Nozzle separators for strained yoghurt production

Maximize yield and ensure consistency in your dairy production by integrating cutting-edge nozzle separator technology for precise texture setting and efficient whey separation.

Separates and Concentrates Dairy Products Efficiently

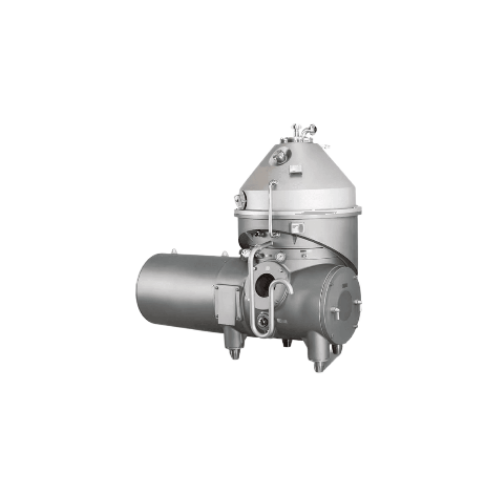

The Nozzle Separator KDB/KDE from GEA is an advanced centrifugal separator designed specifically for the dairy industry, excelling in separating and concentrating products like strained yoghurt, fresh cheese, and quark. Leveraging a high-speed rotating bowl, it utilizes centrifugal force to enhance product purity and consistency while minimizing losses. These separators support continuous operation and can adapt dynamically to different input feeds, ensuring a steady output flow with precise control over total solids content.

Ideal for applications such as Greek yoghurt and Icelandic skyr production, the machine improves yield and texture quality without the need for stabilizers. Its PLC-controlled automation integrates seamlessly into existing production lines, offering easy operation and real-time monitoring. The machine’s design supports cleaning-in-place (CIP), significantly reducing downtime for maintenance and ensuring hygiene standards are met.

Driven by a frequency-controlled 3-phase AC motor, the system is highly energy-efficient, reducing operational costs. Available in durable stainless steel, it guarantees long-term reliability in demanding environments. Its robust construction complies with global food safety standards, making it a reliable choice for dairy producers seeking sustainability and efficiency in their production processes. Furthermore, GEA offers customization and engineering support to tailor the equipment to specific production requirements.

Benefits

- Enhances product quality with consistent texture and solids content.

- Minimizes waste and increases yield through efficient separation.

- Reduces energy use with frequency-controlled motors.

- Integrates seamlessly into existing lines for streamlined operations.

- Maintains hygiene standards with CIP capabilities, minimizing downtime.

- Applications

- Strained yoghurt, Skyr, Fresh cheeses, Greek yoghurt, Labneh, Quark, Dairy products

- End products

- Greek style strained yoghurt, Dessert quark, High-protein strained yoghurt, Spreadable fresh cheese, Icelandic skyr, Flavored quark, Labneh cheese balls

- Steps before

- Milk Reception, Emulsification, Pasteurization, Homogenization, Culture Inoculation, Fermentation

- Steps after

- Concentration, Texture Adjustment, Direct Filling, Packing, Cooling

- Input ingredients

- quark, fresh cheese, labneh, skimmed milk yoghurt, Greek yoghurt, buttermilk, recombined milk, double cream fresh cheese from fat milk

- Output ingredients

- whey, strained yoghurt, fresh cheese, quark, labneh, Greek yoghurt, skyr, double cream fresh cheese

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Automation

- Fully automatic

- Centrifugal Force

- 10, 000 times gravity

- Continuous Operation

- Yes

- Cycle Time

- 16 hours minimum

- Motor Type

- Frequency-controlled 3-phase AC motor

- Product Loss

- Minimized

- Product Quality

- Repeatable

- Separation Efficiency

- High

- Solids Discharge

- Via nozzles

- Texture Control

- Precise

- Total Solids Percentage

- Adjustable

- Automation level

- Fully automatic

- Batch vs. continuous operation

- Continuous

- CIP/SIP

- Fully automatic cleaning-in-place (CIP)

- Energy efficiency

- High efficiency operation

- Air incorporation control

- Sterile air flow applied

- Changeover time

- Minimal due to automation

- Cleaning method

- CIP

- Machine footprint

- Compact design

- Feed method

- Closed system

- Discharge method

- Centripetal pump for whey, nozzle release for cheese

- Cooling system

- Ice water cooled parts

- Control panel type

- Frequency-controlled 3-phase AC motor

- Control panel type

- Frequency-controlled 3-phase AC motor

- Integration possibilities

- Easy integration into existing process line

- Automation level

- Fully automatic

- CIP capability

- Fully automatic cleaning-in-place (CIP)

- Cooling method

- Ice water cooling for smooth product discharge

- Product discharge

- Nozzles to solids catcher

- Operation control

- User-friendly interface

- Flexible production

- Options for precise setting of texture and solids

- Airflow control

- Sterile air flow to the hood space