Aseptic filler for various liquid and semi-liquid food products

For manufacturers focused on quality, this aseptic filling machine ensures that liquid and semi-liquid food products are safely packaged, maintaining product integrity through precise sterilization and filling processes.

Fills and Sterilizes Liquid and Slurry Products

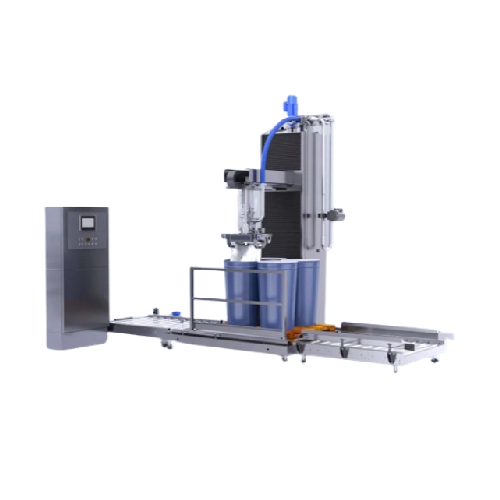

The Aseptic Filler TETI/1 MOD.EA-1C-BD from Tropical Food Machinery is engineered to enhance the efficiency of liquid and slurry product packaging. This equipment features a single aseptic filling head with steam sterilization, ideally suited for filling fruit juices, purees, creams, sauces, and dairy products while maintaining sterility. The EA-1C-BD operates at up to 7,000 liters per hour, capable of filling pre-sterilized bags into 220-liter drums or 1000-liter bins and goodpacks, with precision in product dosage ensured by integrated flow meters and PLC control. It accepts both common nozzle sizes, adapting between 1” for liquids and 2” for chunkier products. The system is FDA compliant and automates key operations from sterilization to cleaning, bolstered by an HMI touch-screen interface for monitoring and error management. Compact yet robust, with dimensions of 5700 x 3200 x 4000 mm, it integrates seamlessly into existing production lines, driving productivity in the food and beverage, dairy, and fruit processing industries.

Benefits

- Ensures product sterility, reducing contamination risks during filling and packaging processes.

- Increases production efficiency with automated operations, minimizing manual intervention and labor costs.

- Adapts to varying product viscosities, accommodating a wide range of liquid and slurry products.

- Enhances operational reliability with FDA-compliant safety standards and PLC-driven error management.

- Streamlines integration into existing systems, optimizing filling processes without extensive setup time.

- Applications

- Jellies, Sauces, Milk products, Fruit purees, Ice cream bases, Fruit juices, Tomato products, Yogurts, Creams

- End products

- Strawberry jam, Orange juice, Almond milk, Vanilla ice cream mix, Mango pulp, Tomato paste, Apricot yogurt

- Steps before

- Extraction, Pasteurization, Blending

- Steps after

- Packing, C.I.P. Washing, Sterilization

- Input ingredients

- fruit juice, juice with pieces of fruit, puree, fruit-based liquid, cream, sauce, jelly, yogurt, milk, base for ice cream, chopped tomato in sauce

- Output ingredients

- filled pre-sterilized bags, filled drums, filled bins, filled goodpacks

- Market info

- Tropical Food Machinery is known for manufacturing engineered-to-order (ETO) industrial equipment, specializing in fruit and vegetable processing machinery. They are reputed for innovation, quality, and global service in the food processing industry.

- Aseptic filling head

- Steam sterilization

- Capacity

- Up to 7, 000 l/h

- Filling formats

- 220 l drums / 1000 l bins

- Max. capacity with NFC juice

- 27 bags/h (220 l)

- Max. capacity with concentrated product

- 4500 l/h

- Max. capacity with shredded product

- 4500 l/h

- Dimensions (L x W x H)

- 5700 x 3200 x 4000 mm

- Electric power installed

- 4 kW

- Steam Consumption

- 50 Kg/h

- Compressed Air Consumption

- 600 nl/h

- Automation

- PLC-controlled

- Working mechanism

- Aseptic filling with steam sterilization

- Integrated steps

- Sterilization, filling, C.I.P. washing

- Automation level

- PLC-controlled

- CIP/SIP

- CIP integrated

- Batch vs. continuous operation

- Batch

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- 5700 x 3200 x 4000 mm

- Filling head type

- Aseptic, single head

- Control panel type

- HMI touch-screen interface

- Discharge method

- Pre-sterilized bags into 220 L drums or 1000 L bins

- Control panel type

- HMI touch-screen