Automated dissolution testing system for 16 vessels

Maximize your laboratory throughput by conducting parallel dissolution tests with high-precision UV-Vis analysis, ensuring real-time results and compliance for complex pharmaceutical formulations.

Automates and Analyzes Pharmaceutical Dissolution Testing

The ATS Xtend™ Double UV On-/Offline Dissolution Tester from SOTAX offers an innovative solution for laboratories needing efficient dissolution testing of pharmaceutical and biotech formulations. This system is capable of automating dissolution analysis for up to 16 vessels simultaneously, utilizing high-precision double beam UV-Vis technology for accurate and reliable results. Its standout feature is the ability to alternate between online testing and offline sample collection with minimal system adjustments, enhancing flexibility.

Ideal for analyzing tablets, capsules, injectable suspensions, and other complex drug forms, it supports high-throughput operations to meet demanding production schedules. The Xtend™ system includes robust integration capabilities, sharing a single UV-Vis spectrophotometer and dual-rack sample collector across two dissolution baths, minimizing both financial investment and spatial requirements.

Configured with fully compliant systems that adhere to Pharmacopeia standards and 21 CFR part 11, it ensures stringent regulatory compliance. The equipment’s sampling flexibility, through various filtration methods, optimizes preparation for downstream HPLC/UPLC analysis, while the media and filter stations facilitate precise and efficient media preparation and filtration.

Engineered to reduce variability and improve productivity, the Xtend™ series supports scalable laboratory needs by simplifying the addition of modules without excessive validation requirements. Its compact design allows for easy cleaning and maintenance, further establishing it as an essential tool for pharmaceutical manufacturers and research institutions.

Benefits

- Increases productivity with simultaneous testing from up to 16 vessels, enhancing workflow efficiency.

- Minimizes system modifications with online-to-offline testing flexibility, saving time and resources.

- Ensures data integrity and compliance with integrated regulatory adherence and comprehensive documentation.

- Reduces equipment footprint while maximizing utility by utilizing a shared UV-Vis and sample collector system.

- Supports diverse analytical requirements with adaptable filtration options for various pharmaceutical processes.

- Applications

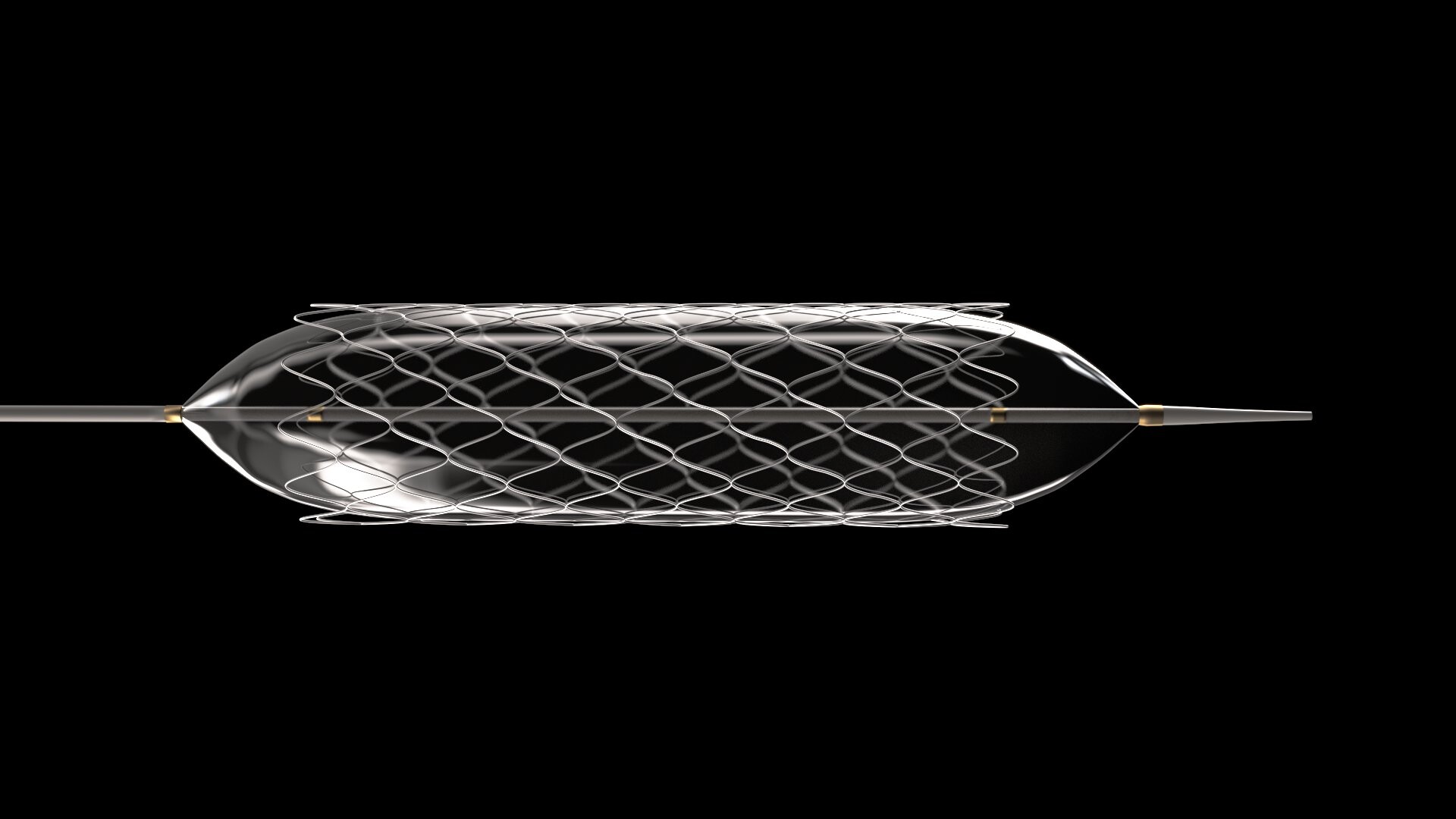

- Medical devices, Gels, Pellets, Granules, Microspheres, Catalysts, Stents, Food, Pharmaceutical tablets, Nano suspensions, Fine chemicals, Coated lenses, Soft-gelatin capsules, Implants, Api's, Animal health, Capsules, Washtabs, Transdermal patches, Creams, Suppositories, Semi-solids, Powders, Injectable suspensions

- End products

- Zinc oxide nano suspensions, Vitamin e capsules, Anti-reflective coated lenses, Omeprazole pellets, Protein powder, Insulin injectable solution, Hydrocortisone cream, Doxycycline microspheres, Paracetamol tablets, Zeolite catalyst, Bone implants, Animal health vaccinations, Glycerin suppositories, Dishwasher tablets, Fish oil soft-gelatin capsules, Aloe vera gel, Ethanol fine chemical, Lidocaine topical patch, Coronary stents, Fortified pet food, Instant coffee granules, Ibuprofen active pharmaceutical ingredient (api)

- Steps before

- Media Preparation, Degassing, Heating

- Steps after

- Filtration, HPLC/UPLC Analysis, Data Reporting, Cleaning

- Input ingredients

- dissolution samples, tablets, capsules, pellets, APIs, powders, granules, soft-gelatin capsules, suppositories, medical devices, stents, implants, microspheres, nano suspensions, injectable suspensions, semi-solids, gels, creams, transdermal patches, washtabs, fine chemicals, catalysts, food, animal health products, coated lenses, bottles with screwcaps

- Output ingredients

- analyzed dissolution results, filtered samples, glass tubes with samples, capped LC vials, well plates with samples, real-time data, UV-Vis analysis results, HPLC/UPLC ready samples

- Market info

- Sotax AG is renowned for its expertise in manufacturing high-quality pharmaceutical testing equipment, including dissolution testing systems, and has a strong reputation for reliability, precision, and innovation in laboratory and industrial applications.

- Automation

- Fully automated

- Capacity

- Up to 16 vessels

- Filtration

- Cannula filters, disc filters, syringe filters

- Precision

- High-precision double beam UV-Vis technology

- Footprint

- Stacking to minimize space

- Sample Collection

- Glass tubes, capped LC vials, well plates

- Compliance

- 21 CFR part 11

- Throughput

- Double capacity for parallel dissolution tests

- Automation level

- Repeatably automated

- Batch vs. continuous operation

- Parallel batch

- Cleaning method

- Automated filtration

- Energy efficiency

- Minimal footprint

- Scale-up capability

- Simplified by stacking modules

- Sample handling method

- Online and offline collection

- Sampling capability

- Up to 16 vessels simultaneously

- Space utilization

- Stacked modular design

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Pharmacopeia compliance

- USP

- Machine footprint

- Compact, stackable modules to minimize space

- Vessel capacity

- 16 vessels

- Control panel type

- Integrated with WinSOTAX®plus software

- Discharge method

- Automated sample collection in glass tubes, capped LC vials, or well plates

- Filtration system

- Automated with cannula filters, disc filters, and syringe filters

- Sample Collection

- Offline collection in glass tubes, LC vials, or well plates

- Space Optimization

- Stackable design