Cup filling and sealing system for dairy products

Optimize your production line with versatile cup filling and sealing capabilities, perfect for accommodating diverse product types and maximizing throughput efficiency.

Fills, Seals, and Overcaps Diverse Product Ranges

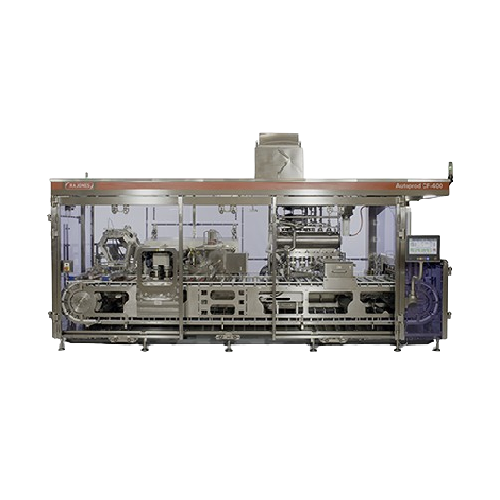

The Autoprod CF-400 from R.A Jones is a versatile cup filling and sealing machine specifically engineered for the food, dairy, and pet care industries. It efficiently handles liquid and solid products, utilizing an inline indexing system for precise filler, sealer, and overcapper applications. Capable of operating up to 400 cups per minute, it is ideal for products ranging from Greek yogurt and cheddar cheese slices to canned dog food and olive oil bottles. This 3-A certified equipment offers swift changeovers—10 minutes for product and 20 minutes for size—minimizing downtime and maximizing productivity. Integration into existing production lines is seamless, with intermittent and high-speed operational modes to meet varying demands. Comprised of durable materials suitable for food-grade applications, the Autoprod CF-400 supports both plastic and paperboard packaging, ensuring compliance with industry standards for safety and efficiency.

Benefits

- Enhances production efficiency with rapid product and size changeovers.

- Supports diverse product types, increasing flexibility across multiple industries.

- Minimizes operational costs with reliable high-speed performance.

- Ensures product integrity with precise filling and sealing mechanisms.

- Complies with industry standards, providing assurance of safety and quality.

- Applications

- Food, Pasta, Pet food, Fats, Noodles, Oils, Stock cubes, Cheese, Yoghurt, Soup, Rice, Dairy

- End products

- Fruit yogurt cups, Cheddar cheese slices, Shredded mozzarella, Olive oil bottles, Greek yoghurt, Butter tubs, Basmati rice packs, Chicken stock cubes, Instant noodle cups, Canned dog food

- Steps before

- Mixing, Blending, Ingredient Preparation

- Steps after

- Sealing, Overcapping, Labeling, Packaging, Inspection

- Input ingredients

- raw food ingredients, dairy products, pet food ingredients, oils, fats, pasta, noodles, rice, soup ingredients, stock cubes, cheese, yoghurt

- Output ingredients

- filled cups, sealed containers, overcapped packages, packaged yogurt, packaged cheese, packaged pet food, packaged oils, fats, packaged pasta, packaged soup, packaged dairy products

- Market info

- R.A Jones (Coesia Group) is known for its expertise in designing and manufacturing packaging equipment and automation solutions, specializing in cartoning, pouching, and high-speed filling, with a strong reputation for innovation and reliability in the industry.

- Automation

- Inline indexing

- Max Filling Speed

- 400 cpm

- Compliance,Certifications

- 3-A certified

- Filling volume

- 20 ml – 1650 ml

- Footprint

- Depth

- Machine Weight

- 12247 kg

- Operating mode

- Intermittent

- Product changeover time

- 10 minutes, 1 person

- Size changeover time

- 20 minutes, 2 people

- Max Pack Height

- 152 mm

- Min Pack Height

- 38 mm

- Max Pack Length

- 133 mm

- Min Pack Length

- 76 mm

- Max Pack Width

- 140 mm

- Min Pack Width

- 50 mm

- Packaging Material

- Plastic, Paperboard

- Packaging Shape

- Round, Square, Oval, Rectangle, Special

- Packaging Type

- Cup, Tray, Tubs, Pails

- Working mechanism

- Inline indexing, filler, sealer and/or overcapper

- Operating speed

- Up to 400 cpm

- Automation level

- Intermittent mode

- Changeover time

- Product changeover

- Size changeover

- 20 minutes, 2 people

- Packaging versatility

- Round, square, oval, rectangle, special

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product type compatibility

- Food, Dairy, Pet Food

- Machine depth

- 2097 mm

- Machine height

- 2705 mm

- Machine length

- 7450 mm

- Machine weight

- 12247 kg

- Intermittent Operation

- Yes

- Control Panel Type

- Touchscreen