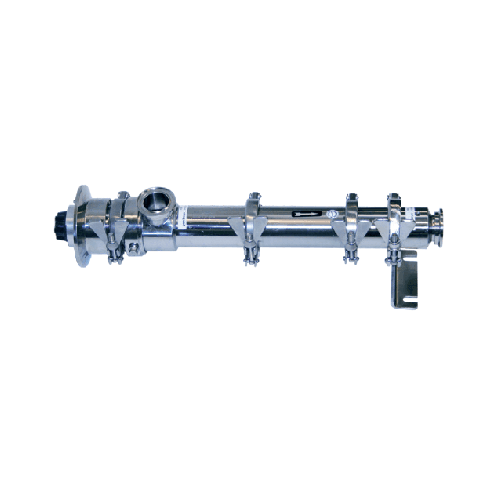

Dosing and filling pump for hygienic applications

Optimize your production line with this dosing and filling pump, designed to handle a wide range of viscosities and media types, offering precise volumetric control in processes ranging from barrel emptying to hot and cold filling.

Doses and Fills Viscous and Abrasive Media

The RD-hygienic dosing and filling pump from ViscoTec is designed for precise handling of viscous, abrasive, and shear-sensitive media across food, cosmetics, and pharmaceutical industries. Utilizing the endless piston principle, it ensures accurate dosing and consistent filling operations. Its adaptability to both hot and cold processes makes it suitable for applications like yogurt, foundation, and cough syrup production. With the capacity to convey and dose materials in continuous or manual operations, this pump integrates smoothly into pre-processing, processing, and final conditioning stages. It features options for double-walled design with heating medium supply and is actuated by a servo drive. FDA-compliant elastomers enhance its suitability for sensitive applications, ensuring compliance with industry standards, while CIP/SIP compatibility facilitates efficient cleaning. Custom engineering support and a variety of accessories further tailor the RD-hygienic pump to your specific process needs.

Benefits

- Enhances product quality by ensuring precise dosage and filling across varying viscosities and media types.

- Increases production efficiency with seamless integration into existing continuous and manual operations.

- Reduces operational costs with energy-efficient servo drive actuation and optional heating elements.

- Simplifies compliance management with FDA-quality elastomers and hygienic design suitable for CIP/SIP processes.

- Offers flexibility in processing conditions, accommodating both hot and cold filling requirements.

- Applications

- Food, Abrasive media, Hot and cold filling, Cosmetics, Shear sensitive media, Lumpy media, Pharmaceuticals

- End products

- Sauces, Gels, Cough syrup, Toothpaste, Hand cream, Ointments, Yogurt, Foundation, Creams

- Steps before

- Purification, Mixing, Emulsification

- Steps after

- Sterilization, Packing, Quality Control

- Input ingredients

- low viscosity media, high viscosity media, abrasive media, shear sensitive media, lumpy media, hot media, cold media

- Output ingredients

- dosed media, filled media, conveyed media

- Market info

- Visco Tec is known for its precision dispensing and dosing technology, specializing in equipment for viscoelastic fluids, offering reliable, high-quality solutions for industries like pharmaceuticals, food, cosmetics, and general manufacturing, renowned for engineering excellence and innovation.

- Dosing type

- Volumetric

- Filling method

- Volumetric / gravity

- Filling volume

- 1 ml – 5 L

- Viscosity range

- Low to high viscosity media

- Abrasiveness of material

- Yes

- Shear sensitivity

- Able to handle shear sensitive media

- Media temperature suitability

- Hot and cold filling

- Cleaning method

- CIP / SIP

- Hopper capacity

- 10 l or 50 l

- Material

- Stainless steel

- Heating option

- Double-walled design for heating medium

- Automation

- Servo drive actuation

- Pressure sensors

- Yes, for pump protection and control

- Working mechanism

- Endless piston principle

- Integrated steps

- Barrel emptying

- CIP/SIP

- Designed for optimal results

- Batch vs. continuous operation

- Batch / Inline Continuous

- Media viscosity range

- Low to high viscosity

- Temperature range

- Hot and cold filling

- Media compatibility

- Abrasive, shear sensitive, lumpy media

- Automation level

- Servo drive actuation

- Abrasion resistance

- Yes (Suited for abrasive media)

- Biological compatibility

- FDA quality elastomers available

- Cleanability

- Designed for CIP/SIP

- Corrosive resistance (e.g. acids)

- Special stainless steel available

- Shear sensitive media

- Yes (Suited for shear sensitive media)

- Viscosity range

- Low to high viscosity media

- FDA materials

- FKM, EPDM in FDA quality available

- Test report 3.1

- (DIN EN 10204)

- Discharge method

- volumetric

- Drum size

- 10 L / 50 L

- Heating medium supply

- Double walled design

- Elastomer material

- FKM, EPDM (FDA quality)

- Stainless steel options

- Special stainless steel on request

- Actuation type

- Servo drive

- Hopper size

- 10 L or 50 L

- Additional components

- Manifolds with air bleed valve

- Hose type

- Food or pharmaceutical hoses

- Pressure sensors

- For pump protection and control