Multi-parameter tablet hardness tester for laboratories

Optimize your tablet production line with a versatile tester that ensures precision across multiple parameters, including weight, thickness, and hardness, seamlessly integrating with your laboratory workflow to enhance quality control.

Measures and Aligns Tablets with Precision

The AT50 from SOTAX is a versatile tablet hardness tester designed for precise, multi-parameter testing in pharmaceutical environments. Utilizing Dr. Schleuniger® technology, it handles diverse tablet shapes for weight, thickness, width, length, and hardness assessment. The AT50 is commonly used in the production of tablets like paracetamol and Ibuprofen, aligning with in-process control (IPC) and quality control (QC) requirements.

The AT50 integrates seamlessly into existing laboratory setups or online with tablet presses for continuous, automated testing and calibration. Its compact design features patented AutoAlign™ and SmartAlign™ technologies to ensure accurate tablet positioning, while its universal high-speed feeder expertly manages separation and weighing. The AT50 is CIP-compatible for easy maintenance and features an IP52 protected test area for straightforward cleaning.

With dynamic qualification tools like DQD™ for tablet hardness verification and a built-in Mettler Toledo balance for accuracy checks, the AT50 supports compliance with 21 CFR part 11 and offers full data management through q-doc® software. Available in materials suitable for pharmaceutical standards, this unit is engineered for reliability and adaptability in complex testing scenarios.

Benefits

- Ensures consistent quality control with precise multi-parameter testing for various tablet forms.

- Minimizes operator intervention through integrated online connectivity with tablet presses.

- Guarantees data integrity and regulatory compliance with 21 CFR part 11 requirements.

- Enhances testing efficiency with continuous operation and easy sample loading via SmartAdd™.

- Maintains clean working conditions with an IP52 protected test area and DustX™ brake cyclone.

- Applications

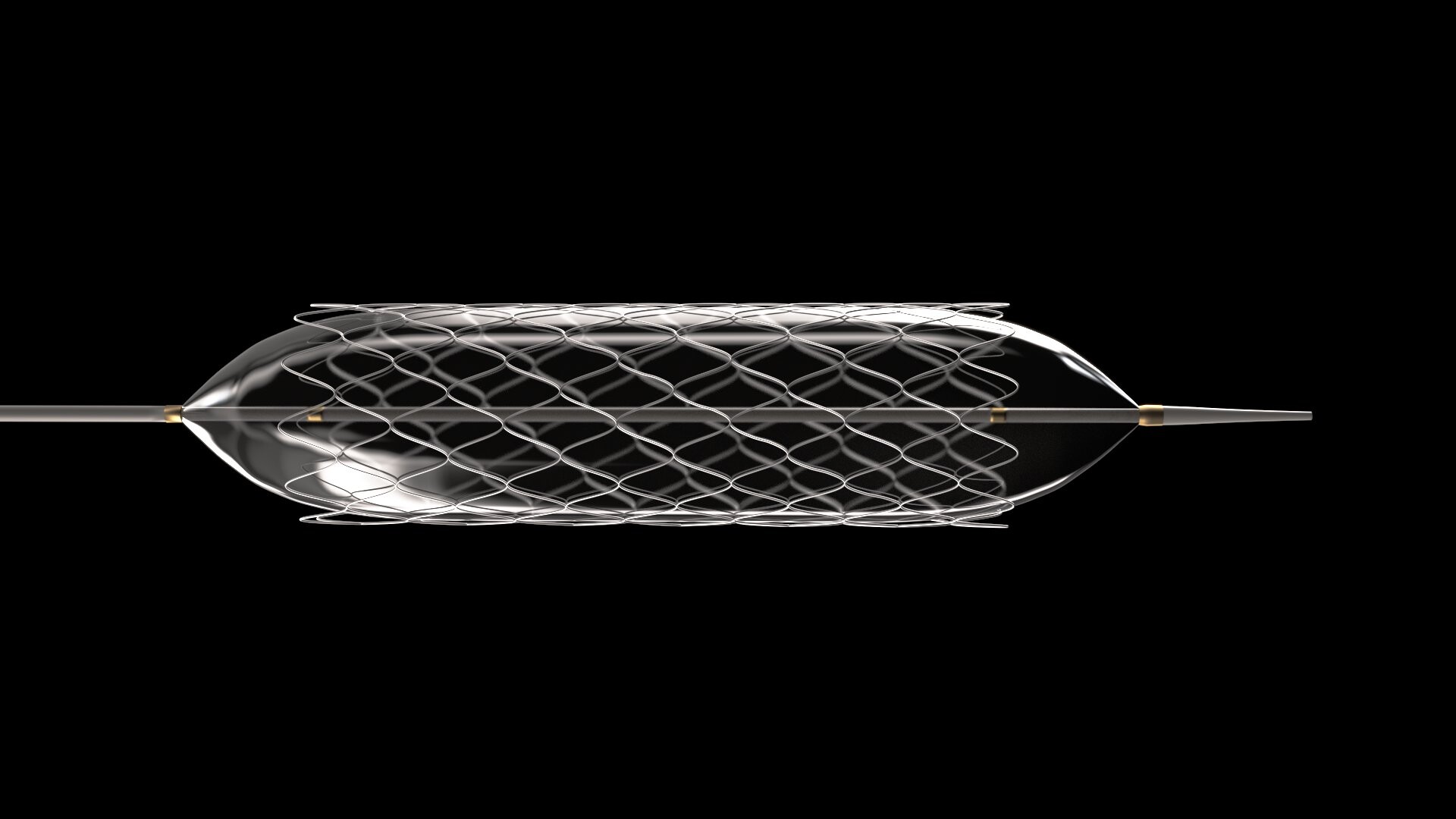

- Medical devices, Gels, Pellets, Granules, Microspheres, Catalysts, Stents, Pharmaceutical tablets, Nano suspensions, Fine chemicals, Soft-gelatin capsules, Implants, Api's, Capsules, Washtabs, Transdermal patches, Creams, Suppositories, Semi-solids, Powders, Injectable suspensions

- End products

- Omeprazole pellets, Insulin injectable suspensions, Silicone fine chemicals, Hydrocortisone creams, Liposomal nano suspensions, Glycerin suppositories, Hip implants, Dishwashing washtabs, Nicotine transdermal patches, Polymeric microspheres, Fish oil soft-gel capsules, Fertilizer granules, Ibuprofen capsules, Metformin apis, Protein powder supplements, Coronary stents, Zeolite catalysts, Paracetamol tablets, Lidocaine gels

- Steps before

- Tablet Pressing, Powder Blending, Granulation

- Steps after

- Coating, Packing, Sterilization

- Input ingredients

- tablets, oblongs, oval tablets, convex shapes, hexagonal tablets, round tablets, diamond-shaped tablets, almond-shaped tablets, triangular shapes, mini tabs, soft-gelatin capsules, medical devices, microspheres, injectable suspensions, semi-solids, transdermal patches, washtabs

- Output ingredients

- tested tablets, measured parameters, hardness results, weight measurements, thickness results, width measurements, length/diameter measurements, alignment data, compliance data, integrity data

- Market info

- Sotax AG is renowned for its expertise in manufacturing high-quality pharmaceutical testing equipment, including dissolution testing systems, and has a strong reputation for reliability, precision, and innovation in laboratory and industrial applications.

- Cycle time

- Very short

- Automation

- Automatic

- Compliance

- 21 CFR Part 11

- Accuracy

- Maximum precision

- Data management

- q-doc® software

- Product compatibility

- Multiple tablet shapes

- Cleaning method

- Easy cleaning, IP52 protected

- Precision tools

- DQD™ dynamic qualification tool

- Tablet alignment

- AutoAlign™, SmartAlign™

- Weight measurement

- Integrated weighing module

- Feeder system

- High-speed universal feeder

- Testing parameters

- Weight, thickness, width, length/diameter, hardness

- Automation level

- Fully Automated / Unattended

- Batch vs. continuous operation

- Batch / Inline Continuous

- Cleaning method

- Easy Cleaning / IP52 Protected

- Connectivity

- Online with Tablet Press

- Data Management

- 21 CFR part 11 Compliance

- Precision

- High-end Components

- Product Capacity

- Up to 10 Different Products

- Tablet Alignment

- AutoAlign™ / SmartAlign™ Technology

- Testing Parameters

- Weight, Thickness, Width, Length, Hardness

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Sample Type

- Tablets / Capsules / Powders

- Tablet Shape Compatibility

- Oblong / Oval / Hexagonal / Triangular / Convex

- Automation Level

- Manual / Automatic with AutoAlignTM and SmartAlignTM

- Machine footprint

- Benchtop

- Tablet shapes supported

- Oblong, diamond, almond, convex oval, hexagon, triangular

- Test area protection

- IP52

- Control interface

- TouchControl™ sensor

- Control panel type

- TouchControl™

- Tablet alignment technology

- AutoAlign™, SmartAlign™

- Integration possibilities

- Online connection with tablet press

- Feeder system

- SmartAdd™ magazine feeder

- Cleaning method

- IP52 protected, easy cleaning

- Data management software

- q-doc®