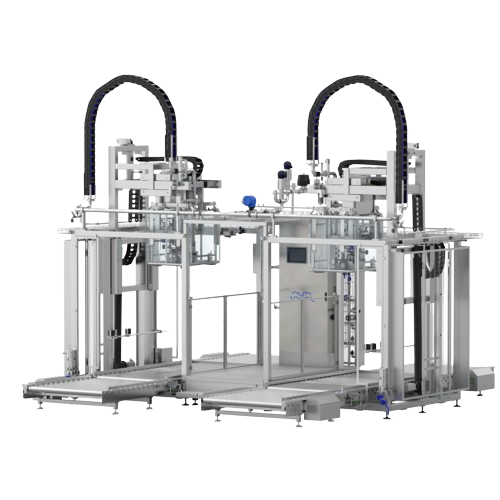

Thousand-litre aseptic filler

Ensure the aseptic filling of bulk liquid and viscous food products, reducing contamination risks and maintaining product integrity from sterilized food ingredients to ready-to-eat meals.

Fills and Seals Sterile Packaging Efficiently

The Thousand-Litre Aseptic Filler (TAF) from Alfa Laval is an engineered-to-order solution designed for food and beverage manufacturers requiring sterile packaging for liquid and viscous products. This versatile inline filling machine efficiently handles prepared foods, beverages, and low-acid products, ensuring each item is safely packaged in aseptic bag-in-box formats. Capable of processing from small 3-litre to large 1,000-litre containers, TAF seamlessly integrates into production lines with automation options for both semi-automatic and high-speed operations. The system’s modular design allows customization, including multiple filling heads and accessories. With a focus on product integrity, the TAF reduces contamination risks and minimizes product losses while maintaining cost-effective operations. Compliance with aseptic validation protocols ensures the highest levels of commercial sterility, making it a reliable choice for industries focused on food safety and quality. Maintenance is simplified through ergonomic design, and Alfa Laval’s global support infrastructure ensures continued productivity and uptime.

Benefits

- Enhances production efficiency with rapid changeovers and adaptable bag sizes.

- Minimizes contamination and product loss, ensuring the integrity of packaged goods.

- Ensures regulatory compliance with adherence to aseptic validation protocols.

- Reduces operational costs with low maintenance requirements and modular design.

- Extends shelf life and ensures sterility, preserving the quality of food and beverages.

- Applications

- Beverages, Viscous food products, Bulk industrial food processing, Liquid foods, Low-acid products, Sterile bag-in-box packaging, Food ingredients, Prepared foods

- End products

- Smoothies, Soups, Sauces, Creams, Cooking bases, Broths, Low-acid beverages, Condiments, Ketchups, Industrial-sized food products, Sterilized food ingredients, Ready-to-eat meals, Juices, Vegetable pastes, Dairy products, Purees

- Steps before

- Sterilization, Heat treatment, Pumping, Transfer from Steritank

- Steps after

- Packing, Distribution, Storage, Shipping

- Input ingredients

- sterile food products, beverages, liquid foods, highly viscous food products, low-acid products with particles

- Output ingredients

- bag-in-box bags, industrial drums, totes, bins, 1000-litre tote-sized bags, containerized bags, 3- to 20-litre bags, 220-litre bag-in-drums, 240- to 400-litre bag-in-carton boxes, 1000-litre bag-in-container

- Market info

- Alfa Laval is renowned for its expertise in heat transfer, separation, and fluid handling technologies, providing innovative, energy-efficient engineered-to-order solutions for various industries including food, marine, and energy.

- Capacity

- 1, 000-litre bags

- Filling speed

- Fast, accurate filling

- Automation

- Automatic / Semi-automatic

- Filling method

- Aseptic

- Changeover time

- Faster changeovers

- Bag type

- Bag-in-box / Industrial totes / Drums

- Filling volume

- 3 to 1, 000 litres

- Automation level

- Automatic / Semi-automatic

- Batch vs. continuous operation

- Inline Continuous

- Changeover time

- Faster changeovers

- CIP/SIP

- Automatic CIP

- Cleaning method

- Easy to clean

- Energy efficiency

- Reduces operating costs

- Biological compatibility

- Aseptic

- Cleanability

- CIP (Cleaning in Place)

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Density/particle size

- Handles highly viscous, low-acid products

- Machine footprint

- Designed for thousand-litre aseptic filling

- Bag capacity

- 3- to 20-litre

- 220-litre bag-in-drums

- 240- to 400-litre bag-in-carton boxes

- 1000-litre bag-in-container

- Filling type

- Aseptic inline filling

- Discharge method

- Inline filling into bags/drums

- Control panel type

- Automatic and semi-automatic options

- Bag size compatibility

- 3–1, 000 litres

- Filling head options

- Multiple heads available

- Operation type

- Automatic / Semi-automatic

- Optional equipment

- Automatic bag feeder (ABF)

- Packaging design flexibility

- Adapts to varying designs

- Product compatibility

- Liquid and viscous products