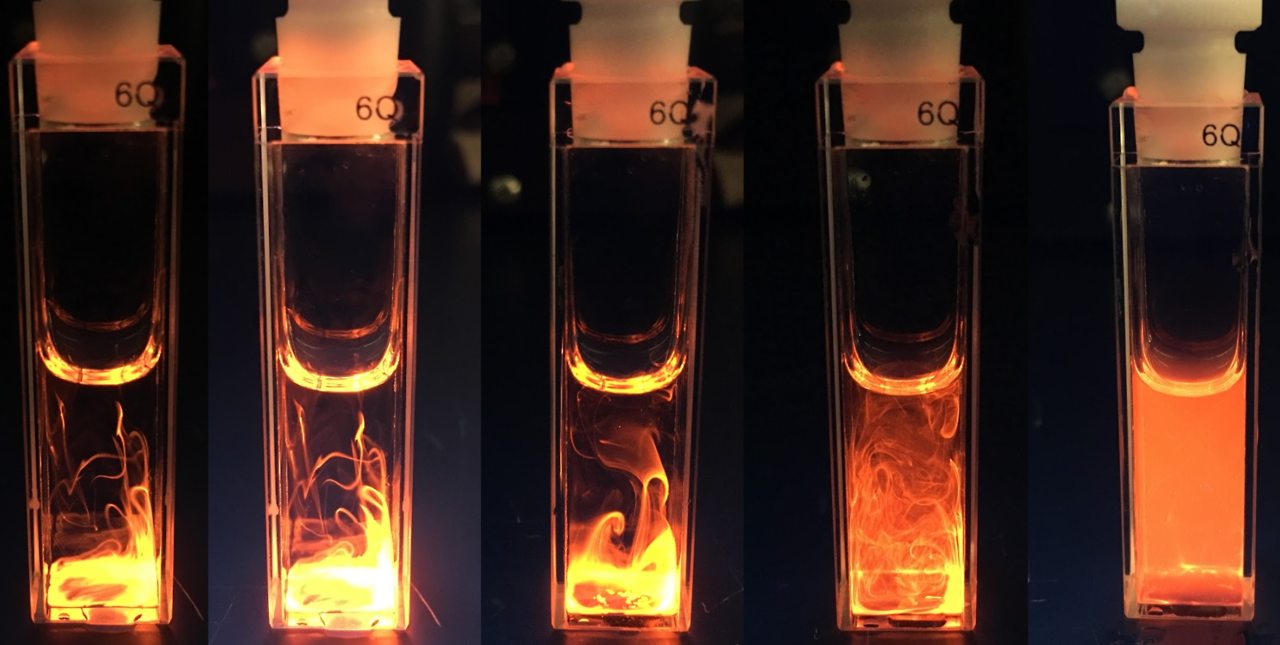

Continuous caramel process line

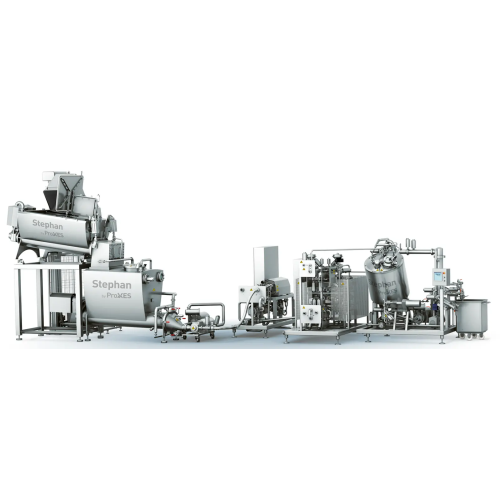

Optimize your continuous food processing with an engineered-to-order line tailored for precise heating, cooking, and cooling cycles, enhancing product quality and efficiency.

Processes and Blends Ingredients Continuously

The Conti Preparation Lines by ProXES offer an innovative solution for continuous, high-speed production across multiple industries, including food, personal care, pharmaceutical, and advanced materials. These lines feature a modular design that seamlessly integrates into existing operations, enabling the precise processing of liquids, powders, and slurries. With their robust blending and emulsifying capabilities, these systems efficiently produce a diverse range of end products such as caramel candy, cheese dips, and aloe vera lotions. Equipped with advanced automation and PLC control, the lines ensure optimal process management and scalability, accommodating throughputs of up to 4,000 kg per hour. Known for their energy efficiency, they reduce operational costs by leveraging highly efficient motor control systems. Constructed from high-grade materials like stainless steel, they offer excellent corrosion resistance, making them suitable for handling various chemical formulations. Adhering to GMP standards, these lines support stringent quality requirements and include a fully integrated CIP system for effective, rapid cleaning. ProXES provides comprehensive engineering support and customization options to tailor these lines to your specific production needs.

Benefits

- Enhances production efficiency by seamlessly integrating with continuous processing lines.

- Optimizes energy usage with advanced motor controls, reducing operational costs.

- Ensures high product quality with precise mixing and emulsifying capabilities.

- Facilitates rapid cleaning and maintenance with an integrated CIP system.

- Provides versatile processing solutions suitable for diverse industry applications.

- Applications

- Sauces, Gels, Bakery, Table sauces, Processed cheese, Pesticides, Ointment, Vegan, Chocolate, Hummus, Soups, Soft gels, Mascara, Toothpaste, Chemical suspensions, Cream cheese, Sweet spreads, Lotions, Nail polish, Shower gel, Ceramics, Pet food, Grease, Fertilisers, Drinks, Mustard, Baby food, Paints, Lacquers, Fillings, Creams, Ketchup, Make-up cream, Stews, Savoury spreads, Mayonnaise, Dressings, Eye drops, Shampoo, Lubricants, Lipstick

- End products

- Beef stew, Vegan cheese, Worcestershire sauce, Chocolate filling, Vitamin soft gels, Hydrocortisone ointment, Automotive grease, Crop-safe pesticides, Almond butter, Nitrogen fertilisers, Dijon mustard, Garlic hummus, Olive oil mayonnaise, Almond milk, Epoxy paint, Hand cream, Croissants, Matte lipstick, Herbal shampoo, Caramel candy, Cheese dip, Strawberry jam, Porcelain tiles, Nanoparticle suspensions, Vinaigrette dressing, Marinara sauce, Cat kibble, Aloe vera lotion, Milk chocolate bars, Top coat nail polish, Artificial tears, Waterproof mascara, Gloss varnish, Hair gel, Charcoal toothpaste, Aloe vera shower gel, Silicone lubricants, Chicken soup, Cream cheese frosting, Foundation cream, Tomato ketchup

- Steps before

- Fat melting, Starch dissolving, Feeding, Soaking, Pre-cutting

- Steps after

- Vacuum cooling, Cooling, Deaeration, Sieving, Final cutting

- Input ingredients

- fat, starch, ingredient, cheese, chili, hummus, mustard seeds, nut paste ingredients, puree ingredients, tahini ingredients

- Output ingredients

- caramel filling, block cheese, spreadable cheese, chili sauce, hummus, classic mustard, dijon mustard, ready-to-use therapeutic food, vegetable purees, tahina

- Market info

- Proxes is known for manufacturing advanced processing systems for the food, pharmaceutical, and chemical industries, offering expertise in mixing, homogenizing, and size reduction technologies with a strong reputation for engineering tailored equipment solutions.

- Capacity

- 1, 500–4, 000 kg/h

- Heating Temperature

- Up to 145°C

- Cooling Temperature

- Down to 80–85°C

- Vacuum Cooking

- Yes

- Automation

- Continuous

- Process Configuration

- Customized

- Cooling Method

- Indirect

- Pressurized Cooking

- Yes

- Deaeration

- Vacuum Deaeration

- Cooking Method

- DSI (Direct Steam Injection)

- Cutting Functions

- Pre-cutting and Final Cutting

- Working mechanism

- Continuous / Batch

- CIP/SIP

- CIP 121°C / SIP 135°C

- Automation level

- Manual / PLC / SCADA

- Integrated steps

- Fat melting, Mixing, Cooking

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Cleaning method

- CIP / Manual

- Batch vs. continuous operation

- Batch / Inline Continuous

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Tank shape

- Round / Rectangular

- Tank size

- Variable based on configuration

- Feed method

- Automatic / Manual

- Discharge method

- Gravity / Pneumatic

- Control panel type

- HMI/PLC interface

- Integration possibilities

- Modular kit system compatible