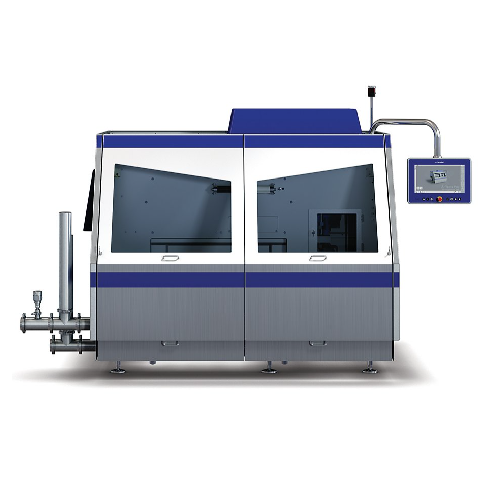

High-pressure homogenizer for dairy and beverage products

Achieve optimal product consistency and extend shelf life with efficient high-pressure homogenization, tailored for continuous processing of high-capacity liquid and slurry applications.

Homogenizes and Processes High-Pressure Emulsions and Suspensions

The Tetra Pak® Homogenizer 500 is engineered for high-volume food and beverage processing. It specializes in high-pressure homogenization of emulsions and suspensions, utilizing a robust multi-stage system for continuous operation. Ideal for products such as pasteurized milk, UHT milk, and plant-based beverages, it delivers flexible production from liquid to slurry. With a capacity of 63,600 liters per hour, it caters to large-scale operations while boasting significant energy efficiency due to HD EnergyIQ technology, resulting in reduced utility consumption and operational costs. Its advanced automation integrates seamlessly into existing lines, ensuring high uptime with low wear components designed for extended service intervals. Available in Outokumpu Circle Green® stainless steel, it offers exceptional durability and a reduced carbon footprint, meeting stringent sustainability goals. Enhanced for both aseptic and non-aseptic processing, it comes equipped with a CIP system for efficient cleaning and meets all industry-standard certifications, providing reliability and peace of mind for dairy producers, beverage manufacturers, and food processing companies.

Benefits

- Increases production efficiency with high capacity of 63,600 liters per hour.

- Reduces operational costs through optimized energy usage and lower utility consumption.

- Enhances product consistency with precise homogenization at variable pressures.

- Minimizes environmental impact by utilizing steel with up to 93% lower carbon footprint.

- Extends maintenance intervals, decreasing downtime and service costs.

- Applications

- Cream, Sauces, Rngs (rice, Grain or soy) beverages, Cheese, Tomato products, Dairy, Food, Ice cream, Liquid egg, Nut, Still drinks, Purées, Gravies, Plant-based products, Powder, Condensed milk, Concentrates, Juice, Nectar, Ketchups, Dressings, Mayonnaise

- End products

- Nut beverages, Sweetened condensed milk, Fruit purée, Protein powder, Tomato paste, Italian dressing, Liquid egg whites, Uht milk, Orange juice, Almond milk, Cream cheese, Beef gravy, Vanilla ice cream, Rice milk, Yogurt, Alfredo sauce, Soy milk, Vegan mayonnaise, Pasteurized milk, Apple concentrate, Tomato ketchup

- Steps before

- Heating, Emulsification, Mixing, Pasteurization

- Steps after

- Aseptic packaging, Cooling, Spray drying, Sterilization

- Input ingredients

- emulsions, suspensions, pasteurized milk, UHT milk, cream, yoghurt, condensed milk, ice cream mix, fruit juices, RNGS beverages, concentrates, purées, tomato products, dressings, ketchups, liquid egg, mayonnaise, sauces, gravies

- Output ingredients

- homogenized milk, homogenized dairy products, homogenized beverages, homogenized purées, homogenized tomato products, homogenized dressings, homogenized sauces and gravies

- Market info

- Tetra Pak is renowned for providing innovative packaging solutions, specializing in carton packaging for the food and beverage industry. It is esteemed for high-quality, sustainable, and efficient processing and packaging equipment on a global scale.

- Capacity

- 63, 600 litres/hour

- Homogenizing Efficiency

- Highest with HD EnergyIQ

- Utility Consumption

- Lowest in industry (water, steam, energy)

- Service Intervals

- Up to 40% longer on pistons, seals, and bearings

- Cooling Water Recirculation

- Up to 80% re-circulated

- Outlet Temperature of Condensate

- Minimum 110 °C

- Water and Steam Consumption

- Reduces by up to 70% steam and 80% water

- Energy Consumption

- Low electricity cost – 3 kWh per 1000 litres

- Emission Reduction

- Up to 93% lower CO₂

- Material

- Outokumpu Circle Green® stainless steel

- Modularity

- Variable pressure and capacity

- Aseptic Barrier

- High-temperature condensate

- High-pressure homogenization

- Yes

- Handling of emulsions and suspensions

- Yes

- Batch vs. continuous operation

- Continuous

- Variable pressure and capacity

- Yes

- Energy efficiency

- Low utility consumption

- High uptime design

- Yes

- Automation level

- Smart automation

- CIP/SIP capability

- CIP possible

- Water and steam usage

- Low, with serial cooling system

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Viscosity

- Low to High

- Aseptic processing compatibility

- Yes

- Foaming

- Controlled

- Material Option

- Outokumpu Circle Green® stainless steel

- Piston,Seals Service Life

- Up to 40% longer intervals