Cleaning systems for food, pharmaceuticals, and cosmetics

Ensure optimal hygiene and safety with advanced cleaning systems designed for thorough, efficient removal of both visible and invisible contaminants in your production process.

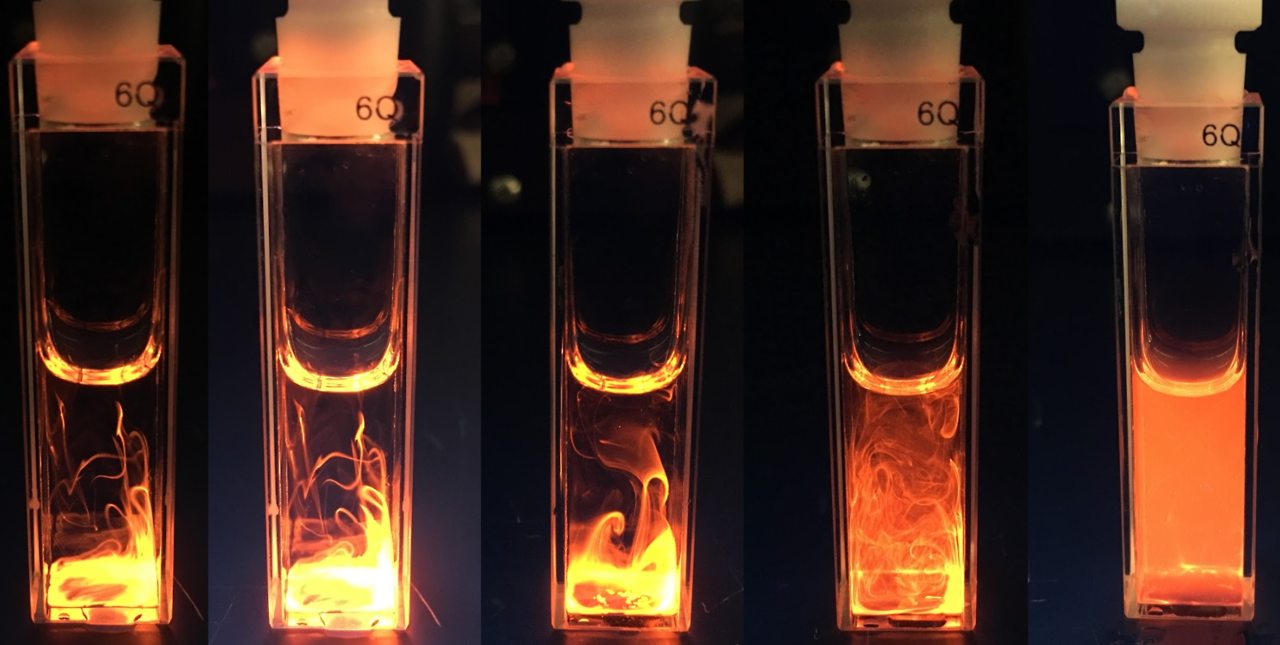

Performs Comprehensive Cleaning and Sanitization

The ProCIP System by ProXES offers state-of-the-art CIP solutions designed to tackle the rigorous hygiene demands of food processors, pharmaceutical manufacturers, and cosmetic producers. Utilizing a combination of time, action, chemistry, and temperature (TACT), these systems ensure efficient removal of contaminants across tanks, pipes, and combined objects, crucial for industries requiring aseptic operations. Supporting capacities up to 20,000 liters with throughput reaching 50 m³/h, ProCIP systems are versatile, integrating seamlessly into both batch and continuous operation settings. Options for single-use and recovery configurations enhance sustainability while the robust PLC controls facilitate automation and integration into existing lines. Constructed from high-grade stainless steel, these systems resist corrosion and guarantee compliance with strict industry standards, including GMP. Their design emphasizes minimal downtime, featuring easy integration with existing processes and offering comprehensive engineering support for tailored hygienic solutions.

Benefits

- Ensures hygienic production by effectively eliminating both visible and invisible contaminants.

- Enhances sustainability through recovery and re-use options, minimizing waste.

- Reduces operational downtime with efficient CIP processes for quick turnaround.

- Complies with industry standards, ensuring safe integration into food, pharma, and cosmetic lines.

- Offers scalability with high-capacity throughput suitable for large-scale industrial applications.

- Applications

- Sauces, Gels, Bakery, Table sauces, Processed cheese, Pesticides, Ointment, Vegan, Chocolate, Hummus, Soups, Soft gels, Mascara, Toothpaste, Chemical suspensions, Cream cheese, Sweet spreads, Lotions, Nail polish, Shower gel, Ceramics, Pet food, Grease, Drinks, Mustard, Baby food, Paints, Lacquers, Fillings, Creams, Fertilizers, Ketchup, Make-up cream, Stews, Savoury spreads, Mayonnaise, Dressings, Eye drops, Shampoo, Lubricants, Lipstick

- End products

- Omega-3 soft gels, Beef stew, Weed killer, Infant formula, Classic hummus, Whipped cream cheese, American cheese slices, Peanut butter, Balsamic vinaigrette, Red lipstick, Body wash, Chocolate ganache, Flavored milk, Antibacterial ointment, Dijon mustard, High-gloss lacquer, Fluoride toothpaste, Olive oil mayonnaise, Anti-aging lotion, Soy sauce, Hydrating shampoo, Aloe vera gel, Stabilized chemical solutions, Bread rolls, Strawberry jam, Acrylic paint, Plant-based burger patties, Porcelain tiles, Liquid fertilizer, Marinara sauce, Moisturizing cream, Industrial lubricants, Waterproof mascara, Chicken noodle soup, Canned dog food, Prescription eye drops, Engine grease, Chocolate bars, Gel nail polish, Foundation cream, Tomato ketchup

- Steps before

- Purification, Emulsification, Deaerating, Particle size reducing

- Steps after

- Sterilization, Packing, Pasteurizing, Product start-up

- Input ingredients

- food processing ingredients, pharmaceutical ingredients, cosmetic ingredients, baby food, bakery ingredients, chocolate, drinks, hummus, savory spreads, ketchup, table sauces, mayonnaise, dressings, mustard, processed, cream cheese, stews, soups, sauces, sweet spreads, fillings, vegan ingredients, pet food, api suspensions, creams, lotions, eye drops, gels, lipstick, mascara, make-up cream, nail polish, ointment, shampoo, shower gel, soft gels, toothpaste, ceramics, chemical suspensions, grease, lubricants, paints, lacquers, pesticide, fertiliser

- Output ingredients

- cleaned tanks, cleaned pipes, cleaned combined objects, recorded cleaning data

- Market info

- Proxes is known for manufacturing advanced processing systems for the food, pharmaceutical, and chemical industries, offering expertise in mixing, homogenizing, and size reduction technologies with a strong reputation for engineering tailored equipment solutions.

- Tank Capacity

- up to 20, 000 L

- Throughput

- up to 50 m³/h

- Cleaning Method

- Single-use and recovery systems

- Cleanability

- Internal and External

- Automation

- Monitoring and Reporting

- Main Applications

- Tank and Pipe Cleaning

- Functions

- Preparation and Storage of Cleaning Solutions

- Working Mechanism

- Batch and Continuous Operation

- Integrated Steps

- Cleaning Solution Preparation, Storage, Distribution

- CIP Principles

- TACT (Time, Action, Chemistry, Temperature)

- Automation Level

- PLC-based Monitoring and Reporting

- Batch vs Inline Flow

- Single-use and Recovery Systems

- Internal and External Options

- Cleaning Method

- CIP (Clean-in-Place)

- Tank Capacity

- Up to 20, 000 L

- Throughput

- Up to 50 m³/h

- Main Applications

- Tank, Pipe, Combined Cleaning

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container size and shape

- Variable

- Footprint

- Compact / Customizable

- Tank capacity

- Up to 20, 000 L

- Throughput

- Up to 50 m³/h

- Tank shape

- Cylindrical

- Control panel type

- Touchscreen / PLC

- Discharge method

- Piping / Integrated Systems

- Control panel type

- Touchscreen / Button interface

- Integration possibilities

- SCADA / MES integration

- Tank capacity options

- Up to 20, 000 L

- Throughput options

- Up to 50 m³/h

- Cleaning solution preparation

- Single-use / Recovery systems

- System type

- Internal / External