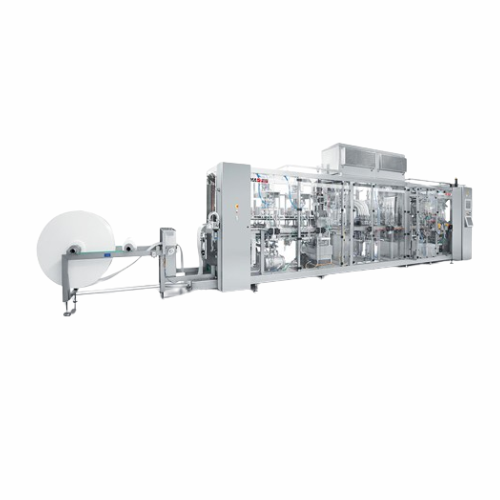

Form fill and seal solution for liquid and pasty products

Enhance your production efficiency with high-speed forming, filling, and sealing capabilities for liquid and pasty products, ensuring versatile cup design and labeling options while reducing packaging material costs.

Forms, Fills, and Seals Liquid and Pasty Products

The EF 400 from the IMA Group is a high-output Form, Fill, and Seal machine designed to optimize packaging for a range of liquid to pasty products, particularly in the food and dairy sectors. It stands out with its ability to process multi-layer materials such as PS, PET, and PP, providing versatility in cup design and labeling options. The EF 400 achieves impressive throughput, handling up to 46,000 yogurt cups per hour with precision thanks to its accurate dosing technology, minimizing product loss. Its operations can be tailored to clean, ultra-clean, or aseptic standards, making it suitable for sensitive product packaging. The machine is PLC-controlled, integrating smoothly into high-speed lines, and can be equipped with multiple fillers to meet various product specifications. Additionally, it meets FDA, 3A, and EHEDG compliance requirements, ensuring it adheres to stringent hygiene and safety standards. The EF 400 also features quick changeovers and easy maintenance, with optional CIP systems for efficient cleaning. Customization options include various labelling techniques and filler configurations to address specific production needs.

Benefits

- Increases production efficiency by processing up to 46,000 cups per hour.

- Reduces material costs through innovative cup design and labelling flexibility.

- Ensures high hygiene standards with clean, ultra-clean, and aseptic configurations.

- Enhances product stability and package strength with versatile labelling options.

- Minimizes product waste with precise and accurate filling technology.

- Applications

- Fresh cheese, Desserts, Yogurt, Purees, White cheese, Fruit juice

- End products

- Orange juice containers, Greek yogurt cups, Ricotta cheese tubs, Apple puree pouches, Cottage cheese pots, Chocolate mousse desserts

- Steps before

- Ingredient preparation, Mixing, Pre-heating, Emulsification

- Steps after

- Sealing, Labelling, Packaging, Palletizing

- Input ingredients

- pasty products, liquid products, multi-layer materials, PS, PP, PET, PS/PE, PS/PETG, PS/EVOH/PE, PP/EVOH/PP

- Output ingredients

- cups, yoghurt pots, fresh cheese cups, desserts, fruit juice, purees, yogurt, white cheese

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Cup material width

- 410 mm

- Draw off length

- 300 mm

- Usable width

- 390 mm

- Forming depth

- 100 mm

- Output (with label)

- 2 rows of 6 cups of fresh cheese up to 23, 000 cups/h

- Output (yoghurt pots)

- 4 rows of 6 cups up to 46, 000 cups/h

- Hygiene class

- Clean, Ultra-Clean, Aseptic

- Standard Equipment Controller and Servomotors

- ELAU

- Standard Equipment Pneumatics

- FESTO

- HMI

- 15’’

- Bottom web reel

- Ø 1200 mm

- Lid reel

- Ø 400 mm

- Label reel

- Ø 600 mm

- Standard Equipment Chains

- ERCA chains with grippers and magnetic drive

- Materials

- PS, PET, PP and multilayers

- FDA,3A and EHEDG-compliant

- On demand

- Filling accuracy

- Outstanding filling accuracy

- Customization

- Countless customized and tailor-made design possibilities

- Working Mechanism

- Form Fill Seal (FFS)

- Integrated Steps

- Forming, Filling, Sealing

- Batch vs. Inline Flow

- Inline Continuous

- Automation Level

- PLC-controlled

- Changeover Time

- Quick and Easy

- CIP/SIP

- Depending on customer specification

- Cleaning Method

- Clean, Ultra-Clean, Aseptic

- Cup Design Versatility

- Cost-effective with customized options

- Material Handling

- Handles PS, PET, PP, multilayers

- Labeling Techniques

- Straight, Conical IML, In-mould Sticker

- Output Capacity

- 23, 000–46, 000 cups/h, depending on product type

- Multilayer materials

- PS/PE, PS/PETG, PS/EVOH/PE, PP/EVOH/PP

- Forming depth

- 100 mm

- Usable width

- 390 mm

- Bottom web reel diameter

- Ø 1200 mm

- Lid reel diameter

- Ø 400 mm

- Label reel diameter

- Ø 600 mm

- Control panel type

- HMI 15’’

- Material Compatibility

- PS, PET, PP and multilayers such as PS/PE, PS/PETG, PS/EVOH/PE, PP/EVOH/PP

- Labelling Options

- Straight or conical IML, in-mould sticker labels, labelling with vacuum, automatic splicing

- Hygiene class

- Clean, Ultra-Clean, Aseptic

- Chains

- ERCA spiked chains, standard spiked chains, TSUBAKI chains

- Fillers

- Up to 3 fillers