Viscous and liquid product processor

Optimize your production of viscous slurries and liquid formulations with a versatile processor designed for continuous high-speed operations, ensuring precise emulsification and microcutting to enhance product consistency and quality.

Processes Liquid and Viscous Slurry Products

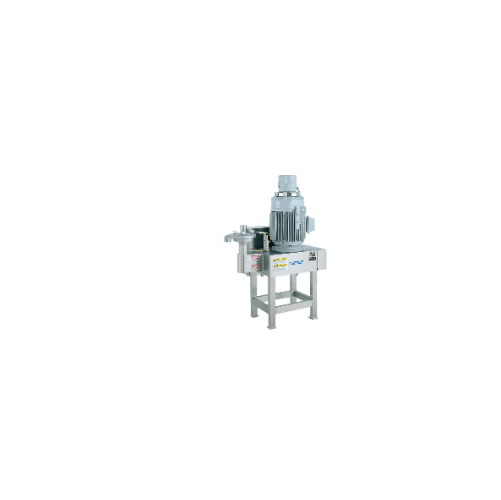

The Comitrol Processor Model 1500 from Urschel Laboratories is engineered to efficiently handle the reduction and emulsification of liquid and viscous slurry products. This machine utilizes a 6-inch diameter Microcut Head, enabling operators to achieve a range of particle sizes from coarse to fine emulsions. It offers continuous operation, ensuring uninterrupted production suited for food, beverage, and pharmaceutical industries. With a processing capacity powered by 15, 30, or 40 HP motors, it seamlessly integrates into high-speed, continuous processing environments. Its applications include the production of fruit juice concentrates, sauces, purees, and topical formulations, making it indispensable for processors of soy milk, almond paste, chili sauces, and more. Designed with simplicity in cleaning and maintenance, it supports hygienic compliance, critical for maintaining quality in sensitive production lines. Available material options enhance chemical compatibility, and Urschel offers test cut services to guarantee optimal configuration for your specific applications.

Benefits

- Enhances production efficiency with continuous operation, minimizing downtime.

- Optimizes energy use with motor options tailored to specific processing needs.

- Facilitates easy cleaning and maintenance, reducing labor and operational costs.

- Ensures precise particle size control for consistent product quality and formulation.

- Versatile application range across food, beverage, and pharmaceutical industries.

- Applications

- Chili paste, Ketchup, Sauces, Liquid formulations, Viscous slurries, Fruit nectars, Soy milk, Food processing, Ointments, Gelatin capsule ingredients, Almond paste, Pharmaceutical ingredients, Vegetable purees, Beverage concentrates, Creams

- End products

- Fruit juice concentrates, Skin ointments, Topical creams, Liquid dietary supplements, Barbecue sauce, Soy-based drinks, Hot chili sauces, Gel capsule fill material, Pharmaceutical suspensions, Vegetable smoothie bases, Mango puree, Viscous soup bases, Almond butter, Tomato ketchup

- Steps before

- Purification, Drying, Emulsification, Grinding

- Steps after

- Sterilization, Packing, Coating, Tablet Pressing

- Input ingredients

- fruit nectars, soy beans, ketchup, barbecue sauce, vegetable purees, beverage concentrates, creams, ointments, gelatin capsule ingredient, almond paste, buffalo sauce, soy milk, seaweed, chili paste, collagen, mango puree, benzoyl peroxide, tomato catsup

- Output ingredients

- free-flowing liquids, viscous slurries, coarse to fine emulsions

- Market info

- Urschel is known for its expertise in precision cutting technology and manufacturing industrial food processing equipment, especially cutting machines. It has a strong reputation for quality and innovation in delivering engineered-to-order solutions for the food processing industry.

- Motor Power

- 15, 30, or 40 HP (11.2, 22.4, or 30 kW)

- Maximum Input Size

- 3/8" (9.5 mm)

- Cutting Head Diameter

- 6" (152.4 mm) diameter Microcut Head

- Machine Length

- 51.9" (1318 mm)

- Machine Width

- 33.03" (839 mm)

- Machine Height

- 72.17" (1833 mm)

- Machine Net Weight

- 1100 lb (499 kg)

- Continuous Operation

- Yes

- Automation Level

- Manual / Continuous

- Cleaning Method

- Easy Cleanup

- Batch vs. Continuous Operation

- Continuous

- Particle Size Control

- Coarse to Fine Emulsions

- Viscous and Liquid Processing Capability

- Yes

- Integration with Microcut Heads

- 6'' Diameter

- Motor Power Variability

- 15, 30, or 40 HP

- Input Size Limitation

- Maximum 3/8" (9.5 mm)

- Abrasion resistance

- High

- Biological compatibility

- Food grade materials

- Cleanability

- Easy to clean design

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Density/particle size

- Up to 3/8" (9.5 mm)

- Viscosity

- Free-flowing to viscous slurries

- Max Input Size

- 3/8" (9.5 mm)

- Product Types

- Liquid, Viscous Slurries

- Cut Type

- Coarse to fine emulsions

- Operating Mode

- Continuous

- Machine Footprint

- Length

- Net Weight

- 1100 lb (499 kg)

- Motor Power

- 15, 30, or 40 HP (11.2, 22.4, or 30 kW)

- Input Size

- Maximum 3/8" (9.5 mm) in any dimension

- Cutter Type

- Microcut Head

- Dimension of Cutting Head

- 6" (152.4 mm) diameter

- Motor Power Options

- 15, 30, or 40 HP (11.2, 22.4, or 30 kW)

- Reduction Head Type

- Microcut 6" (152.4 mm) diameter style

- Impeller Selection

- Varies with application