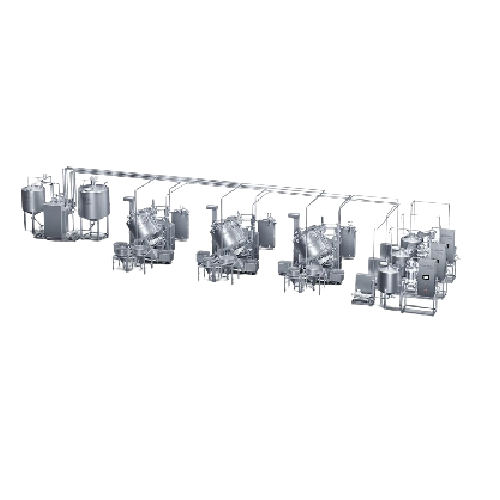

Continuous mustard production line

Optimize your condiment production with precision-engineered systems capable of transforming raw mustard seeds into high-quality, diverse mustard varieties, ensuring consistency and efficiency in your production line.

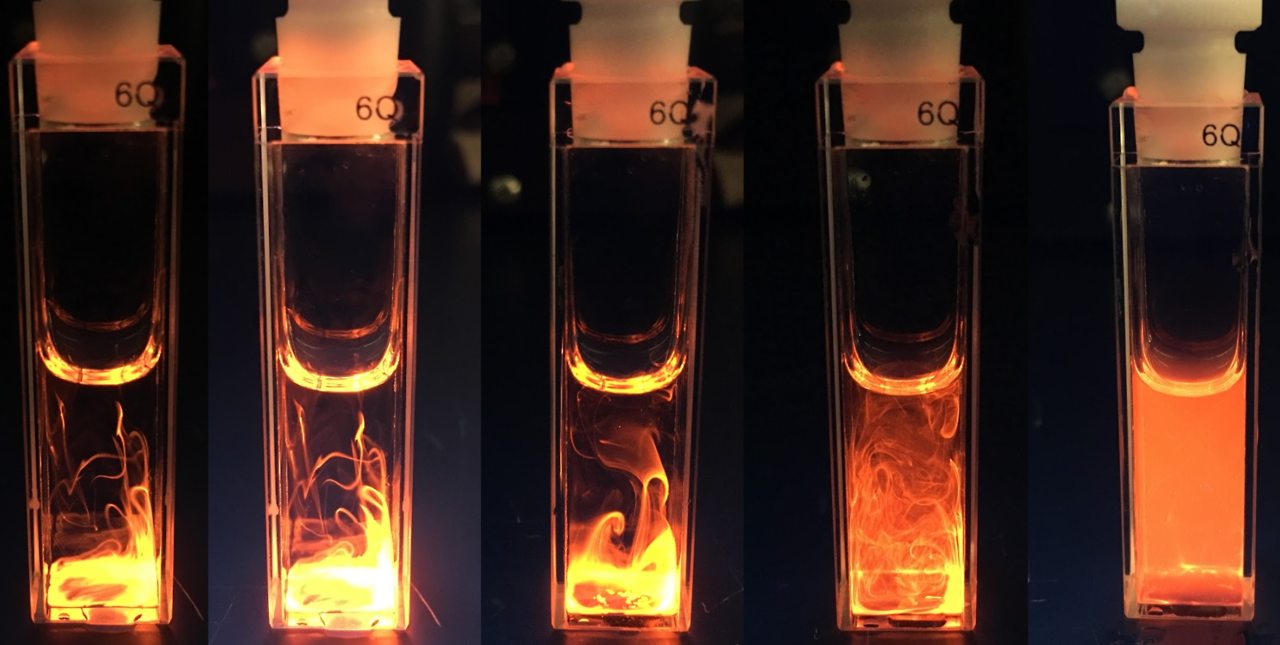

Processes and Mixes Solids, Liquids, and Slurries

The Continuous Vacuum Cooking and Mixing System from ProXES excels in precise thermal processing for a range of applications. Ideal for food and pharma industries, it ensures consistent production of high-quality end products like caramel candy fillings, hummus, and pharmaceutical ointments. This system utilizes advanced vacuum cooking for energy-efficient heating and mixing, providing controlled environments to enhance texture and flavor. Capable of processing up to several thousand kilograms per hour, it offers seamless integration with existing lines through PLC-controlled automation and remote monitoring. Made from corrosion-resistant materials, it complies with industry standards for food safety and pharmaceutical manufacturing. The system supports clean-in-place (CIP) processes for efficient and hygienic maintenance, with customizable features to meet specific production needs.

Benefits

- Enhances product consistency and quality through precise thermal processing.

- Optimizes energy use, reducing operational costs with efficient vacuum technology.

- Increases production capacity with continuous high-speed operations.

- Ensures compliance with industry standards for safety and hygiene.

- Minimizes maintenance time with integrated clean-in-place (CIP) features.

- Applications

- Sauces, Gels, Pesticide, Bakery, Table sauces, Ointment, Vegan, Chocolate, Hummus, Soups, Soft gels, Mascara, Toothpaste, Chemical suspensions, Fertiliser, Cream cheese, Sweet spreads, Lotions, Nail polish, Shower gel, Ceramics, Pet food, Grease, Drinks, Mustard, Baby food, Paints, Lacquers, Fillings, Creams, Ketchup, Make-up cream, Stews, Savoury spreads, Mayonnaise, Dressings, Eye drops, Shampoo, Processed, Lubricants, Lipstick

- End products

- Omega-3 soft gels, Dog kibble, Strawberry fruit jam, Mozzarella cheese, Organic pesticide spray, Antibacterial ointment, Dijon mustard, Lemon-scented shower gel, Fluoride toothpaste, Lobster bisque, Almond butter spread, Water-based chemical coating, Organic salad dressings, Herb-infused savoury spreads, Aloe vera gel, Flavored energy drinks, Scented shampoo, Hydrating lip balm, Roasted red pepper hummus, Synthetic motor oil, Assorted chocolate truffles, Pesto sauce, Caramel candy filling, Exterior house paint, Porcelain tea cups, Artificial tears, Waterproof mascara, Muesli base flakes, Vibrant nail polish, Vegan cheese spread, Anti-aging face cream, Spicy bbq sauce, Foundation cream

- Steps before

- Fat melting, Starch dissolving, Ingredient dosing, Feeding, Soaking, Pre-cutting, Grinding

- Steps after

- Vacuum cooling, Flash-cooling, Sieving, Buffering, Cooling, Packing

- Input ingredients

- Fat, Starch, Ingredients, Cheese, Chili, Hummus, Mustard, Nut paste, Vegetables, Sesame seeds

- Output ingredients

- Caramel filling, Processed cheese, Chili sauce, Hummus, Classic mustard, Dijon mustard, Ready-to-use therapeutic food, Vegetable purees, Tahina

- Market info

- Proxes is known for manufacturing advanced processing systems for the food, pharmaceutical, and chemical industries, offering expertise in mixing, homogenizing, and size reduction technologies with a strong reputation for engineering tailored equipment solutions.

- Capacity

- Up to 4, 000 kg/h

- Heating Temperature

- Up to 145°C

- Flash-Cooling Temperature

- Down to 80…85°C

- Automation

- Continuous preparation

- Vacuum Cooking

- Yes

- Cooling Method

- Indirect

- Evaporation

- Under Vacuum

- Cheese Blending Type

- Cold Blend

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Control panel type

- PLC / HMI

- Integration possibilities

- Modular

- Recipe management

- Customizable

- Machine configuration

- Adjustable for different capacities

- Process adaptation

- Customizable for specific applications

- Modular kit system

- Available

- Brand compatibility

- FrymaKoruma, Stephan, Terlet

- Application range

- Baby food, bakery, chocolate, etc.