Automated weighing system for tablets

Ensure precision in pharmaceutical manufacturing by seamlessly integrating advanced weight testing directly with your tablet press, enabling real-time self-adjustment and preventing potential issues caused by weight drift.

Automates Continuously Weighing for Tablet and Capsule Production

The WT50 from SOTAX is a comprehensive, online weight tester designed for precision in pharmaceutical manufacturing. This system seamlessly integrates with various tablet press brands, automating continuous weighing for tablets and capsules. Featuring a high-precision weighing module, the WT50 operates with a vibration-resistant mechanism ideal for the demanding conditions of compression rooms. It handles a wide range of applications, from aspirin tablets to transdermal patches, ensuring consistent product weight for end-products such as gelatin capsules and extended-release pellets.

The WT50’s modular design supports easy integration, allowing for minimal space usage with gravity or venturi feeding options. It automates the determination of minimum weight in compliance with USP <41>, providing detailed reports for quality assurance. Sample collection capabilities are included for further lab testing, without increasing the system’s footprint. The WT50’s programmable cleaning intervals and elevated weighing platform reduce downtime and contamination risk, optimizing your production line with less manual intervention.

Benefits

- Enhances product quality by ensuring precise weight control and reducing risk of weight drift.

- Saves floor space with compact design, ideal for high-density manufacturing areas.

- Minimizes manual intervention and labor with fully automated, continuous operation.

- Complies with USP standards, ensuring regulatory adherence and quality assurance.

- Reduces contamination risk with integrated cleaning functions, maintaining reliable operation.

- Applications

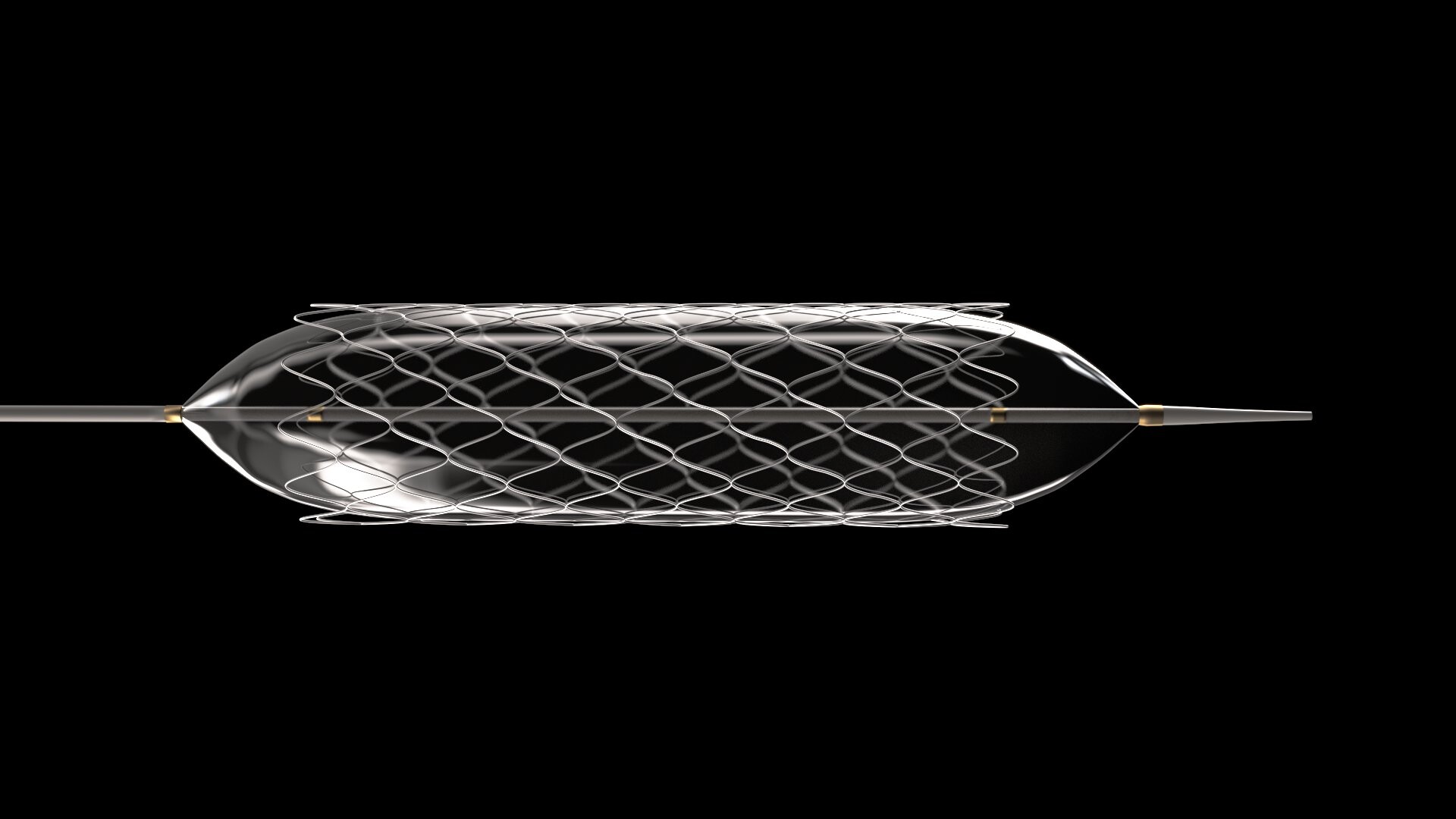

- Medical devices, Gels, Pellets, Granules, Microspheres, Catalysts, Stents, Food, Nano suspensions, Fine chemicals, Soft-gelatin capsules, Implants, Animal health, Capsules, Powders, Washtabs, Transdermal patches, Creams, Suppositories, Semi-solids, Apis, Tablets, Injectable suspensions

- End products

- Ziegler-natta catalysts, Hydrocortisone creams, Liposomal nano suspensions, Industrial fine chemicals, Omega-3 soft-gelatin capsules, Hip implants, Veterinary antibiotic tablets, Vitamin-enriched oat bars, Protein powders, Intravenous vitamin c suspensions, Extended-release pellets, Effervescent granules, Ibuprofen api, Dishwasher washtabs, Rectal suppositories, Nicotine transdermal patches, Iron oxide microspheres, Gelatin capsules, Cardiac stents, Aspirin tablets, Lidocaine gels

- Steps before

- Tablet Compression, Capsule Filling, Mixing, Blending

- Steps after

- Packing, Coating, Lab Testing, Sample Collection

- Input ingredients

- tablets, capsules, pellets, API's, powders, granules, soft-gelatin capsules, suppositories, medical devices, stents, implants, microspheres, nano suspensions, injectable suspensions, semi-solids, gels, creams, transdermal patches, washtabs, fine chemicals, catalysts, food, animal health, coated lenses, bottles with screwcaps

- Output ingredients

- individual sample weights, weight test results, sample collection for lab testing, minimum weight report

- Market info

- Sotax AG is renowned for its expertise in manufacturing high-quality pharmaceutical testing equipment, including dissolution testing systems, and has a strong reputation for reliability, precision, and innovation in laboratory and industrial applications.

- Integration

- Automated with different tablet presses

- Footprint

- Compact, small

- Feeding

- Gravity and venturi

- Accuracy

- High-precision

- Cleaning method

- Programmable intervals

- Calibration

- User-guided procedures

- Minimum weight determination

- Automated at installation

- Collection method

- Space-saving sample collector

- Automation level

- Fully Automated

- Batch vs. continuous operation

- Inline Continuous

- Cleaning method

- Programmable Cleaning Intervals

- Integration capability

- Seamless with Tablet Press

- Sample collection

- Space-saving Collector

- Weight Drift Prevention

- Automated Self-Adjustment

- Minimum weight determination

- Automated at Installation

- Vibration resistance

- High-Precision Weighing

- Feeding mechanism

- Gravity / Venturi-Feeding

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- USP Compliance

- USP <41> and USP <1251>

- Machine footprint

- Compact

- Design

- Modular

- Inlet height

- Low

- Discharge method

- Gravity feeding / Venturi-feeding

- Weight

- High-precision weighing module

- Integration

- Seamless with tablet presses

- Vibration resistance

- Yes

- Cleaning mechanism

- Integrated cleaning function

- Sample collection

- Space-saving sample collector

- Control method

- User-guided adjustment

- Integration Possibilities

- Tablet press integration

- Control Panel Type

- User-guided adjustment

- Compact Footprint

- Minimum space requirement

- Modular Design

- Configurable for specific integration

- Feeding Options

- Gravity or venturi feeding

- Sample Collection

- Bulk and double-sided press modes

- Calibration

- User-guided procedures with printed report