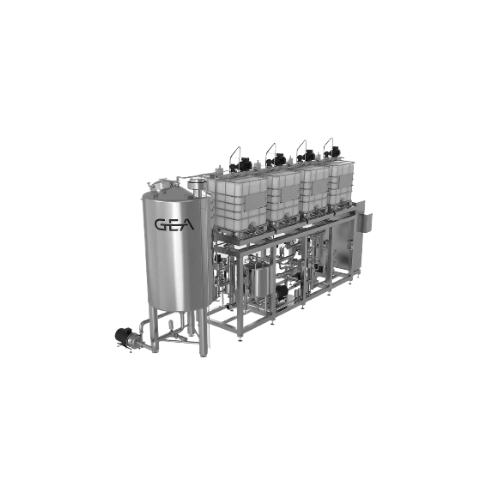

Continuous in-line blender for dairy applications

Achieve precise and homogeneous blending of sensitive dairy mixtures directly in your production line, minimizing equipment and maximizing efficiency without the need for additional mixing tanks.

Blends and Standardizes Dairy Products In-Line

The GEA DICON® Continuous In-line Blender is a sophisticated solution for dairy processing, specifically designed to streamline the blending and standardization process directly in the production line. This system excels in applications such as yogurt and fruit mixtures, milkshake bases, and flavored milk production. Utilizing a dynamic mixer and precise metering devices, it ensures homogeneous blending without the need for additional mixing tanks, promoting product consistency.

Capable of handling sensitive ingredients with a gentle touch, the rotary piston pumps work at low flow rates to prevent crushing. These frequency-controlled pumps eliminate the need for modulating valves, reducing maintenance concerns and enhancing operational efficiency. The system is compact, workshop-tested, and features digital controllers that maintain accurate ingredient ratios, even when throughput varies.

Designed with versatility in mind, the GEA DICON®-Y model processes up to 1.000.000 CP and supports fast product availability due to minimal system inclusion. It offers seamless integration into automated production lines, contributing to energy efficiency by optimizing motor usage. Ideal for dairy producers and yogurt manufacturers, this in-line solution meets industry standards and accommodates customization to match specific production needs.

Benefits

- Enhances product consistency by ensuring precise, homogeneous blending directly in-line.

- Minimizes operational costs by eliminating the need for additional mixing tanks.

- Reduces energy usage with frequency-controlled pumps, eliminating modulating valves.

- Streamlines production with quick product availability and minimal system cleaning.

- Supports high-capacity processing, handling up to 1.000.000 CP efficiently.

- Applications

- Yogurt, Fruit mixtures, Milk-based products, Dairy

- End products

- Probiotic dairy drink, Fruit-infused yogurt, Fruit yogurt, Milkshake base, Yogurt drink, Low-fat dairy drink, Strawberry yogurt, Chocolate milk, Greek yogurt, Flavored milk

- Steps before

- Milk Standardization, Ingredient Preparation

- Steps after

- Packaging, Quality Assurance, Cooling

- Input ingredients

- yogurt, fruit, liquid media, milk-based products, sensitive ingredients, coarse particles

- Output ingredients

- blended yogurt and fruit, standardized milk-based products, homogeneously mixed products

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Blending System

- Continuous In-line

- Accuracy

- Precise metering devices

- Capacity

- Up to 1, 000, 000 CP

- Automation

- Digital controller

- Mixing Technology

- Dynamic Mixer

- Pump Type

- Rotary piston pumps

- Pump Control

- Frequency controlled

- Blending Process

- Continuous In-line

- Automation Level

- Digital Controller

- Product Mixing

- In-pipeline, no mixing tanks

- Gentle Product Processing

- Low flow rate rotary piston pumps

- Versatility

- Up to 1, 000, 000 CP

- Dynamic Mixer Features

- Prevents system blockage

- Batch vs. Continuous Operation

- Inline Continuous

- Compact Design

- Workshop-tested system

- Precise Metering Devices

- Ensures accurate blending

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Heat sensitivity

- Sensitive

- Ingredient Compatibility

- Dairy and fruit

- Discharge method

- In-line, in the pipe

- Control panel type

- Digital controller

- Integration possibilities

- In-line blending

- Compact footprint

- Yes