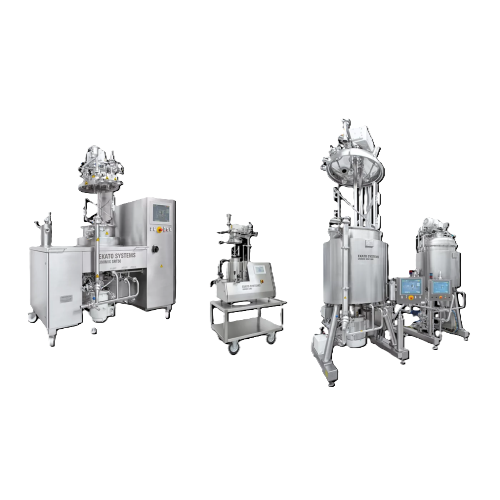

Vacuum processing units for high-viscosity products

For manufacturers seeking to streamline production of high-viscosity emulsions and gels, these vacuum processing units ensure optimal mixing and homogenization, significantly reducing processing times while maintaining product quality.

Mixes, Homogenizes, and Circulates High-Viscosity Products

The UNIMIX Vacuum Processing Units by EKATO SYSTEMS redefine precision mixing and homogenization across industries like cosmetics, pharmaceuticals, and chemicals. Featuring the patented EKATO PARAVISC impeller and S-JET homogenizer, these units excel in processing products with varying viscosities, from lotions and creams to gels and serums. Designed for both batch and continuous operations, they incorporate advanced automation with a PLC-controlled interface and remote monitoring capabilities. Available capacities range from 100 to 20,000 liters, accommodating both laboratory and large-scale production environments. The units boast energy-efficient heating and cooling functions, optimizing resource use. Built to withstand demanding conditions, they are available in corrosion-resistant materials, ensuring longevity and reliability in diverse applications. These systems comply with GMP standards and include an integrated CIP system for effective and contamination-free cleaning, while offering extensive customization options to meet specific production needs.

Benefits

- Ensures consistent product quality across varying viscosities, enhancing end-product reliability.

- Saves time and labor costs with automated processes, including precise mixing and homogenization.

- Optimizes resource use through efficient heating and cooling functions, lowering operational expenses.

- Facilitates quick and thorough cleaning with integrated CIP systems, reducing production downtime.

- Tailors to specific production needs with customizable configurations, improving manufacturing versatility.

- Applications

- Chemicals, Food, Gels, Suspensions, Toothpaste, Cosmetics, Ointments, Skin care products, Creams, Pharmaceuticals

- End products

- Moisturizing creams, Anti-aging serums, Sunscreen lotions, Mascara, Liquid detergents, Skin exfoliants, Liquid cough syrups, Vitamin supplements, Hair gels, Foundation makeup, Flavor emulsions, Anti-dandruff shampoos, Lotions, Antiseptic creams, Toothpaste with fluoride

- Steps before

- Emulsification, Grinding

- Steps after

- Sterilization, Packing

- Input ingredients

- raw materials, liquids, solids, powder, emulsions, gels

- Output ingredients

- lotions, creams, gels, toothpastes, mascaras, ointments, suspensions, skin care products, cosmetics, food products, chemical products

- Market info

- Ekato is renowned for its expertise in mixing technology and process engineering, providing innovative and high-quality solutions for industrial mixing processes across various sectors, including chemical, pharmaceutical, and cosmetics industries.

- Capacity

- 100 L to 20, 000 L

- Automation

- Automated product feed

- Homogenization method

- Internal/external via S-JET

- Vacuum capability

- ASME, PED or SELO compliant tanks

- Heating and cooling function

- Included

- Cleaning method

- Cleaning in place (CIP)

- Homogenization shear speed

- High-shear, variable

- Mixing type

- Vertical and radial mixing

- Discharge method

- An additional pump is not necessary

- Discharged via S-JET

- Seal system

- Double-acting mechanical seal

- Liquid and solids suction

- Direct to high-shear zone

- Design standard

- cGMP compliant

- Variable shear energy input

- Yes

- Working Mechanism

- Homogenizer and agitator combination

- Batch vs. Continuous Operation

- Batch

- Automated Process Control

- Integrated automation system

- Cleaning Method

- Cleaning in Place (CIP)

- Homogenization Mode

- Internal and external homogenization

- Dispersion

- Immediate dispersion of raw materials

- Product Recirculation

- Short-circuit-free internal/external

- Temperature Control

- Heating and cooling function

- Shear Energy Input

- Variable shear energy

- Process Versatility

- Suitable for varying viscosities

- Powder Suction

- Direct suction into homogenizer

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Tank size

- 100 L to 20, 000 L

- Machine footprint

- Depends on model, size

- Control panel type

- Automated with full process control

- Discharge method

- EKATO S-JET for product discharge

- Heating and cooling function

- Integrated

- Lifting Column

- Available for certain models

- Control panel type

- Touchscreen HMI / PLC

- Integration possibilities

- SCADA/PLC/DCS integration

- Mixing,homogenization

- Internal/External

- Automation level

- Manual / Semi-automatic / Fully automatic

- Vacuum control system

- Automated vacuum system

- Capacity range

- 100 L to 20, 000 L

- Heating and cooling

- Integrated / Adjustable

- Cleaning system

- CIP compatible