Heat exchangers for efficient heat transfer in industry

Achieve precise temperature control across diverse viscosities with this innovative scraped surface heat exchanger, perfect for maintaining product integrity during continuous processing of sensitive liquids and slurries.

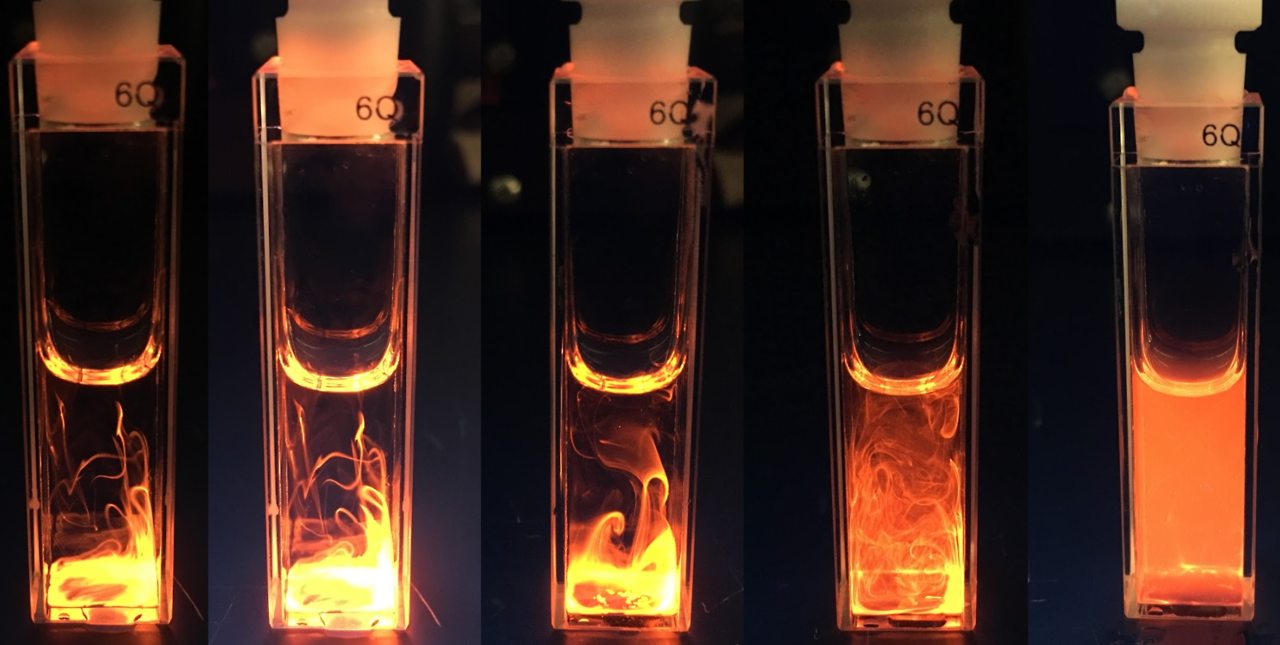

Processes Viscous Products with Gentle Heat Transfer

The Terlotherm Scraped Surface Heat Exchanger from ProXES is designed to handle the complex needs of industries ranging from food processing to pharmaceuticals. It stands out with its continuous operation capability and gentle heat transfer, crucial for maintaining the integrity of sensitive or viscous products. This heat exchanger excels in processes like pasteurization, crystallization, and emulsifying, accommodating a variety of end-products including soups, creams, and chemical suspensions.

With a processing capacity of up to 10,000 kg/hour, it supports large-scale production while ensuring efficiency. The system is integrated with PLC controls for seamless automation and remote monitoring, making it an effortless addition to your existing operation. Energy efficiency is prioritized through optimized motor control, reducing energy consumption significantly.

Constructed from high-grade materials such as stainless steel, it provides excellent durability and corrosion resistance, suitable for diverse industrial applications. The Terlotherm meets stringent hygiene standards, equipped with a CIP system for effective cleaning and minimal downtime, ensuring compliance with industry regulations.

Customization options are available to meet specific operational requirements, backed by ProXES’ robust engineering support to tailor your heat exchanger configuration for optimal performance.

Benefits

- Enhances product quality by preserving delicate consistencies through gentle heat transfer.

- Increases productivity with continuous operation and high processing capacity.

- Reduces operational costs through energy-efficient motor optimization.

- Ensures easy compliance with hygiene standards via integrated CIP system.

- Offers flexibility with customizable configurations to match specific production needs.

- Applications

- Sauces, Gels, Potato mash, Table sauces, Processed cheese, Pastry, Pesticides, Ointment, Chocolate, Bakery products, Dairy, Hummus, Soups, Soft gels, Mascara, Toothpaste, Chemical suspensions, Cream cheese, Sweet spreads, Lotions, Nail polish, Shower gel, Ceramics, Fruit, Pet food, Grease, Vegan products, Fertilisers, Drinks, Mustard, Baby food, Paints, Lacquers, Fillings, Creams, Ketchup, Make-up cream, Stews, Confectionary, Savoury spreads, Mayonnaise, Dressings, Eye drops, Shampoo, Lubricants, Vegetables, Lipstick

- End products

- Omega-3 soft gels, Béchamel sauce, Beef stew, Vegan cheese, Dog kibble, Apple puree, Infant formula, Organic fertilizer, Chocolate ganache, Fruit juice, High-performance grease, Fluoride toothpaste, Nut butter spreads, Dark chocolate bars, Soy sauce, Moisturizing shower gel, Hand cream, Croissants, Olive oil dressing, Carrot mash, Hair styling gel, Cheddar cheese, Cheesecake filling, Herbal shampoo, Antifungal ointment, Milk-based yogurt, Tomato soup, Lip gloss, Strawberry jam, Creamy potato puree, Acrylic paint, Porcelain tiles, Glossy lacquer, Traditional hummus, Aloe vera lotion, Artificial tears, Waterproof mascara, Silicone suspension, Honey mustard sauce, Herbal pesticide, Hydraulic oil, Gel nail polish, Liquid foundation, Tomato ketchup

- Steps before

- Emulsification, Grinding, Homogenizing, Deaerating

- Steps after

- Sterilization, Packing, Cooling, Crystallizing

- Input ingredients

- soups, sauces, dairy, fruit, vegetables, confectionary, pastry, potato mash, creams, lotions

- Output ingredients

- pastuerized soups, cooled sauces, heated dairy products, crystallized fruit, cooked vegetables, confectionary, pastry, processed potato mash, gently mixed creams, lotions

- Market info

- Proxes is known for manufacturing advanced processing systems for the food, pharmaceutical, and chemical industries, offering expertise in mixing, homogenizing, and size reduction technologies with a strong reputation for engineering tailored equipment solutions.

- Capacity

- Up to 10, 000 kg/h

- Functionality

- Pasteurization, Cooling, Heating, Crystallization, Cooking

- Application Areas

- Soups, Sauces, Dairy, Fruit, Vegetables, Confectionery, Pastry, Potato Mash, Creams, Lotions

- Type

- Scraped Surface Heat Exchanger

- Operation

- Continuous

- Working mechanism

- Scraped surface heat exchange

- Flow operation

- Continuous

- Integrated steps

- Pasteurization, cooling, heating, crystallization, cooking

- Capacity

- Up to 10, 000 kg/h

- Density/Particle Size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Control panel type

- PLC / HMI

- Capacity customization

- Up to 10, 000 kg/h

- Integration possibilities

- SCADA compatible

- Footprint customization

- Compact design options