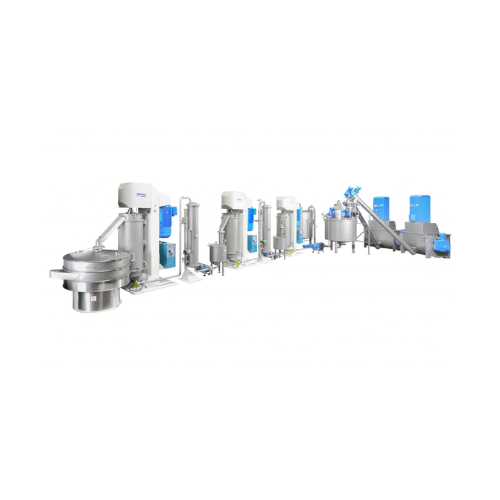

Chocolate processing production line

Efficiently streamline your chocolate and compound production with a fully automatic system capable of continuous weighing, mixing, and fine grinding, ensuring precise control and consistent quality in every batch.

Processes and Grinds Chocolate and Compounds

The CAO 4000[3]-CHOC IN-LINE from Caotech is an engineered-to-order system designed for continuous chocolate and compound processing. This system integrates low-speed agitated ball mills with a Mini Mix unit, enabling precise weighing, mixing, conching, and grinding of chocolates, creams, bread spreads, and fat-based compounds. Capable of producing up to 2,500 kg/h, it operates efficiently with PLC automation, ensuring seamless integration into existing production lines. The system reduces energy consumption and minimizes wear through its optimized motor control and low-speed operation, ensuring quality and reliability. Compact and robust, it requires no foundational support, saving valuable floor space. Ideal for food, chocolate manufacturing, and confectionery industries, it supports diverse applications—from dark chocolate bars and pralines to vegan coatings and nut spreads. Designed with versatility in mind, the CAO 4000[3]-CHOC IN-LINE provides continuous, high-quality product output with minimal maintenance costs, making it indispensable for high-demand production environments.

Benefits

- Enhances production efficiency with continuous processing, increasing throughput up to 2,500 kg/h.

- Reduces operational costs with PLC-controlled automation, minimizing the need for manual intervention.

- Optimizes energy usage, lowering power consumption through advanced motor control.

- Minimizes maintenance costs due to low wear and robust design.

- Saves floor space and installation cost with no requirement for a foundational setup.

- Applications

- Ice cream coatings, Compounds, Fat-based compounds, Chocolate, Bread spreads, Creams

- End products

- Cocoa-based fat compounds, Vanilla cream fillings, Ice cream chocolate chips, Dark chocolate bars, Milk chocolate pralines, Compound chocolate drops, Chocolate hazelnut spread, Vegan chocolate coatings, Buttercream frosting, Nut-based chocolate spreads

- Steps before

- Collect cocoa beans, Grind cocoa beans, Weighing, Mixing

- Steps after

- Conching, Packing, Coating

- Input ingredients

- cocoa beans, crystal sugar, fat, lecithin, vanillin, aroma

- Output ingredients

- chocolate, compound coatings, ice cream coatings, bread spreads, fat-based compounds

- Market info

- Caotech is known for its expertise in designing and manufacturing industrial equipment for processing cocoa, chocolate, and confectionery. The company is reputable for producing high-quality, tailor-made processing machinery, catering to both large-scale operations and niche producers.

- Capacity

- up to 2, 500 kg/h

- Installed Power

- 283 kW

- Weight

- 15, 000 kg

- Dimensions (LxWxH)

- 17000 x 2000 x 3500 mm

- Automation

- PLC-controlled

- Batch vs. continuous

- Inline Continuous

- Working mechanism

- Low-speed agitated ball mills

- Integrated steps

- Weighing, mixing, conching, fine grinding

- Batch vs. continuous operation

- Inline Continuous

- Automation level

- PLC-controlled

- Cleaning method

- Low maintenance

- Energy efficiency

- Low energy consumption

- Density/particle size

- 1.2 mm

- Machine footprint

- 17000 x 2000 x 3500 mm

- Weight

- 15, 000 kg

- Compact footprint

- Limited floor space, no foundation required

- Control panel type

- PLC-controlled

- Discharge method

- Continuous inline

- Compact footprint

- No foundation required

- Control panel type

- Automatic

- Integration possibilities

- Automatic feeding systems

- Discharge method

- Inline continuous