Industrial homogenizers for high-pressure applications

Optimize homogenization with high-pressure solutions designed for precise control and consistent quality in complex liquid and slurry formulations.

Processes and Homogenizes Liquids and Slurries

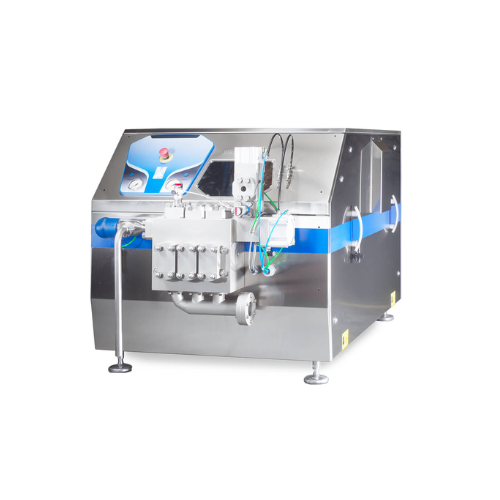

The HA32-SM High Pressure Homogenizer from Bertoli Homogenizers integrates seamlessly into your production line, tackling homogenization and dispersion challenges in industries such as food and beverage, pharmaceuticals, and cosmetics. Utilizing a robust multi-stage homogenizing process, it ensures consistent particle size distribution, crucial for end products like nanoemulsions and dairy emulsions. With a capacity of up to 800 l/h at pressures reaching 1,500 bar, and powered by a 30 kW motor, this unit supports both liquid and slurry processing under continuous high-pressure conditions. Engineered with integral carbide plungers and hygienically designed to extend maintenance cycles in accordance with MOCA, it ensures durability and ease of maintenance. Equipped with poppet valves, it effectively handles viscous and abrasive materials, making it highly adaptable across applications. The system’s low water consumption and silent operation reduce operational costs while maintaining a sustainable footprint. Customization options and engineering support are available to tailor the equipment to specific requirements, making it an ideal choice for high-demand processing environments.

Benefits

- Enhances product consistency by achieving uniform particle distribution across a wide range of applications.

- Lowers maintenance costs with a durable design featuring integral carbide plungers and poppet valves.

- Minimizes operational expenses with efficient energy usage and low water consumption.

- Ensures compliance with hygiene standards, extending maintenance intervals in critical environments.

- Adapts to various industrial needs with support for viscous and abrasive materials.

- Applications

- Pharma and biotech, Cosmetic, Chemical and nano dispersion, Food and beverage, Dairy

- End products

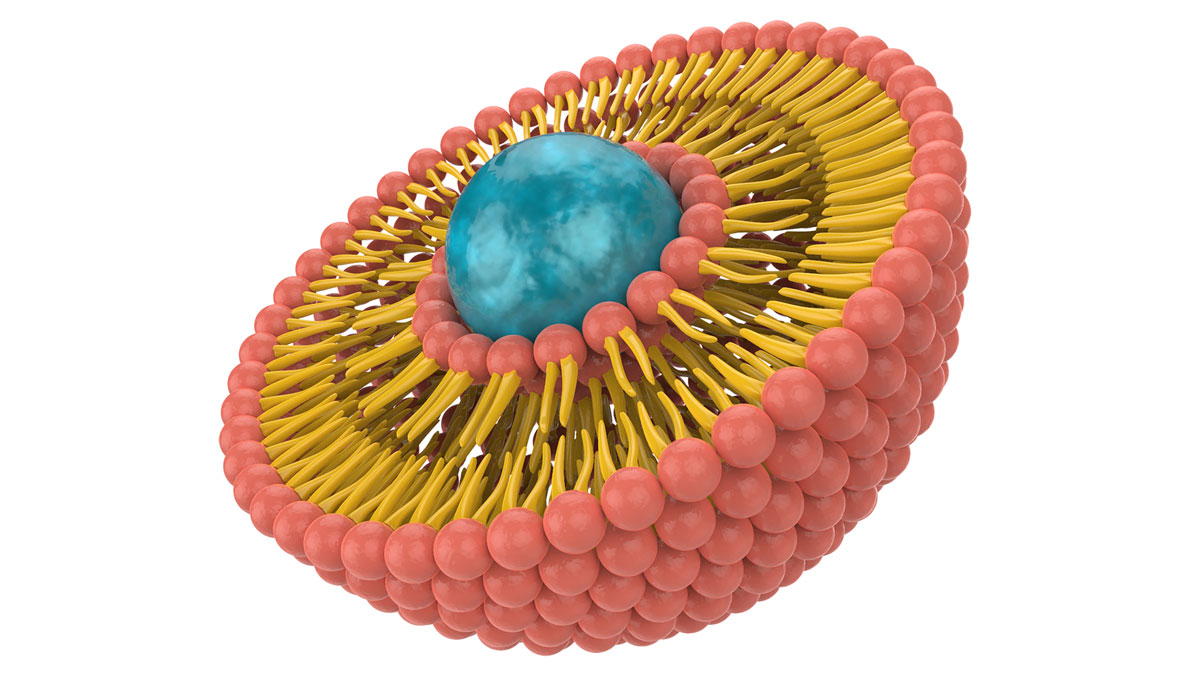

- Sauces, Liposomes, Syringes, Vaccines, Milk, Salad dressings, Facial creams, Fruit juices, Mayonnaise, Cheese, Yogurt, Nano emulsions, Foundation, Creams

- Steps before

- Emulsification, Mixing, Pre-heating

- Steps after

- Sterilization, Packaging, Cooling

- Input ingredients

- viscous products, abrasive products

- Output ingredients

- homogenized liquid, nanodispersed chemicals, food and beverage products, pharmaceutical emulsions, cosmetic mixtures, dairy products

- Market info

- Bertoli, part of the Interpump Group, is known for its expertise in designing and manufacturing high-pressure homogenizers and positive displacement pumps, serving industries like food processing, pharmaceuticals, and cosmetics, with a reputation for reliability and innovation.

- Power

- 30 kW

- Pressure

- 1, 500 bar at 400 l/h

- Capacity

- 800 l/h at 1, 000 bar

- Plunger number

- 3

- Stroke

- 70 mm

- Weight

- 1, 400 Kg

- Water consumption

- 150 l/h

- Lubrication oil quantity

- 10.5 kg

- Product inlet/outlet

- 1" GAS / 1" GAS

- Working Pressure

- Up to 1500 bar

- Flow Rate

- Up to 800 l/h at 1000 bar

- Plunger Count

- 3

- Energy Efficiency

- 30 kW

- Cooling Method

- Water Cooled

- Maintenance Accessibility

- Easy Open Panels

- Hygienic Design

- MOCA Compliant

- Noise Level

- Silent equipment

- Water Consumption

- 150 l/h

- Batch vs. Continuous Operation

- Continuous

- Lubrication System

- 10.5 kg Oil

- Product Inlet/Outlet

- 1” GAS

- Abrasion resistance

- High

- Biological compatibility

- Food grade

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Cleanability

- CIP-compatible

- Density/particle size

- Adaptable to various product densities

- Control panel type

- HMI/PLC interface

- Integration possibilities

- SCADA/IoT ready

- Discharge method

- Easy-open panels

- Hygienic design

- MOCA compliant

- Maintenance features

- Extended maintenance intervals

- Plunger material

- Integral carbide

- Valve type

- Poppet valves

- Transmission system

- Low maintenance cost