Creams

Find innovative production technology for making creams and connect directly with world-leading specialists

Let's navigate the complex world of engineered-to-order production technology together. Whether you're building a new process or optimizing an existing line, our platform connects you directly to the experts who can help. Use our curated catalogue to dive straight into the technologies that match your production goals. We continuously map out how production technology from suppliers around the world can help solve real production challenges. If you find something interesting, we introduce you directly to the specialists who know how to implement it. With more than 600 trusted machine manufacturers and over 20.000 technical experts in our network, you’re never far from the answers you need.

Tell us about your production challenge

Processing steps involved in creams making

Which creams technology do you need?

Blending and mixing unit for dairy and beverages

Achieve precise recipe control and high-quality results by seamlessly int...

High shear emulsifier for mayonnaise production

Streamline your production of high-quality emulsions with this high-capaci...

High shear emulsifier for food and pharmaceutical products

Optimize your production line with precise emulsification, ho...

Heat exchangers for efficient heat transfer in industry

Achieve precise temperature control across diverse viscosities wi...

Precise liquid cooling solution for food processing

Ensure high-quality preservation of flavors and textures in liquid fo...

Continuous nut paste production line

Elevate your production efficiency with a versatile preparation line designed to seaml...

Continuous mustard production line

Optimize your condiment production with precision-engineered systems capable of transfor...

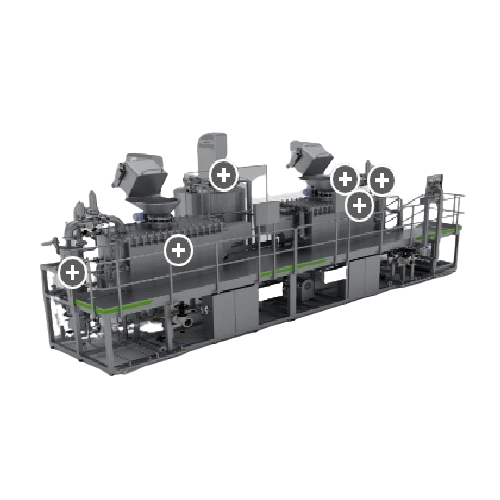

Cheese blending and heating line for processed cheese

Optimize your processed cheese production with a solution that seam...

Continuous caramel production line

Optimize your caramel production with seamless integration, achieving precise fat meltin...

Industrial cooker for sauces and stews

When producing diverse culinary delights such as sauces and stews, achieving even he...

Continuous heat exchanger for soups and sauces

Optimize your soup and sauce production with a continuous heat exchanger th...

Efficient cooling and cooking systems for food processing

Streamline your production with integrated cooling and cooking...

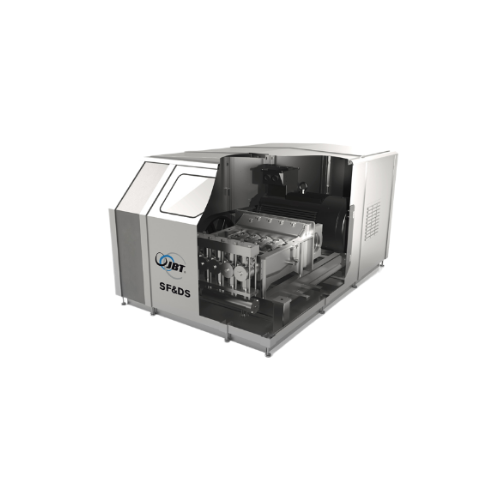

Industrial cutting system for fine emulsions

Optimize your production line with precision cutting and emulsifying, ensurin...

Vacuum deaeration system for mustard and liquid detergents

Ensure optimal product quality by effectively removing air fr...

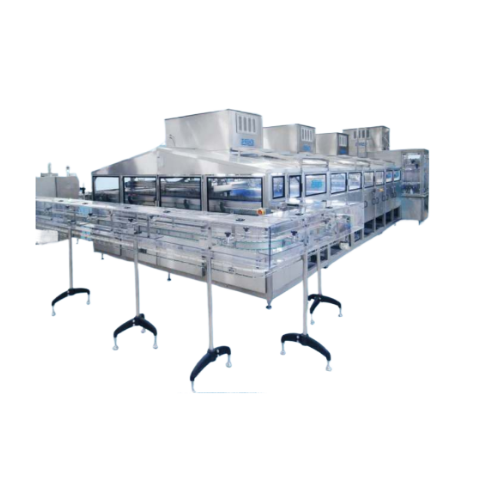

Cleaning systems for food, pharmaceuticals, and cosmetics

Ensure optimal hygiene and safety with advanced cleaning syste...

Continuous caramel process line

Optimize your continuous food processing with an engineered-to-order line tailored for preci...

Continuous cheese line

Achieve precise temperature control and seamless product transitions with this equipment, ideal for en...

Continuous mustard line

Streamline mustard production with high-capacity continuous processing that reduces air pockets and e...

Continuous tahina production line

Streamline your tahina production with precise grinding and controlled cooling, ensuring ...

Industrial yogurt production line

Streamline your yogurt production with precise process control to ensure consistent quali...

Stainless steel process vessels for biopharmaceutical applications

Ensure seamless mixing and sterilization with engine...

Inline processing system for food and beverage production

Optimize your production line with a versatile inline processi...

Automatic filtration system for beverage industry

Enhance your beverage production with a multi-stage filtration system t...

Industrial cooling vessel for ready meal components

Enhance your production with precise cooling and gentle handling of t...

Compact production unit for liquid food products with varied viscosities

Streamline your batch production with this ver...

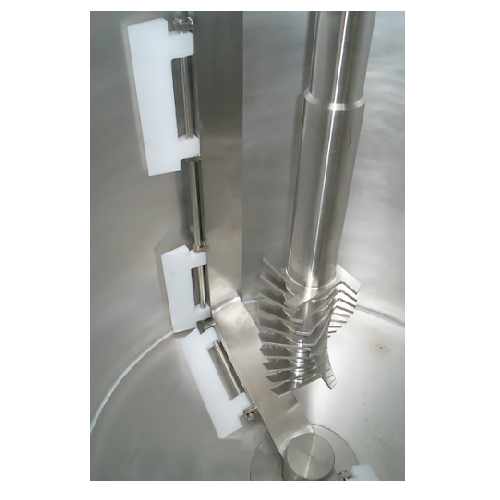

Scraped surface heat exchanger for food processing

Efficiently handle temperature-sensitive food products with a compact ...

Aseptic thermal processor for high viscosity products

Optimize your processing of high viscosity products with precise te...

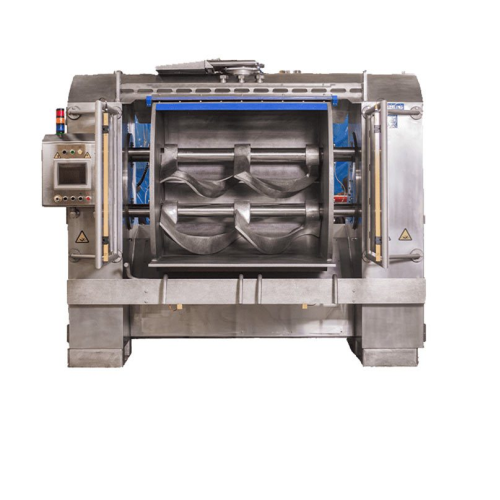

Open frame mixer for bread and pastry dough

Enhance your dough consistency and reduce production downtime with a robust, h...

Open frame mixer for bread and dough applications

Enhance baking productivity with a versatile mixer designed for efficie...

Medium duty mixer for dough preparation

Achieve perfect dough consistency across various products with a versatile medium d...

Traditional enclosed frame mixer for dough and batter preparation

Optimize your production with high-capacity mixing, e...

Industrial enclosed frame mixer for high-capacity dough mixing

Optimize your bakery’s output with a mixer designed...

Co-extruder for filled sweet and savoury products

Effortlessly create a variety of filled sweet and savoury products, fro...

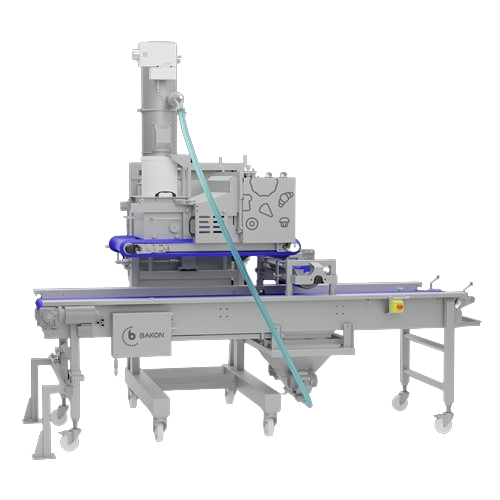

Industrial cream doser for pastry applications

Efficiently dose and fill a variety of bakery and confectionery mixtures wi...

Professional dosing system for creams and sauces

Streamline your production with precise dosing of creams and sauces, tail...

Lab-scale liquid and cream filling system

Streamline your lab production with precise filling of liquids, creams, and past...

Laboratory filling system for liquid and creamy products

Optimize your laboratory processes by precisely handling liquid,...

Versatile industrial melter for raw ingredients

Enhance your formulation capabilities with a flexible melter designed for ...

Industrial melter for cosmetic product processing

Streamline your production with this versatile melter, designed to effi...

Vacuum turboemulsifier for liquid and creamy products

Achieve precise emulsification and mixing of liquid and creamy form...

Vacuum turboemulsifiers for liquid and creamy products

Simplify your production workflow with high-capacity vacuum turboe...

Vacuum turboemulsifier for medium-scale production

Achieve precise emulsification and consistent quality in liquid and cr...

Vacuum turboemulsifier for small-scale production

Optimize your product development with versatile vacuum turboemulsifier...

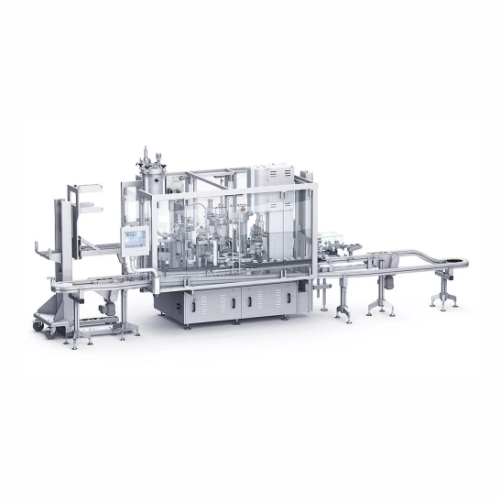

Automatic rotary jar filling and capping system

Optimize your personal care product line by efficiently filling and cappin...

Stickpack filling and closing system

Optimize your stickpack production with precise dosing, uniform sealing, and seamless ...

Sachet filling and closing system

Optimize your production line with a versatile solution designed to fill, seal, and count...

Automatic sachet filling and sealing system for liquids and creams

Optimize your cosmetic and personal care production ...

Heating and cooling system for food and dairy products

Achieve precise temperature control and efficient processing with ...

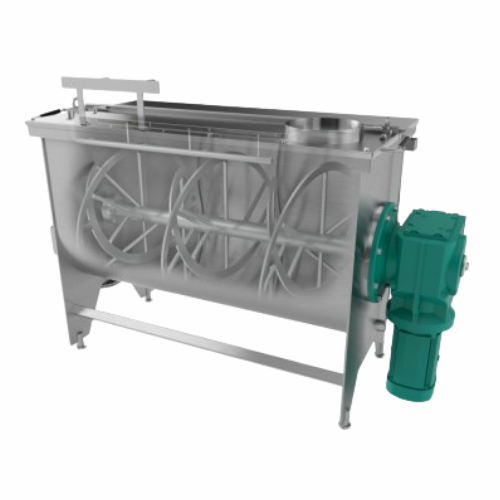

Industrial powder blender

Optimize your production with precise dry blending, ensuring efficient mixing processes and seamle...

High-shear inline mixer for lump-free products

Achieve consistent texture and prevent clumping in liquid and powder blends...

Stand dispersing unit for pilot plant applications

Achieve precise particle size reduction and efficient mixing with this...

Hygienic pipeline product recovery system

Efficiently recover valuable residuals from pipelines while streamlining your cl...

Sanitary pigging system for viscous food products

Efficiently recover high-value viscous products like chocolates and cre...

Double cone blender for homogeneous solid-solid mixtures

Need uniform blending for complex solid mixtures with diverse de...

Counter-rotating blender for cosmetic and pharmaceutical mixing

Achieve precise mixing and homogenizing of complex formu...

Hydrocolloid powder dispersion unit

Achieve seamless dispersion of hydrocolloid powders in liquids, eliminating common issu...

Portable agitator for high-speed mixing

Enhance your liquid formulation processes with an efficient solution for rapid mixi...

In-line high shear mixing solution

Achieve precise emulsification and particle size reduction with high shear capabilities,...

High shear vertical mixer for dispersion and emulsification

Achieve seamless emulsification and homogenization in divers...

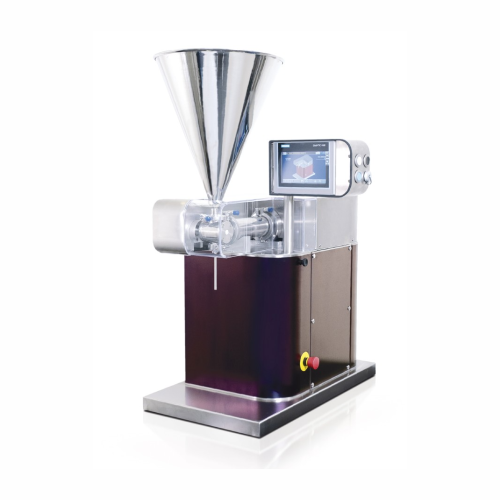

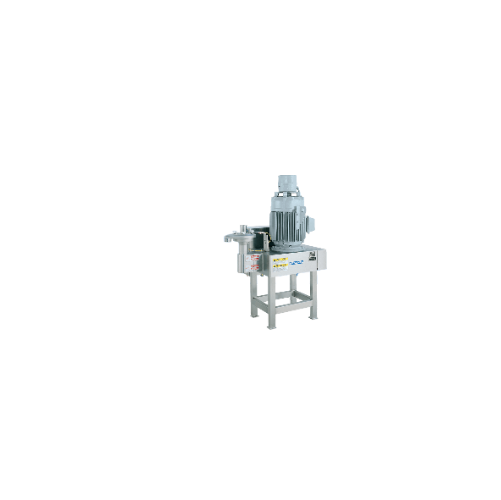

Cone mill for particle size reduction in pharmaceuticals

Achieve precise particle size control with this cone mill, desig...

Rotary filling and sealing for liquid to pasty products

Boost production efficiency with a flexible rotary solution that ...

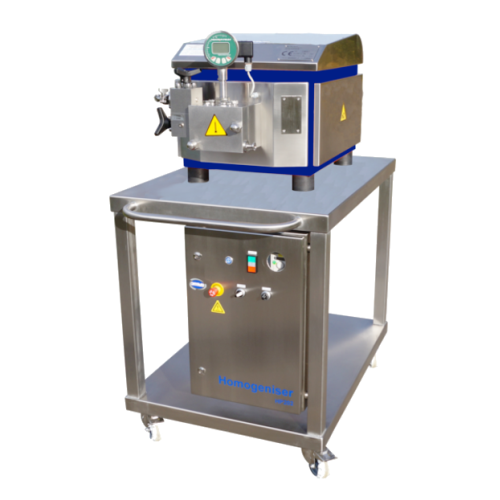

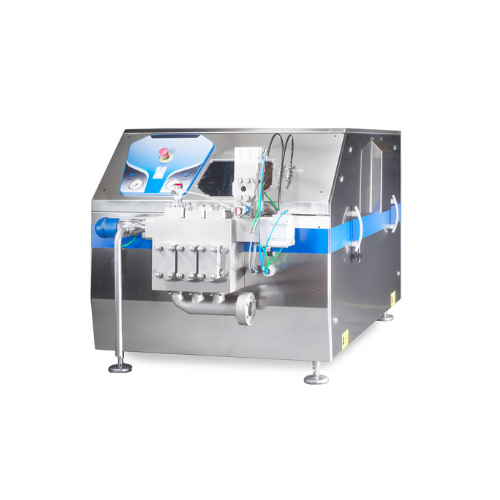

High-pressure homogenizers for liquid products

Achieve consistent emulsions and stable dispersions with high-pressure homo...

Homogenizer for high-pressure homogenization

Optimize your production with high-pressure homogenization, essential for ach...

Dual shaft mixer for high viscosity products

Achieve uniform dispersions in high-viscosity processes with a dual-shaft mix...

Triple shaft mixer for high viscosity products

Achieve uniform mixing and dispersion for high-viscosity materials with tri...

High-performance cartoning system for pharmaceutical products

Optimize your packaging line with a flexible cartoning sol...

High-precision depositing system for fluid and viscous fillings

Achieve precise and efficient dosing for diverse food pr...

Filling and sealing system for creams and lotions

Achieve precise, high-speed filling and secure sealing of cosmetic cont...

Ribbon blender for homogeneous blending of solids

Achieve perfectly consistent blends with a ribbon blender that ensures ...

Scraped surface heat exchanger for high viscous products

Efficiently handle the cooling and heating of high viscous produ...

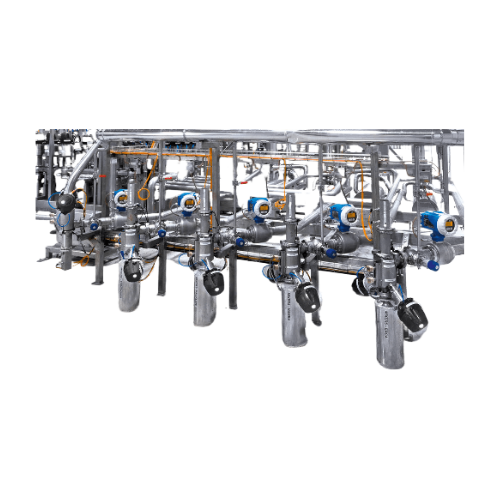

Stainless steel skids for food process integration

Optimize your production process with compact stainless steel skids th...

Stainless steel buffer tanks for food, pharma, and cosmetics

Ideal for maintaining process fluidity, these stainless ste...

Stainless steel agitators for pharmaceutical and food applications

Optimize your production line with tailored agitator...

Stainless steel chocolate tank for storage and processing

Efficiently control temperature and consistency for chocolate ...

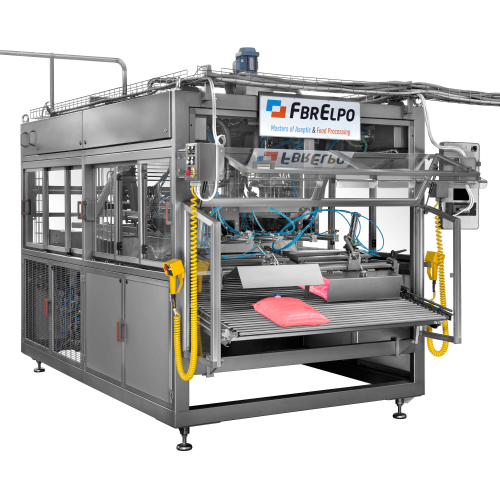

Aseptic filler for bag in box packaging

Optimize your bag-in-box packaging process with high-speed aseptic filling, ensurin...

Planetary mixer for industrial pastry production

Achieve precise dough consistency and enhance baked goods quality with th...

Planetary mixer with double tool for pastry dough

Optimize your pastry production with precise mixing capabilities that e...

Planetary stirrer for creams and ointments mixing

Achieve homogeneous mixing of creams, ointments, and pastes efficiently...

Precision ointment filling and dosing system

Achieve precise filling of liquid formulations with a versatile system capabl...

Vacuum processing units for lab scale applications

Optimize the development and scaling of cosmetic and pharmaceutical pr...

Vacuum processing units for high-viscosity products

For manufacturers seeking to streamline production of high-viscosity ...

Inline system for personal care product production

Optimize your personal care production with precise mixing, heating, a...

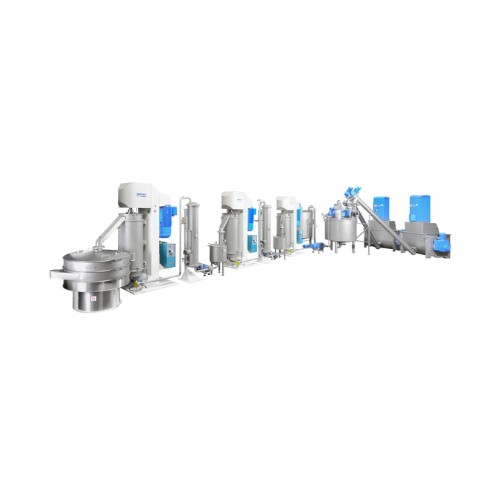

Pharmaceutical granulation line

Streamline your production with an integrated system that combines mixing, granulation, and ...

Planetary stirrer for creamy and foamy masses

Achieve consistent texture and optimal air incorporation in your products wi...

Interchangeable tool stainless steel kneader

Streamline your batch processing with this flexible mixing technology that of...

Fully automatic chocolate processing line

Accelerate your chocolate and confectionery production with this high-speed syst...

Chocolate processing production line

Efficiently streamline your chocolate and compound production with a fully automatic s...

Linear intermittent motion filling system for high-density liquids

Ensure precise dosing of high-density liquids like c...

Horizontal evaporation bowl for fruit jams and purees

Optimize thermal exchange and preserve product integrity during jam...

Evaporator for juices and purees

Efficiently concentrate liquid products like apple juice, tomato puree, and chocolate sauce...

Evaporators for fruit and vegetable juices and purees

Optimize your juice and puree production with advanced evaporators ...

Frozen product cleaning and sizing system

Achieve precise cleaning and sizing of frozen goods effortlessly, enhancing prod...

Vacuum degasser for juices and purees

Enhance the quality of your liquid products with efficient degassing and flavor recov...

Pressure equipment directive (ped) compliant tanks

Achieve precise pressure regulation and safety with tanks designed to ...

Vibrating tables for dewatering and sizing

Optimize your processing line with versatile vibrating tables designed to effic...

Shelling mill for Iqf and frozen fruit lumps

Effortlessly process frozen fruit and vegetable conglomerations into shelled ...

Turbo extractor for puree and concentrate production

Enhance your puree and concentrate production with a turbo extractor...

Chestnut puree production plant

Optimize your chestnut product line with a versatile production plant capable of transformin...

Systems for transporting cocoa powders and ingredients

Efficiently transport and dose your cocoa powders and semiliquid i...

Lumps melting system for chocolate and cocoa mass

Efficiently transform solid butter, grease, and chocolate into uniform ...

Storage tank for oils and greases

Efficiently store and preserve various liquid products with integrated heating, cooling, ...

Storage tank for dairy products and juices

Designed for optimal preservation and hygiene, these storage tanks prevent sedi...

High-pressure reactor for cosmetic and pharmaceutical production

Ensure precise formulation and enhanced product stabili...

Drum blancher for continuous cooking and blanching

Optimize your production line with a continuous drum blancher, designe...

Belt blancher for vegetables

Optimize your vegetable processing with efficient blanching and cooking, ensuring reduced treat...

Fruit and vegetable washing solution with agitating action

Experience efficient dirt removal and product agitation for f...

Horizontal mixer for creams

Achieve optimal and uniform mixing of creams, pasty products, and powders with advanced horizont...

Vertical mixer for creams and desserts

Achieve uniform mixing and precise temperature control for diverse creamy and liquid...

Vertical bowl for cooking, degassing, and concentration of fruits and vegetables

Optimize the cooking, degassing, and ...

Turbo mixer for homogeneous solutions in food and pharmaceutical industries

Effortlessly achieve uniform suspensions a...

Sterile cooling system for fruit preparations

For manufacturers seeking aseptic conditions, this cooling system ensures ra...

High-pressure homogenizer for dairy and food production

Optimize your product consistency and stability with a high-press...

Industrial homogenizers for high-pressure applications

Optimize homogenization with high-pressure solutions designed for ...

Bakery spraying system for accurate liquid application

Achieve precise and consistent liquid application across diverse c...

Inline ultrasonic slicer for bakeries

Achieve consistent precision in high-speed food portioning with this cutting-edge sli...

Ultrasonic slicer for cakes and pastries

Achieve precision cuts and superior presentation with this ultrasonic slicer, desi...

Depositing solutions for liquid and semi-liquid foods

Ensure consistent portioning and minimize waste with advanced depos...

Ultrasonic cutter for pastry and bakery products

Achieve precise, high-quality cuts for your bakery and confectionery prod...

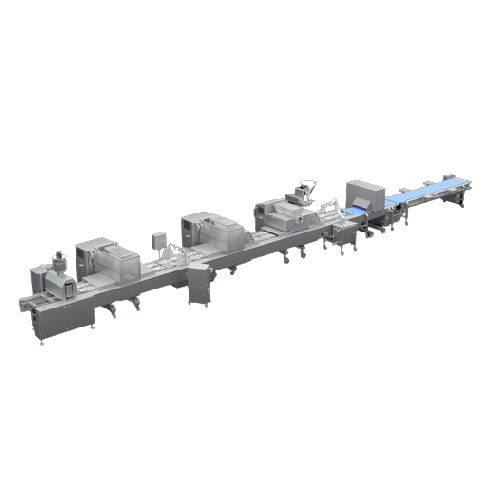

Production line for round and square cakes

Streamline your bakery operations with a modular cake production line designed ...

Depositing line for cake production with paper cup denester

Optimize your cake production by seamlessly depositing marbl...

Industrial glazing line for high-volume production

Elevate your production efficiency with this robust glazing line, opti...

Multifunctional depositing line for bakery production

Optimize your bakery and food production with a modular depositing ...

Multifunctional dessert line for layered dessert production

Effortlessly create complex, multi-layer desserts or meal co...

High-volume spraying system for glazes and marmelades

Streamline your glazing process with a system designed to minimize ...

Egg wash disc sprayer for bakery finishing

Achieve precise liquid application with minimal waste using this disc sprayer, ...

Table top depositor for semi-liquid and solid products

Streamline your bakery operations with a compact solution engineer...

Efficient topping strewer for bakery production lines

Enhance your product’s appeal and streamline topping applicat...

Industrial cream whipping machine

Elevate your production with a whipping machine that amplifies cream volume by up to 50%,...

Cake batter depositing line

Streamline your production with precise batter depositing and greasing, minimizing waste and opt...

Full production greasing and depositing line for bakery products

Elevate your production process with a greasing and dep...

Industrial mixer for liquid and viscous products

Achieve precise mixing and homogenization of high-viscosity liquids and s...

Vacuum mixer for liquids and semi-solids

Achieve precise mixing and homogenization of liquid and semi-solid formulations wi...

Cip system for process tanks

Ensure high-level cleanliness and compliance in your production line with an efficient in-place...

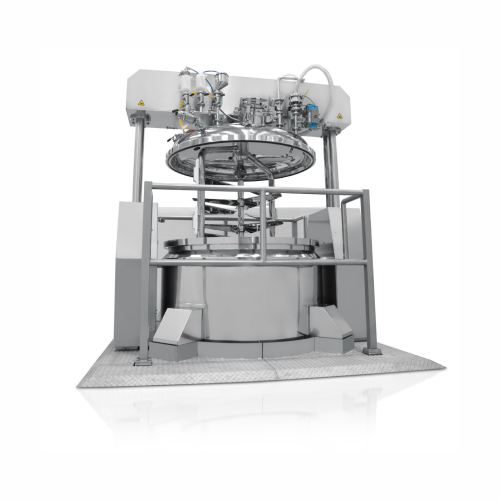

Vacuum homogenizer for high-quality mixing and emulsification

Achieve optimal consistency and enhanced product stability...

Industrial under vacuum homogenizer

Optimize your batch production with an under-vacuum homogenizer that ensures precise mi...

Industrial under vacuum homogenizer

Optimize the consistency and texture of creams and lotions with precision-controlled mi...

Vacuum homogenizer for creams and ointments

Streamline your production with cutting-edge vacuum homogenization, perfect fo...

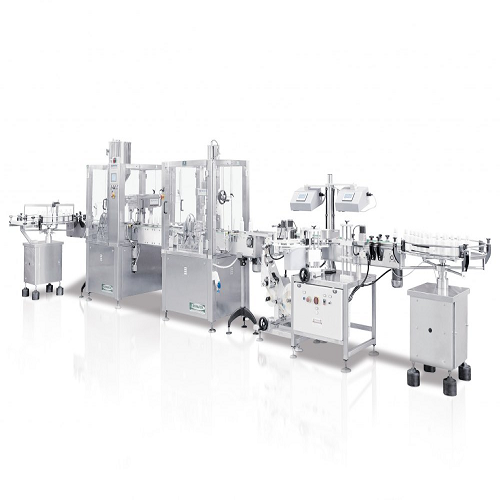

Automatic bottle filling and capping line

Streamline your liquid product packaging with this high-speed solution, integrat...

Pneumatic dosing system for dense and semi-dense products

Easily handle dense and semi-dense products with precision dos...

Cip clean-in-place system for undervacuum homogenizers

Ensure seamless sanitation for your undervacuum homogenizers with ...

Linear filler for preformed containers

Streamline your packaging process with a compact solution that ensures precise filli...

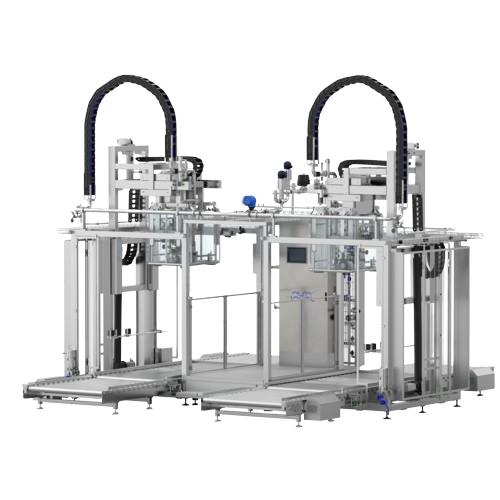

Aseptic cooking and filling line with two reactors

Streamline your production with a versatile line that combines high-ef...

Thousand-litre aseptic filler

Ensure the aseptic filling of bulk liquid and viscous food products, reducing contamination ri...

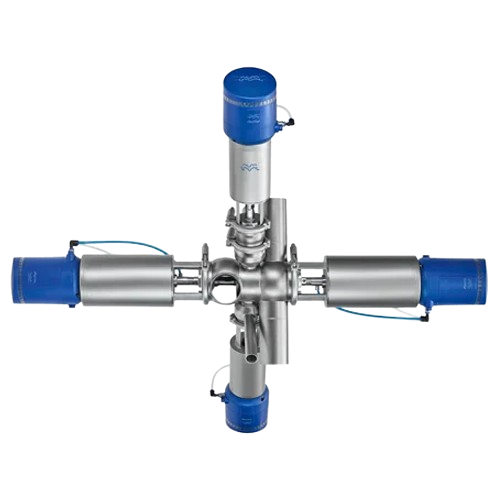

Aseptic mixproof valve for sterile processing

Ensure absolute product safety and optimize cleaning efficiency in sterile p...

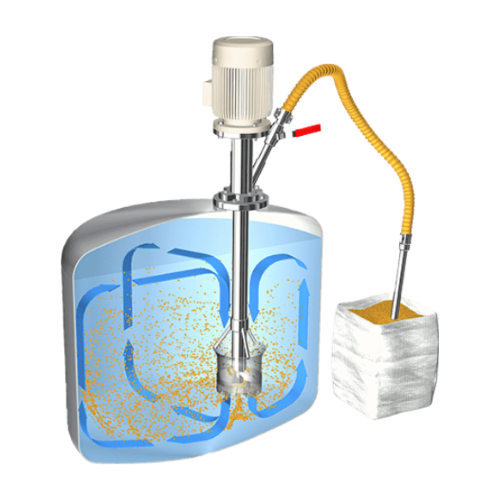

Automated powder induction and dispersion system for industrial mixing

Achieve rapid and efficient incorporation of pow...

Pilot scale mixers for product development and small production runs

Optimize your mixing processes with precision cont...

High precision automatic mini dose filler

Achieve unparalleled precision when filling small volumes, from 0.1 ML to 200 ML...

Rotary volumetric filling solution for viscous products

Achieve precision in volumetric filling with a machine designed f...

Automatic positive displacement bottle filler

Streamline your liquid filling operations with precision and flexibility, id...

Accurate net weight filling for liquid and semi-liquid products

Ensure precise filling of diverse viscosities, from thin...

Semi-automatic piston injector for bakery products

Enhance your bakery production with precise delivery of a wide range o...

Auto bakery tray depositor for creams and batters

Efficiently deposit precise quantities of creams and batters with high-...

Industrial mixing tanks for liquid, slurry, and gas dosing

Optimize your production with versatile mix tanks, designed t...

Industrial homogenizer for Uht sterilization systems

Achieve smoother product consistency with high-pressure homogenizati...

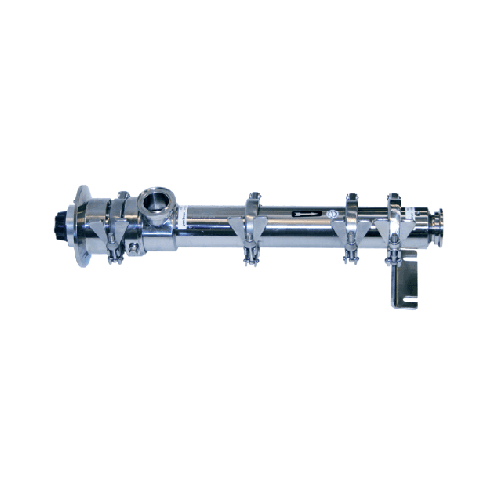

3a certified product recovery system for food and pharmaceuticals

Optimize your production line with a system designed ...

Hygienic pump for beverage and pharmaceutical industries

Engineered to meet stringent hygiene demands, this versatile pum...

High shear mixer for dairy and personal care products

Achieve consistent emulsification and stable homogeneity with high ...

High shear test mixers for developing new products

Streamline product development with high shear test mixers, allowing y...

Very high pressure homogenizer compression block

Experience reliable performance at extreme pressures with a compression b...

High pressure industrial homogenizer

Enhance liquid formulations with precision and efficiency—our high-pressure homogenize...

Rotary piston fillers for pumpable products

Optimize high-speed production lines with precision filling for diverse liquid...

Rotary piston fillers with plunger for viscous products

Optimize your filling process with high-speed, rotary piston fill...

Low-dust powder induction mixer for liquids

Achieve dust-free induction and homogenization of powders in liquids with prec...

X-ray scanner for contaminant detection in packaging

Ensure your products remain contamination-free with advanced X-ray s...

Industrial sigma mixer extruder for homogeneous mixing and extrusion

Achieve precise mixing and seamless extrusion of d...

Laboratory mixers for product development and research

Optimize your R&D efforts with advanced mixing solutions desi...

Industrial mixers for hire

Optimize your production line with versatile mixers designed for precision blending, heating, and...

Shaftless spiral conveyor for waste water treatment

Efficiently handle challenging materials like de-watered sludge and s...

Planetary mixers for baking and food industries

Achieve precise mixing and consistency across a range of products with adv...

Planetary mixer for bakery and catering

Streamline your baking operations with a planetary mixer designed for precision mix...

Adjustable industrial mixers for thick product blending

Experience precise blending and control for thick and high-viscos...

Vacuum homogenizers for cosmeto-pharma and fine chemistry

Bring precision and efficiency to your formulation processes w...

Vacuum homogenizer for cosmeto-pharma applications

Optimize your formulations with our vacuum homogenizers, ensuring prec...

Vacuum homogenizer for cosmetics and pharmaceuticals

Optimize your production with precision mixing and homogenizing, ess...

Dosing pump for liquids and pastes

Achieve precise dosing and filling of liquids and pastes with flexibility in dosing volu...

Industrial fluid and paste preparation system

Eliminate air bubbles and achieve uniform viscosity in fluids and pastes to ...

Dosing and filling pump for liquids and pastes

Achieve precise dosing and filling of liquids and pastes with compact, hygi...

Dosing and filling pump for hygienic applications

Optimize your production line with this dosing and filling pump, design...

Industrial mixer for product-critical processes

When dealing with high-hygiene requirements and complex mixing tasks acros...

Complete mixing systems for industrial applications

Optimize your production efficiency and product consistency with adva...

Complete mixing solutions for food, chemical, and cosmetic industries

Enhance your production line with precision mixin...

Complete mixing solution for food, cosmetics, and chemical industries

Optimize your production line with a system that ...

Viscous and liquid product processor

Optimize your production of viscous slurries and liquid formulations with a versatile ...

Gmp contact part washers for pharmaceutical industry

Ensure product integrity and hygiene with specialized washing system...

High speed pneumatic depositor for bakery applications

When depositing batters, creams, and sauces, achieving consistent ...

Food transfer and dosing pumps for bakeries

Enhance efficiency in food processing with pumps designed for precise transfer...

Parfait production line equipment

Optimize your dessert production with advanced depositing technology, perfect for creatin...

Pneumatic depositor for bakery batters and fillings

Perfect for high-speed bakeries aiming to enhance efficiency, this se...

Portable table top bakery depositor

Optimize your baked goods production with precise portioning and rapid depositing, all ...

Pneumatic Rp depositor for bakery and food plants

Optimize your production line with a high-speed depositor designed to d...

Sanitary vessels for pharmaceutical applications

Ensuring the highest standards of aseptic processing, these sanitary vess...

Aseptic filler for fruit juice and dairy products

Ensure sterile, high-speed filling of liquids and creams with precision...

Aseptic filler for various liquid and semi-liquid food products

For manufacturers focused on quality, this aseptic filli...

Aseptic filler for fruit juice and puree

Ensure optimal product safety and quality with this aseptic filler, designed to ha...

Aseptic filling solution for fruit juice and dairy products

Ensure product integrity and safety with this aseptic fillin...

Semi-automatic filling and closing system for pre-formed containers

Streamline your packaging process with reliable sem...

Commercial cooking kettles for cook-and-chill food production

Transform your cook-and-chill processes with kettles that ...

Automatic tube filler for multi-color coextruded products

Achieve precise dual- or tri-color product designs with except...

Automatic tube filling solution for high-volume production

Effortlessly streamline your production with this high-speed ...

Turbo emulsifier for creams, gels, toothpastes

Achieve perfect emulsification and homogenization for your creams, gels, an...

Small batch tube filling system for metal and plastic tubes

Optimize your small-batch production with precise tube filli...

Volumetric piston fillers for liquid and dense products

Perfect for diverse packaging needs, these volumetric piston fill...

Manual monoblock for filling and capping jars

Optimize your jar filling and capping processes, even with high-temperature ...

Accurate volumetric filler for liquid and semi-dense products

Achieve precise dosing and filling of various liquid and s...

Bench-top piston filler for liquid and semi-dense products

Optimize your filling precision with a versatile piston fille...

Automatic line for filling and capping spouted pouches

Streamline your production line with high-speed filling and cappin...

Dry and liquid ingredient batch mixer for bakery applications

Achieve homogeneous mixing with precise heat control and e...

Compact continuous aerator for bakery production

Optimize your bakery production with a compact aerator that delivers prec...

Medium torque top entering mixer for chemical processing

Achieve consistent mixing results with a versatile, high-torque ...

High pressure homogenization system for dairy and creams

Optimize your high-speed homogenization processes with precise c...

High pressure homogenizer for dairy and pharmaceutical industries

When uniform texture and stable emulsions are critica...

Pilot plant homogenizer for immiscible liquids

Streamline your R&D with precise homogenization, allowing you to test ...

Semi-automatic tablet hardness tester

Optimize your tablet production with precise and reliable testing of hardness, dimens...

Tapped density tester for pharmaceutical powders

Ensure precise quality control in pharmaceuticals by accurately measuring...

Automated weighing system for tablets

Ensure precision in pharmaceutical manufacturing by seamlessly integrating advanced w...

Automated sample preparation workstation for lab efficiency

Streamline laboratory operations by automating sample prepar...

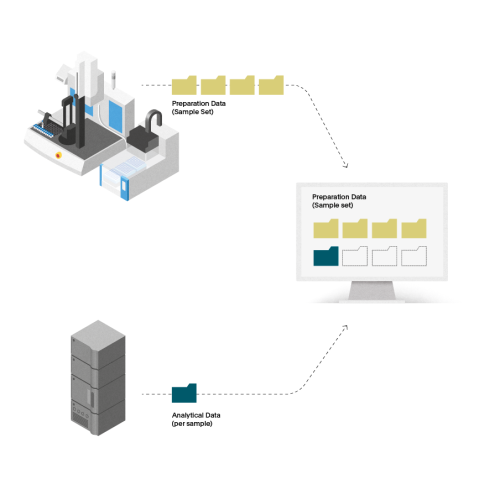

Automated sample preparation workstation for content uniformity testing

Streamline your laboratory workflows with autom...

Automated sample preparation software for pharmaceutical testing

Streamline your laboratory’s sample preparation w...

Dissolution medium preparation system

Streamline your laboratory workflows with a system that prepares and manages dissolut...

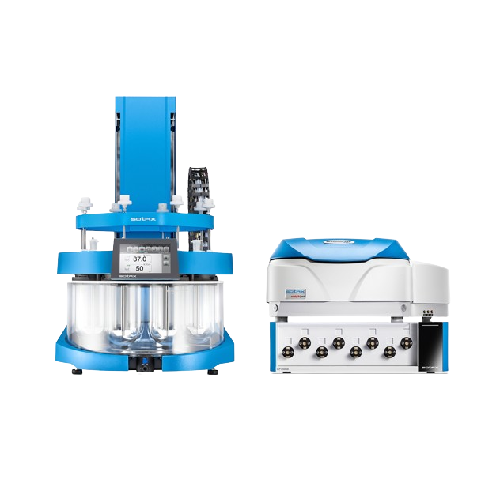

Automated flow-through cell dissolution testing system

Enhance precision in dissolution testing with real-time UV-Vis ana...

Flow-through cell dissolution testing with Uv analysis

Effortlessly monitor real-time dissolution with flow-through cell ...

Motorized cap torque tester for bottle closures

Ensure precise seal integrity and compliance with bottle cap torque measur...

Bathless disintegration apparatus for tablet and capsule testing

Achieve rapid and precise disintegration testing of tab...

Manual tablet disintegration tester

Ensure precise and reliable disintegration testing of pharmaceutical tablets, capsules,...

Tablet friability tester

Ensure your tablets meet rigorous quality standards by accurately measuring friability and abrasion,...

Powder flow tester for pharmaceutical powder flowability

Quickly assess powder flow characteristics to ensure consistent ...

Multi-parameter tablet hardness tester for laboratories

Optimize your tablet production line with a versatile tester that...

Advanced dissolution tester for pharmaceutical laboratories

Achieve consistent and reproducible dissolution results with...

Manual dissolution tester for pharmaceutical applications

Achieve precise and repeatable sampling in pharmaceutical test...

Automated dissolution sample collection system

Double your testing efficiency with parallel dissolution sampling, ensuring...

Automated dissolution testing with direct Hplc injection

Streamline your lab operations with precise and efficient direct...

Integrated Uv-vis spectrophotometer for dissolution testing

Streamline your dissolution testing with real-time UV-Vis an...

Real-time Uv-vis analysis for dissolution testing

Efficiently perform dual dissolution tests simultaneously, seamlessly i...

Automated dissolution testing system for 16 vessels

Maximize your laboratory throughput by conducting parallel dissolutio...

Dissolution testing software for automated analysis

Streamline your laboratory testing with seamless data capture and in-...

Dissolution testing software for pharmaceutical industry

Optimize dissolution testing with advanced software that manages...

Automated sample preparation software

Enhance your laboratory’s efficiency with a software solution that automates sa...

Benchtop dissolution tester for multiple test runs

Streamline your laboratory’s workflow with a fully automated ben...

Self-cleaning dissolution tester for automated series testing

Achieve unparalleled precision in dissolution testing with...

Pilot plants for small-scale viscous product processing

Optimize your product development with pilot plants designed for ...

Buffer tanks for high viscosity fluids

Optimize your production line with buffer tanks designed to efficiently store, agita...

Industrial fat melter for food and pharma applications

Optimize your production line with an advanced solution designed t...

Laboratory in-line mixer for precise mixing and reproducibility

Achieve precise laboratory-scale mixing with rapid proce...

Homogenizers for creams and ointments

Achieve superior consistency and particle size reduction in skincare creams, sauces, ...

High shear inline mixer for continuous processing

Effortlessly streamline your mixing process with this solution capable ...

Dried nuts roasting system

Efficiently transform raw dried nuts into high-quality pastes and creams, optimizing flavor and t...

Bean to bar chocolate production equipment

Transform cocoa beans into exquisite single-origin chocolate with complete cont...