Benchtop dissolution tester for multiple test runs

Streamline your laboratory’s workflow with a fully automated benchtop dissolution system, combining offline sample collection with integrated UV-Vis analysis to enhance productivity and ensure compliance with regulatory standards. Ideal for those seeking to optimize dissolution testing processes with minimal manual intervention.

Conducts Automated Dissolution Testing and UV-Vis Analysis

The AT MD UV On-/Offline from SOTAX is a cutting-edge benchtop dissolution tester offering seamless integration of UV-Vis analysis for comprehensive laboratory applications. This equipment excels in automating dissolution testing processes for pharmaceutical and biotech products, efficiently managing samples from tablets to injectable suspensions. Utilizing a fully automated system, it combines vessel filling, sampling, filtration, and data management into a single process, accommodating both USP basket and paddle methods. The integrated UV-Vis spectrophotometer enables real-time analysis with optional offline sample collection, reducing manual intervention and enhancing productivity. Engineered for regulatory compliance, the AT MD UV offers 21 CFR Part 11 and ALCOA+ data integrity, making it ideal for QC and R&D laboratories. Its compact footprint and robust construction ensure easy placement on standard lab benches, while its modular design supports customized configurations and seamless integration into existing workflows.

Benefits

- Enhances productivity with fully automated, unattended operation, allowing lab personnel to focus on critical tasks.

- Delivers rapid, real-time analysis through seamless UV-Vis integration, reducing cycle times.

- Ensures compliance with 21 CFR Part 11 standards, offering robust data integrity and audit trails.

- Minimizes manual intervention, reducing human error and ensuring consistent test outcomes.

- Offers flexible sample collection, supporting diverse analytical needs and improving workflow efficiency.

- Applications

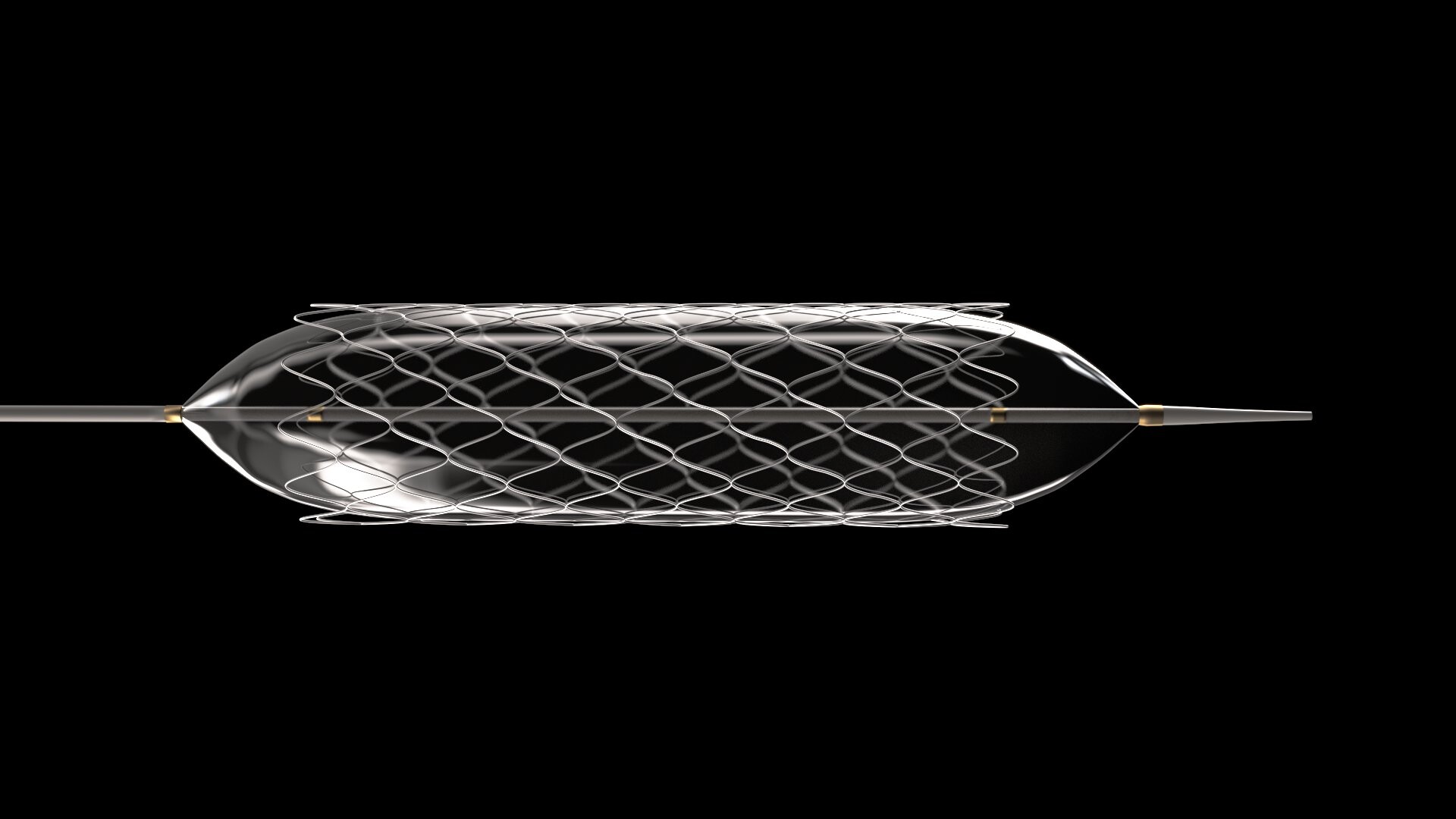

- Medical devices, Gels, Pellets, Microspheres, Catalysts, Stents, Food, Pharmaceutical tablets, Nano suspensions, Fine chemicals, Coated lenses, Soft-gelatin capsules, Implants, Animal health, Capsules, Washtabs, Transdermal patches, Bottles with screwcaps, Creams, Suppositories, Semi-solids, Injectable suspensions

- End products

- Moisturizing creams, Sunscreen gels, Vitamin d capsules, Eye dropper bottles with screwcaps, Knee implants, Veterinary antibiotics, Anti-glare coated lenses, Nicotine patches, Ibuprofen suppositories, Fish oil soft-gel capsules, Zeolites, Coronary stents, Albumin nanoparticles, Dishwasher tablets, Polymerization catalysts, Aspirin tablets, Protein supplements, Dexamethasone injectable suspensions

- Steps before

- Media Preparation, Vessel Filling, Method Development

- Steps after

- Data Reporting, Data Checking, Verification, System Cleaning, Coating, Tablet Pressing

- Input ingredients

- tablets, capsules, pellets, API's, powders, granules, soft-gelatin capsules, suppositories, medical devices, stents, implants, microspheres, nano suspensions, injectable suspensions, semi-solids, gels, creams, transdermal patches, washtabs, fine chemicals, catalysts, food, animal health products, coated lenses, bottles with screwcaps

- Output ingredients

- dissolution test results, UV-Vis analysis data, HPLC analysis data, UPLC analysis data, filtered samples, data governance reports

- Market info

- Sotax AG is renowned for its expertise in manufacturing high-quality pharmaceutical testing equipment, including dissolution testing systems, and has a strong reputation for reliability, precision, and innovation in laboratory and industrial applications.

- Automation

- Fully Automated

- Sample Collection

- Online and Offline

- Dissolution Methods

- USP 1/2/5/6

- Pump Type

- Piston pumps

- Filtration

- 0.2 microns

- UV-Vis Analysis

- Double beam or diode array

- Batch Capacity

- Up to 8 unattended batches

- Compliance

- 21 CFR part 11

- Data Integrity

- ALCOA+ level functionalities

- Control

- User access control

- Footprint

- Compact

- Working mechanism

- Benchtop automation with UV-Vis online and offline sampling

- Integrated steps

- Filling, sampling, cleaning

- Batch vs. continuous operation

- Batch operation

- Automation level

- Fully automated

- CIP/SIP

- CIP compatible post-run cleaning

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Benchtop configuration

- Discharge method

- Automated sample collection

- Control panel type

- User-friendly interface

- Control panel type

- Touchscreen / PLC Interface

- Integration capabilities

- Seamless UV-Vis integration / Data export

- Automation level

- Fully automated / Unattended operation

- Footprint

- Compact benchtop

- Sample collection options

- Tubes / vials / wellplates

- Pump type

- Powerful piston pumps

- Compliance features

- 21 CFR part 11 / ALCOA+ functionalities

- Software integration

- MDsoft for data management

- Monitoring

- CenterView™ video monitoring