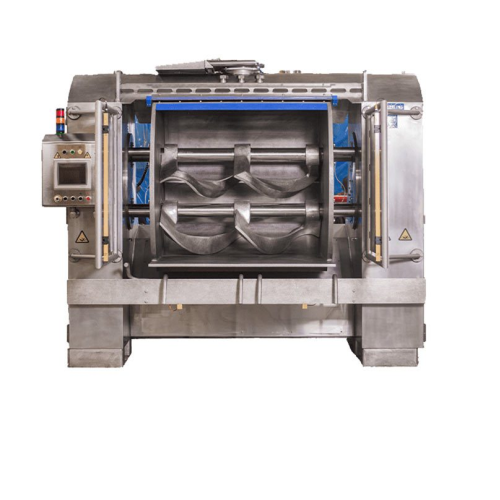

Traditional enclosed frame mixer for dough and batter preparation

Optimize your production with high-capacity mixing, ensuring consistent dough development and efficient processing for varied food products. Achieve superior mixing performance with robust design and advanced features tailored for demanding environments.

Mixes, Kneads, and Shears Dough and Batters

The Traditional Enclosed Frame Mixer from Peerless Food Equipment is engineered for high-capacity production environments. This robust mixer combines durability with efficiency, accommodating a wide range of applications from bread to pastry to pet food. Utilizing a unibody design, it ensures strength and stability during intensive processes like kneading, shearing, and mixing. Certified with ANSI/ASB/Z50.2/BISSC & CE, it is constructed from food-grade 304 stainless steel, ensuring sanitation and corrosion resistance.

Ideal for crafting English muffins, pizza crusts, and cream fillings, this mixer supports batch operations with hydraulic bowl tilts up to 140°, enhancing operational flexibility. The Custom Mixer Cycle System (CMCS) enables precise control over mixing cycles, tailored for specific recipes. Equipped with a high-efficiency, waterproof motor and reinforced drive systems, it minimizes energy consumption while maximizing production uptime.

Integration into existing production lines is seamless, thanks to options such as NEMA-rated control enclosures and advanced automation for remote and centralized monitoring. Maintenance is streamlined with minimal trunnion bearing upkeep and a sanitary drip shield to facilitate easy cleaning. Customization options include a variety of tilt mechanisms, cooling systems, and electrical configurations, supported by Peerless’s engineering team for tailored solutions.

Benefits

- Enhances dough quality and texture across diverse products, improving final product consistency.

- Minimizes operational interruptions with easy-to-maintain components and sanitary design.

- Reduces energy costs with high-efficiency, premium-duty motors and optimized drive systems.

- Increases production flexibility with customizable mix cycles and multiple tilt options.

- Ensures compliance with strict sanitary standards, protecting product safety and integrity.

- Applications

- Roll, Masa, Pasta, Bread, Cake, Tortilla, Pet food, Snack, Biscuit, Pizza, Brownie batter, Cracker, Doughnuts, Bagels, Croissants, Creams

- End products

- Energy bars, Moulded cookies, English muffins, Pizza crust, Italian christmas breads, Fig jam, Pasta dough, Refrigerated pizza, Laminated cookies, Flour tortillas, Granola, Corn tortillas, Sheeted cookies, Cream filling, Wire-cut cookie dough, Taffy, Scones, Pretzels, Muffins

- Steps before

- Dough Preparation, Ingredient Mixing, Material Handling, Bowl Loading

- Steps after

- Dough Shaping, Proofing, Baking, Cooling, Packaging

- Input ingredients

- bread dough, flour tortillas, pizza dough, bagel dough, doughnut dough, croissant dough, bun dough, roll dough, English muffin dough, wire-cut cookie dough, cake batter, energy bar mixture, pretzel dough, granola mix, scone dough, cream filling, Italian Christmas bread mixture, fig jam, cookie dough, cracker dough, biscuit dough, corn tortilla dough, pet food ingredients, cream mixture, brownie batter, pasta dough, taffy

- Output ingredients

- mixed dough, developed dough, kneaded dough, high shear mix, energy transferred dough

- Market info

- Peerless Food Equipment is known for manufacturing high-performance, customized food processing equipment. They specialize in dough handling, mixing, and batch management systems, with a strong reputation for reliability, innovation, and excellent customer service.

- Certifications

- ANSI/ASB/Z50.2/BISSC, CE

- Material

- 304 Stainless Steel

- Motor Efficiency

- IEEE premium duty, waterproof

- Bowl Seal

- FDA-approved material

- Drive System

- Single-end drive with Gates Poly Chain GT Carbon drive belt

- Hydraulic Bowl Tilt

- 120° forward

- Control Enclosure

- NEMA 12/dust-tight, painted remote starter enclosure

- Optional Refrigeration

- Direct expansion jacket fittings

- Agitation Type

- Triple Roller Bar, Double Sigma Arm, Single Sigma Arm, High Shear

- Kneading action

- Consistent kneading for exceptional dough development

- Bowl tilt flexibility

- Hydraulic bowl tilt 120° forward

- Automation level

- Custom Mixer Cycle System (CMCS)

- Bowl seal feature

- FDA-approved material for safety

- Drive system

- Single-end drive for stronger drives, shafts, and bearings

- Cleaning method

- Sanitary drip shield, minimal maintenance trunnion bearings

- Material transfer

- Maximum energy transfer through roller bars

- Frame design

- Heavy-duty “unibody” frame design

- Batch vs. continuous operation

- Batch operation

- Temperature control

- Heavy-duty stainless steel “Z”-type jacket for cooling/warming

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Unibody frame design

- Heavy-duty

- Bowl capacity

- High-capacity

- Frame material

- 304 Stainless Steel

- Bowl tilt angle

- Up to 140°

- Agitator type

- Triple Roller Bar, Double/Single Sigma Arm, High Shear

- Enclosed frame design

- Straight grain finish

- Drive system

- Single-end

- Control panel type

- NEMA 12/dust-tight

- Frame type

- Manual or automatic trough hooks

- Trough safety sensors

- Trough in-place safety sensors

- Bowl guard feature

- Dump side stainless steel bowl guard with interlocked hinged doors

- Canopy features

- Anti-drip adapters, interlocked ingredient door, rear sponge door

- Sanitation cover

- For operator panel

- Maintenance/Engineering Convenience Package

- Includes enclosure lighting and grace port with externally mounted utility receptacle

- Bowl refrigeration options

- Direct expansion refrigeration jacket, Cold Bar System, Cold Bar Plus Refrigerated Agitator System