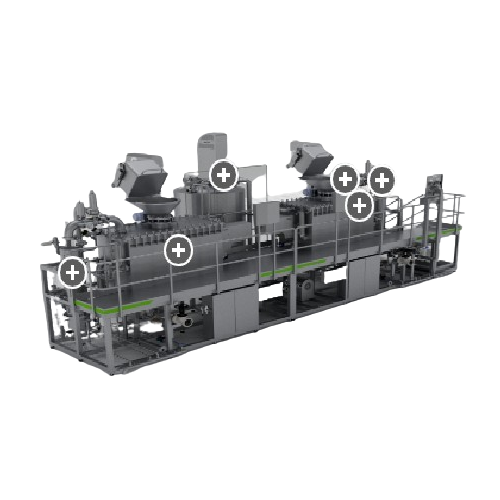

Aseptic cooking and filling line with two reactors

Streamline your production with a versatile line that combines high-efficiency cooking and reliable aseptic filling, reducing energy consumption and processing time for diverse food and cosmetic applications.

Processes Diverse Food Products with Efficiency

The Single Cooking Line with Dual T-Sensation Reactor Units from Aurum Process Technology revolutionizes food and body care production with its patented engineering. This horizontal, stainless steel reactor processes between 50 to over 1,000 liters, optimizing heat transfer via scraped-surface plates for faster throughput. Known for aseptic processing, it’s adept at handling diverse viscosities and particle sizes across applications like broths, sauces, and baby foods. The reactor integrates seamlessly into batch or continuous setups, leveraging high energy efficiency and minimal fouling. Without requiring pump feeding, it’s loaded through worm screw or bucket elevators, supporting pressurized or vacuum conditions. Perfect for food and beverage manufacturers, it promises high-quality outputs with low shearing, available with full customization and compliance with stringent industry standards.

Benefits

- Ensures high product quality by maintaining flavor and nutritional integrity.

- Minimizes processing time with efficient heat transfer, boosting throughput.

- Reduces operational costs with high energy efficiency and low fouling.

- Offers flexibility for various product viscosities and sizes, enhancing versatility.

- Streamlines integration with batch or continuous processes, optimizing production flow.

- Applications

- Sauces, Industrial vegetable processing, Broths, Convenience food, Vegetable creams, Body care, Industrial fruit processing, Infant food

- End products

- Vegetable broth, Frozen mixed vegetables, Creams and lotions, Chicken broth, Carrot soup, Baby food pouches, Pasta sauce, Baby fruit puree, Fruit concentrates, Ready-to-eat meals, Tomato sauce, Canned vegetables, Fruit puree, Vegetable soups

- Steps before

- Preparation, Ingredient Mixing, Pre-heating, Blanching

- Steps after

- Aseptic Filling, Cooling, Packaging, Storage

- Input ingredients

- broths, industrial fruit, vegetables, convenience food, sauces, vegetable creams, infant food, products of any viscosity, products with particles of variable sizes

- Output ingredients

- high-quality product, flavour, nutritional properties, processed products with maintained integrity

- Market info

- Aurum specializes in the design and manufacture of custom-engineered industrial equipment, known for their innovative solutions, high-quality craftsmanship, and reliable performance in complex projects, establishing a strong reputation in the ETO equipment market.

- Material

- Stainless steel

- Capacity

- 50 to 1000+ litres

- Processing conditions

- Pressurised / Vacuum

- Heat transfer efficiency

- Maximised by scraped surface

- Production type

- Batch or Continuous

- Product compatibility

- Variable viscosity and particle sizes

- Performance

- Tenfold over conventional reactors

- Cooling system

- Aseptic processing with direct cooling

- Application

- Aseptic processes, heating, crystallising, evaporating

- Loading method

- Worm screw / Chain or belt-type bucket elevators

- Automation level

- PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Cleaning method

- CIP / Manual

- Abrasion resistance

- High

- Biological compatibility

- Food-grade stainless steel

- Cleanability

- High, suitable for CIP systems

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- Variable sizes, viscosities

- Reactor Material

- Stainless steel

- Reactor Capacity

- 50–1000+ litres

- Reactor Shape

- Horizontal

- Scraping System

- Complete surface scraping

- Footprint Type

- Compact

- Service Fluid Flow

- Maximized heat transfer surface

- Control panel type

- PLC-controlled

- Integration possibilities

- SCADA / HMI

- Material of construction

- Stainless steel

- Batch vs. continuous operation

- Batch / Continuous

- Scraping system

- Superficial full scraping

- Pressurization capability

- Yes / No

- Vacuum operation capability

- Yes / No

- Loading method

- Worm screw / Chain or belt-type bucket elevator