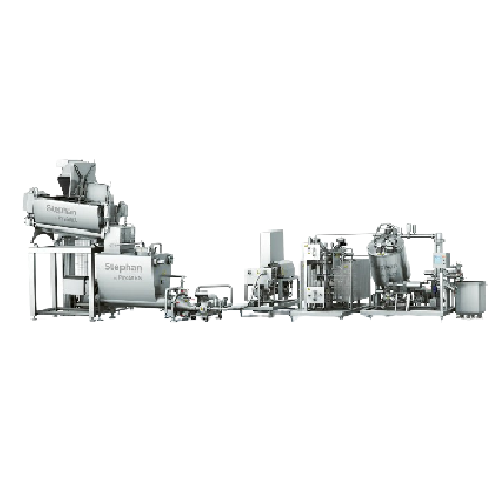

Cheese blending and heating line for processed cheese

Optimize your processed cheese production with a solution that seamlessly blends and heats, ensuring consistent texture and quality from spreadable to block forms, while maintaining peak efficiency in continuous operations.

Processes and Refines Multi-Industry Products

The FrymaKoruma, Stephan, and Terlet Continuous Processing Line offers an integrated solution for manufacturers in food, pharma, and personal care sectors. Utilizing a modular design, it leverages aseptic processing and homogenization to ensure consistent quality across diverse end-products such as caramel fillings, moisturizing creams, and emulsified sauces. Capable of processing up to 4,000 kg/hour, this line supports continuous operations with high-speed throughput. It features PLC control for seamless integration and remote system monitoring, optimizing energy use by up to 25% through advanced motor design. Constructed from durable materials for enhanced corrosion resistance, the equipment meets industry standards, including GMP and FDA, with customizable options for specific production needs. Fast and efficient cleaning is achieved with the integrated CIP system, minimizing downtime and ensuring operational efficiency.

Benefits

- Enhances production efficiency by processing up to 4,000 kg/hour with continuous operation.

- Reduces energy costs by up to 25% with optimized motor systems.

- Ensures product safety and quality, conforming to GMP and FDA standards.

- Minimizes operational interruptions with an integrated CIP system for fast cleaning.

- Offers flexibility and customization to meet specific process and product requirements.

- Applications

- Sauces, Gels, Pesticide, Bakery, Table sauces, Ointment, Vegan, Chocolate, Hummus, Soups, Soft gels, Mascara, Toothpaste, Chemical suspensions, Fertiliser, Cream cheese, Sweet spreads, Lotions, Nail polish, Shower gel, Ceramics, Grease, Drinks, Mustard, Baby food, Paints, Lacquers, Fillings, Creams, Petfood, Ketchup, Make-up cream, Stews, Savoury spreads, Mayonnaise, Dressings, Eye drops, Shampoo, Processed, Lubricants, Lipstick

- End products

- Water-resistant mascara, Cream of mushroom soup, Emulsion paint, Caramel filling for pastries, Brioche, Antibacterial ointment, High-gloss lacquer, Organic pesticide, Fluoride toothpaste, Dry dog food, Cream-filled chocolate, Vegan protein spread, Volumizing shampoo, Long-lasting lipstick, Caesar salad dressing, Glossy nail enamel, Beverage concentrate, Cheese dip, Automotive engine oil, Moisturizing hand cream, Porcelain tiles, Hydrating gel mask, Traditional hummus, Whole grain mustard, Artificial tears, Tinted moisturizer, Aloe-infused shower gel, Vegan butter spread, Nitrogen fertilizer, Fruit jam, Vitamin soft gel capsules, Tomato ketchup

- Steps before

- Ingredient dosing, Fat melting, Starch dissolving, cooking, Cheese blending, Pre-cutting, Feeding

- Steps after

- Cooling, Vacuum cooling, Evaporation (under vacuum), Vacuum deaeration, Sieving, Final cutting if needed

- Input ingredients

- fat, starch, ingredients, cheese, chili, hummus, mustard, nut paste, vegetables, tahina

- Output ingredients

- caramel filling, processed cheese, block cheese, chili sauce, hummus, classic mustard, dijon mustard, ready-to-use therapeutic food, vegetable purees, tahina

- Market info

- Proxes is known for manufacturing advanced processing systems for the food, pharmaceutical, and chemical industries, offering expertise in mixing, homogenizing, and size reduction technologies with a strong reputation for engineering tailored equipment solutions.

- Capacity

- Caramel Line

- Capacity

- Cheese Line

- Capacity

- Chili Line

- Capacity

- Hummus Line

- Capacity

- Mustard Line

- Capacity

- Nut Paste Line

- Capacity

- Puree Line

- Capacity

- Tahina Line

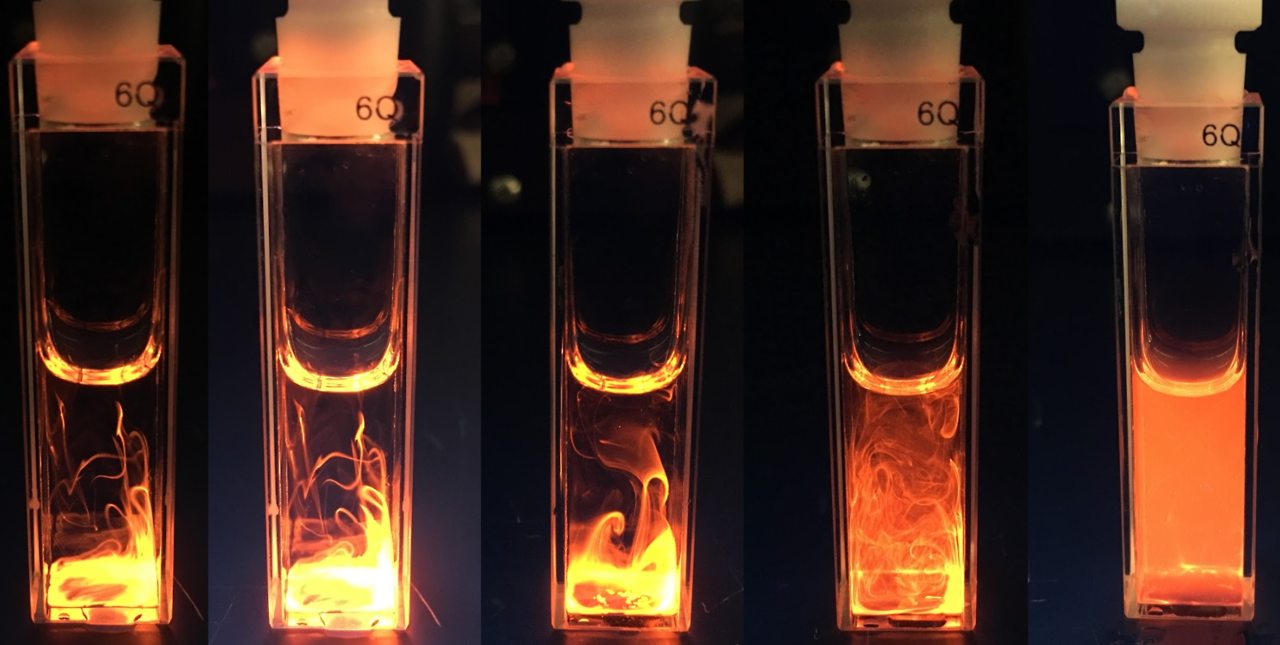

- Cheese Heating Range

- Up to 145°C

- Cheese Cooling Range

- Flash-cooling down to 80…85°C

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Vacuum cooking

- Caramelizing

- Automation level

- Manual / PLC / SCADA

- Integrated steps

- Cutting, Mixing, Cooling

- Working mechanism

- Continuous preparation solutions

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Custom process design

- Modular systems

- Integration possibilities

- Continuous preparation lines

- Recipe and formulation adaptation

- Yes