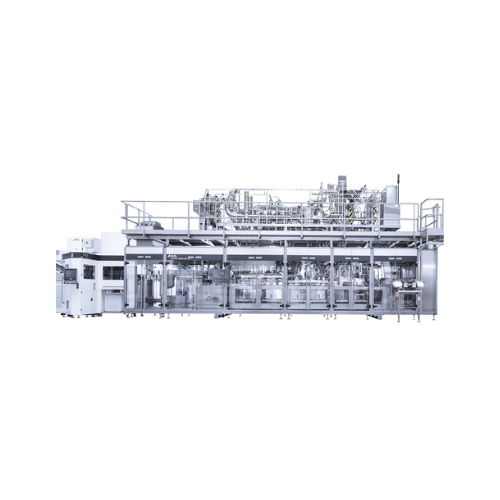

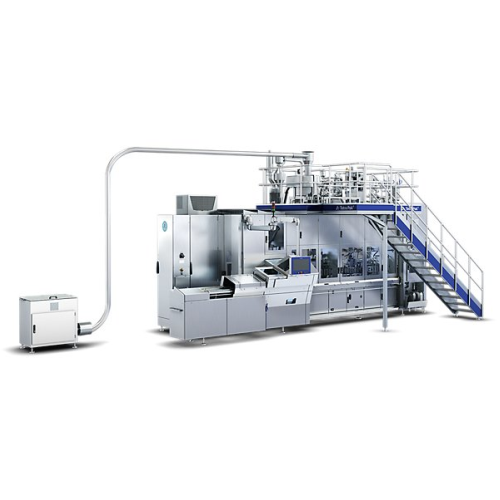

Industrial yogurt production line

Streamline your yogurt production with precise process control to ensure consistent quali...

Direct steam injection Uht pilot system

Elevate your production capabilities with a sanitary UHT pilot system designed for ...

Lab-scale water bath blending vessel for product preparation

Ensure consistent flavor and quality across diverse small-s...

Lab-scale carbonation system for beverage filling

Streamline your beverage development with precision carbonation and ver...

Homogenizer for dairy products

Achieve precise texture and quality in dairy products with this versatile homogenizer, design...

Stainless steel tanks for dairy processing

Optimize your dairy processing with customizable stainless steel solutions for ...

Cylindrical buffer tank for processing lightly liquid products

Optimize production continuity with this cylindrical buff...

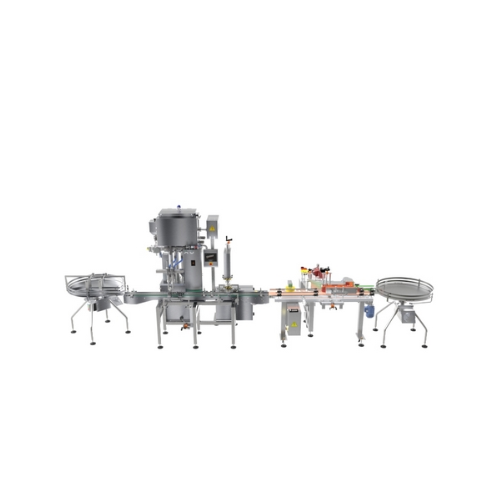

Medium capacity filling line for food and cosmetics

Streamline your production with a versatile filling line that seamles...

Aseptic linear filler for sensitive beverages

Experience unparalleled versatility and efficient aseptic filling with advan...

Counter-rotating agitator for high viscosity products

Achieve seamless heat transfer and precise mixing with a counter-ro...

Rotary filling and sealing for liquid to pasty products

Boost production efficiency with a flexible rotary solution that ...

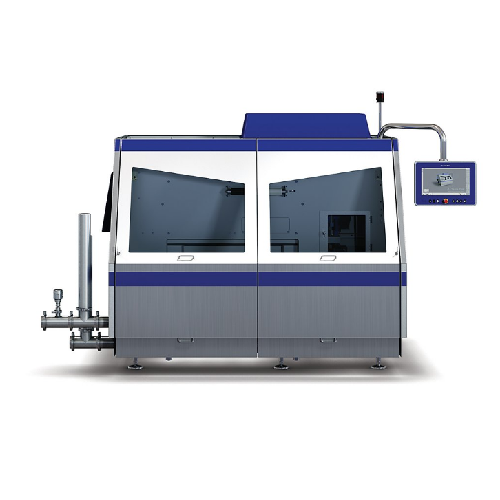

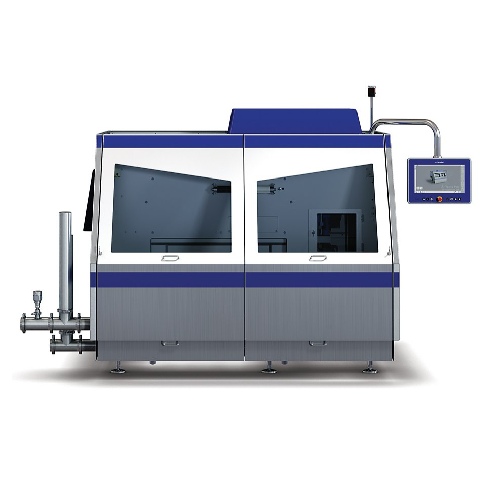

Filling and sealing system for pre-formed cups

Experience seamless integration of hygienic filling and sealing with adapta...

Filling and sealing pre-formed cups solution

Ensure ultra-clean and aseptic processing for pre-formed cups with a fully en...

Filling and sealing solution for pre-formed cups

Optimize your liquid and solid product filling with a continuous-motion s...

Form fill and seal solution for liquid and pasty products

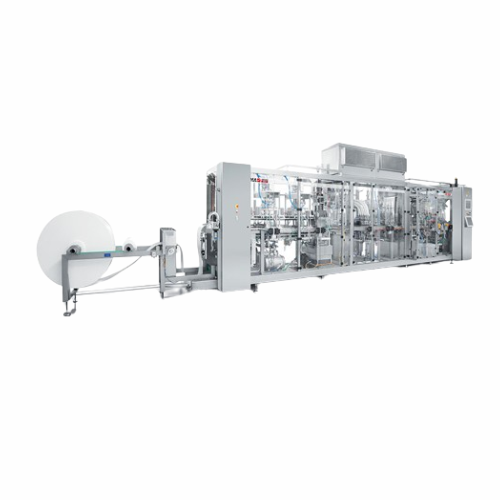

Enhance your production efficiency with high-speed forming, fi...

Flexible filling and sealing system for pre-formed cups

Achieve precise portioning and consistent quality in your product...

Filling and sealing system for yoghurts and desserts

Efficiently fill and seal a variety of dairy and dessert products wh...

Rotary filler and sealer for dairy products

Optimize your filling and sealing needs with a compact solution designed for c...

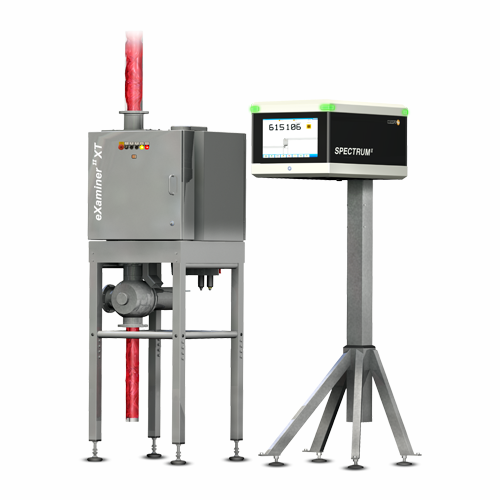

Pipeline inspection for liquid and paste-like products

Ensure your liquid and paste-like products are free from foreign o...

Pipeline metal detection for pumpable products

Ensure safety and quality by detecting and rejecting metal contaminants in ...

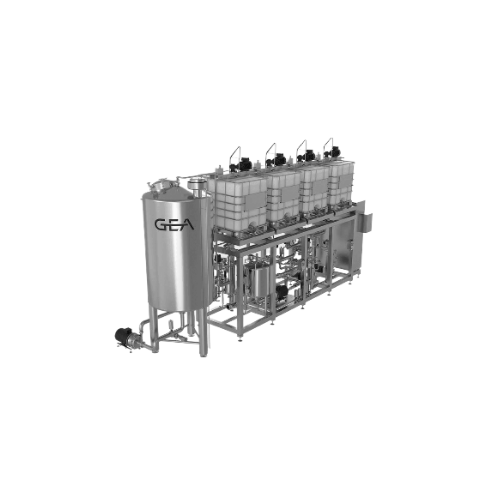

Pasteurizer for dairy concentrates

Ensure optimal flavor and texture in dairy products with precise pasteurization that pro...

Inline high shear mixing unit for low to medium viscosity products

Achieve precise emulsification and size-reduction wi...

Liquid confectionery metering system

Effortlessly integrate precision and flexibility in candy production by accurately met...

High-capacity filler and closer for pumpable products

Efficiently handle pumpable, flowable, and pasty products with this...

Lidding system for cups and trays

Enhance your packaging line with precise, space-saving lidding technology, ideal for seal...

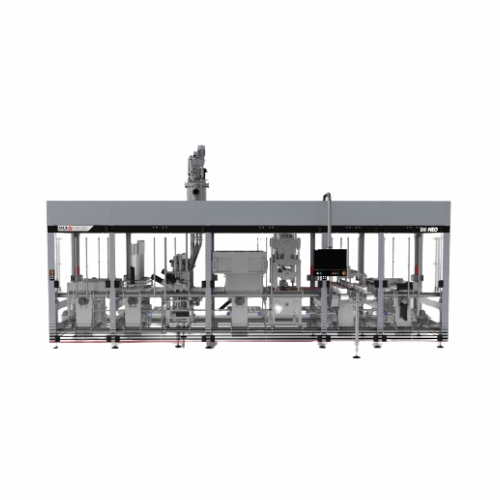

Top load and side load case packer with vision guided robotics

Optimize packing efficiency and flexibility with a versat...

Scraped surface sterilizer for high viscosity liquid products

Optimize your production of high viscosity liquids with a ...

Industrial homogenizer for food and beverage applications

For manufacturers seeking consistent quality, this homogenizer...

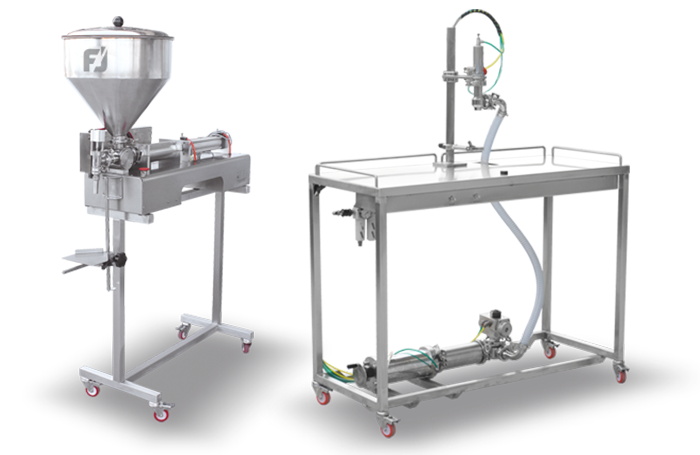

Depositing solutions for liquid and semi-liquid foods

Ensure consistent portioning and minimize waste with advanced depos...

Milk clarifier for dairy industry

Enhance your dairy production with efficient milk and whey clarification, ensuring produc...

Gasketed plate heat exchangers for hygienic applications

Ensure optimal hygiene and thermal efficiency in your processing...

Gasketed plate heat exchanger for hygienic applications

Achieve precise temperature control for sensitive products with a...

Sanitary static blender for food and beverage

Optimize your mixing process with low shear, energy-efficient blending desig...

Continuous in-line blender for dairy applications

Achieve precise and homogeneous blending of sensitive dairy mixtures di...

Industrial homogenizer for small and medium production

Enhance product stability and extend shelf life with our high-pres...

Ultraclean filling monoblocks for food industry

Enhance product safety and quality with monoblocks designed for ultraclean...

Horizontal stand-up pouching for beverages, dairy, and pet care

Optimize your liquid product packaging with rapid, high-...

Fully automatic filling lines for liquids

Achieve precise dosing and filling of liquids with minimal cycle times using com...

Emptying systems for high viscosity fluids and pastes

Efficiently empty high-viscosity fluids and pastes with precision, ...

Industrial depositor for automated recipe management

Effortlessly streamline your production with precise depositing cont...

Aseptic filler for various liquid and semi-liquid food products

For manufacturers focused on quality, this aseptic filli...

Aseptic filler for fruit juice and puree

Ensure optimal product safety and quality with this aseptic filler, designed to ha...

Aseptic filling solution for fruit juice and dairy products

Ensure product integrity and safety with this aseptic fillin...

Aseptic rotary cup filling and closing solution

Maximize your production capacity with this cutting-edge aseptic solution,...

Rotary cup filling and closing system

Maximize production efficiency with a system that offers precision filling and secure...

Forming, filling, and sealing system for liquid food products

Achieve precise portion control and versatile packaging wi...

Homogenizer for high-capacity food processing

Achieve superior emulsification and suspension handling with this high-press...

Fermentation tank for yogurt and fermented dairy products

Ensure perfect fermentation conditions for producing high-qual...

Dairy pasteurization system for milk, yoghurt, and cream

Ensure reliable dairy processing with an advanced pasteurization...

High shear mixer for dairy and beverage industry

Achieve consistent product quality with a high shear mixer, enabling seam...

Dairy pasteurizer

Ensure product safety and quality while reducing energy consumption and operational costs with this advance...

High-pressure homogenizer for dairy and beverage products

Achieve optimal product consistency and extend shelf life with...

Aseptic tank for intermediate storage

Ensure safe and sterile storage for liquid and slurry products, minimizing product lo...

Fermentation tank for dairy products

Achieve optimal fermentation conditions for high-quality yoghurt and fermented dairy p...

Dual-line filler for tetra top packages

Maximize your production flexibility with a high-speed, dual-line filling solution ...

Filling machine for tetra rex® gable top cartons

Maximize efficiency and food safety in high-speed liquid filling with pre...

Compact aseptic filling solution for versatile production

Maximize production line efficiency with a compact filling sys...

Versatile filling system for aseptic packaging

Achieve seamless integration in high-speed aseptic packaging with this flex...

Aseptic filling solution for liquid food packaging

Optimize liquid food production with advanced aseptic filling, ensurin...

Yogurt production line

Optimize your dairy production with a comprehensive solution that seamlessly transforms milk into a di...

Automated cup filling solutions for liquid and viscous products

Ensure precise and hygienic filling of dairy, baby food,...

High pressure homogenizer for dairy and pharmaceutical industries

When uniform texture and stable emulsions are critica...

Filler for yoghurt and white cheeses

For manufacturers seeking efficient, versatile filling for products like yoghurt and s...

High hygienic filler for chilled beverages

Enhance cold beverage production with a modular, hygienic filler offering chemi...

Yoghurt and dairy desserts filling solution

Maximize efficiency in filling and sealing multi-product dairy desserts and be...

High pressure plunger pump for continuous food processing

Achieve consistent texture and quality in spreads and sauces w...

Pilot plant homogeniser

From food to pharma, homogenization is an essential step in the production process that provides unif...

Pasteurization Machine for Milk

Manual processing of dairy products can cause inconsistent quality between batches due to po...

Semi-Automatic Volumetric Liquid Filling Machine

Filling containers manually with liquid and viscous products is the metho...

Batch cooker for fruit puree

The fruit pulp is used in many different bakery products, especially as a filling. Since fruit ...

Emulsifier and mixer for gelling agent

When making jams and marmalades, gelling agents, such as pectin, are used to thicken...

Concentrator for fruit puree preparation

Fruit puree is often an ingredient of various fruit-flavored yogurts, which someti...

Autoclave sterilizer for food cans and jars

An autoclave is a must-have machine for canned food production lines. It perfo...

Multifunction case packer for bottles and jars

New ways of packaging products are popping up all the time on the market. T...

Wrap-around case packer for cans or bottles

When it comes to beer packaging, most of the manufacturers use plain box carto...

Automatic filling and sealing machine for yogurt

One of the biggest challenges when filling yogurt in containers is that t...

Tunnel pasteurizer for beverage

In the beverage industry, beverages need to be pasteurized in order to destroy pathogens, an...

Flexible pasteurizer for packaged food

Autoclaves for sterilising and cooking food products are a mainstay of many producti...

Vacuum based homogenizer

When producing liquid and viscous products such as mayonnaise, sauces, dressings and ketchup it’s vi...

Economical Pouch Packaging Machine

The side gusset pouch is a popular packaging solution for medium formats, particularly f...

Modular HFFS Machine

A large range of sizes and types is available, with traditional horizontal form fill and seal machines b...

HFFS machine with servo-control system

Traditional HFFS machines use mechanical cams to drive the production path through t...

High-pressure homogenizer

When processes call for homogenized emulsions with extremely fine particle sizes the traditional t...

In-line laboratory dispersing machine

Innovators in a wide variety of industries need laboratory equipment on which process...