Industrial homogenizer for Uht sterilization systems

Achieve smoother product consistency with high-pressure homogenization, crucial for reducing particle size and ensuring even distribution in liquid products, essential in high-demand UHT processing environments.

Homogenizes and Sterilizes Liquid Products

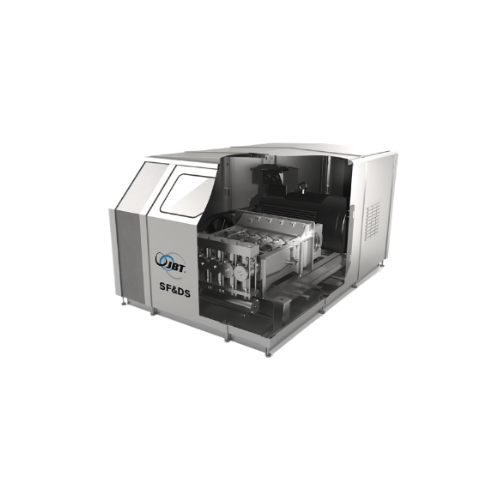

The SF&DS Homogenizer is a versatile high-pressure pump designed for use in ultra-high temperature (UHT) sterilization systems, serving the dairy, beverage, and food processing industries. This equipment efficiently homogenizes and sterilizes products like UHT milk, juices, creams, and purees, enhancing texture uniformity by using a two-head design to break down and evenly distribute fat particles. Capable of continuous, aseptic operation, it integrates smoothly with existing production lines and supports high-pressure processing for large-scale applications. Constructed for durability, it promises a long operational life with minimal maintenance, while its aseptic configuration ensures compliance with stringent hygiene standards. Customizable features and engineering support ensure it meets specific production requirements.

Benefits

- Enhances product consistency by ensuring uniform particle distribution.

- Lowers operational costs through minimal maintenance requirements.

- Increases production efficiency with continuous, high-pressure processing.

- Complies with stringent hygiene standards due to aseptic configuration.

- Offers flexible integration into diverse production lines with customizable options.

- Applications

- Beverages, Tomato processing, Dairy alternatives, Uht flavored milk, Uht white milk, Juices, Vegetable processing, Creams, Dairy, Fruit

- End products

- Chocolate flavored milk, Double cream, Pureed peaches, Skim milk powder, Ultra-high temperature treated whole milk, Orange juice, Almond milk, Energy drinks, Diced tomatoes

- Steps before

- UHT Sterilization, Aseptic Processing, Deaeration

- Steps after

- Packaging, Aseptic Filling, Sterilization

- Input ingredients

- milk, flavored milk, cream, juices

- Output ingredients

- homogenized milk, homogenized flavored milk, homogenized cream, homogenized juices

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Pressure

- High-pressure

- Configuration

- Aseptic

- Head

- One or two heads

- Maintenance

- Minimal

- Lifespan

- Long, economical

- Adjustability

- Versatile and easily adjustable

- Application

- UHT Sterilization

- Use Cases

- UHT milk, creams, juices

- Working mechanism

- High-pressure pump

- Integrated steps

- Fat droplet size reduction

- Automation level

- Manual / PLC

- Batch vs. continuous operation

- Continuous

- CIP/SIP

- CIP

- Cleaning method

- CIP

- Product Uniformity

- Achieved by fat droplet size reduction

- Product Types

- UHT milk, creams, juices

- Discharge method

- Narrow opening discharge

- Machine configuration

- Aseptic

- Head configuration

- One or two heads

- Control panel type

- Manual / PLC / HMI

- Integration possibilities

- SCADA / MES

- Head configuration

- Single or Double

- Pressure adjustment

- High pressure, adjustable

- Aseptic configuration

- Available