Pipeline inspection for liquid and paste-like products

Ensure your liquid and paste-like products are free from foreign objects with advanced X-ray inspection technology, providing precise detection before packaging to prevent costly recalls and waste.

Detects and Rejects Foreign Objects in Pipelines

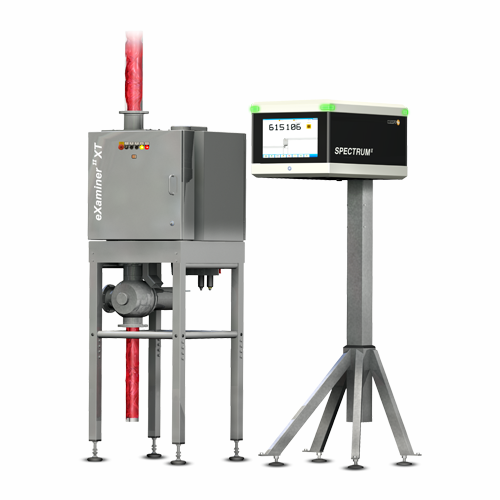

The HEUFT eXaminer II XT, developed by HEUFT SYSTEMTECHNIK, is a cutting-edge pipeline X-ray inspector that enhances product safety for beverage, food, and pharmaceutical manufacturers. Utilizing advanced pulsed X-ray technology, it efficiently detects high-density foreign objects in liquid and slurry products before they reach packaging, minimizing food and packaging waste. With real-time image processing and the HEUFTreflexxA.I. system, it provides unmatched detection reliability and differentiation between genuine and false threats. Engineered for continuous high-speed operations, it integrates seamlessly into existing production lines with comprehensive automation supported by the powerful HEUFT SPECTRUM II platform. The equipment’s hygienically optimized HEUFTCleanDesign ensures easy cleaning, while robust components promise reduced total cost of ownership and enhanced operational longevity.

Benefits

- Ensures product safety by detecting and rejecting contaminants before packaging.

- Reduces operational costs with minimal food and packaging waste.

- Maintains high production speeds with reliable detection even during fluctuations.

- Simple maintenance and long lifespan lead to lower total cost of ownership.

- Improves line efficiency with seamless integration and real-time monitoring capabilities.

- Applications

- Food, Beverages, Sauces, Vegetable preparations, Jams, Yoghurt, Fruit preparations, Sausage meat, Tomato paste, Syrups, Pharmaceuticals

- End products

- Ketchup, Medicinal syrups, Strawberry jam, Fruit compote, Fruit yogurt, Pickle relish, Cough syrup, Pasta sauce, Honey, Greek yogurt, Luncheon meat, Sausage links, Juice, Soft drinks, Beer, Tomato ketchup

- Steps before

- Mixing, Blending, Homogenization

- Steps after

- Packaging, Quality Check, Distribution

- Input ingredients

- liquid product mass, paste-like product mass, sauce, jam, syrup, fruit preparations, vegetable preparations, yoghurt, tomato paste, sausage meat

- Output ingredients

- pre-inspected goods free of foreign objects

- Market info

- HEUFT is known for its expertise in inline quality inspection systems and automation solutions for the food, beverage, and pharmaceutical industries, with a reputation for innovation and reliability in ensuring product safety and integrity.

- Detection type

- Pulsed X-ray

- Exposure time

- Millisecond

- Automation

- HEUFTSPECTRUMII platform

- Image processing

- HEUFTreflexxA.I.

- Operational reliability

- Self-diagnosis

- Radiation level

- Low

- Inspection speed

- High / Fluctuating transport speeds

- X-ray beam type

- Single beam

- Detection Method

- Pulsed X-ray

- Product Flow

- Inline Continuous

- Inspection Speed

- High / Fluctuating

- Automation Level

- Highly Automated

- Fault Rejection

- Precision Rejection Valve

- Cleaning Method

- HEUFTCleanDesign

- Performance Validation

- Self-diagnosis Test Program

- Human-Machine Interface

- HEUFTNaVi

- Networking Capability

- Online Connection via Gigabit Ethernet and TCP/IP

- Image Processing

- Real-time with AI (HEUFTreflexxA.I.)

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Inspection purpose

- Foreign object identification

- Compact footprint

- Yes

- Hermetically sealed pipeline

- Yes

- Control panel type

- Touchscreen User Interface

- Discharge method

- Rejection Valve

- Control panel type

- Audiovisual user interface

- Integration possibilities

- HEUFT SPECTRUM II platform

- Discharge method

- Automatic rejection valve

- Compact footprint

- Optimized for space efficiency

- Networking capabilities

- Gigabit Ethernet, TCP/IP, SQL/DDE

- Machine learning integration

- HEUFT reflexx A.I.

- Automated adjustments

- Brand and format changes without manual intervention