Flow-through cell dissolution testing with Uv analysis

Effortlessly monitor real-time dissolution with flow-through cell technology, ensuring precise UV analysis for pharmaceutical dosage forms, while enhancing testing accuracy and efficiency.

Performs Real-Time UV-Vis Dissolution Analysis

The CE 7smart UV Online by SOTAX is a sophisticated flow-through cell dissolution testing system that integrates real-time UV-Vis analysis. This equipment is pivotal for pharmaceutical and biotech labs focusing on precise API characterization, final dosage forms testing, and quality control. Its unique flow-through cell design supports continuous sampling and immediate analysis, enabling seamless integration into automated processes. This facilitates reproducible testing of a wide range of products, from aspirin tablets to transdermal patches.

Designed for flexibility, the CE 7smart adjusts to media volumes ranging from 50 to 5000 mL without altering hydrodynamic conditions. The apparatus’s ability to shift pH conditions on demand makes it ideal for evaluating biorelevant dissolution profiles, especially for poorly soluble compounds like those in BCS classes II and IV.

Compatible with various UV-Vis spectrometers, it ensures comprehensive traceability and system integrity through robust software control, right administration, and audit trails. The system not only meets stringent GMP and FDA compliance requirements but also offers customizable configurations to tackle the specific needs of R&D, generic drug formulation, and contract research organizations. With easy integration into existing lab setups and user-friendly programming interfaces, the CE 7smart stands out as a reliable solution for advanced dissolution testing.

Benefits

- Enhances precision and reduces analysis time with real-time UV-Vis dissolution testing.

- Ensures rigorous compliance with GMP and FDA standards for pharmaceutical applications.

- Accommodates a wide range of dosage forms, increasing testing flexibility and adaptability.

- Simplifies integration into existing systems with straightforward programming and automation.

- Minimizes operational costs by adapting media volumes without changing hydrodynamic conditions.

- Applications

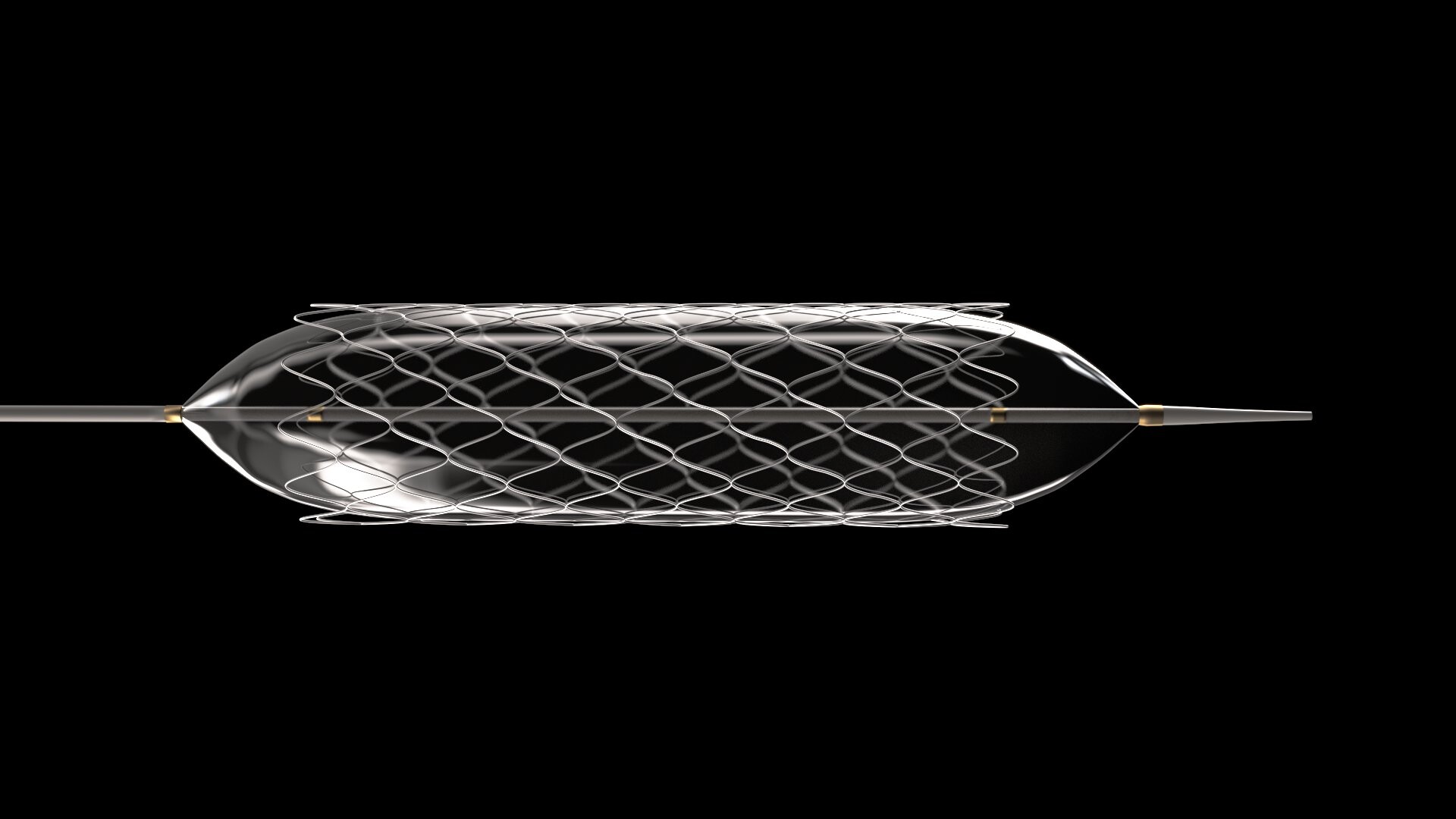

- Medical devices, Gels, Pellets, Granules, Microspheres, Catalysts, Stents, Food, Pharmaceutical tablets, Nano suspensions, Fine chemicals, Coated lenses, Soft-gelatin capsules, Implants, Animal health, Capsules, Transdermal patches, Bottles with screwcaps, Creams, Suppositories, Semi-solids, Apis, Powders, Injectable suspensions

- End products

- Plga microspheres, Antibiotic pellets, Hydrocortisone cream, Liposomal nano suspensions, Glycerin suppositories, Acetone solvents, Platinum catalysts, Hip implants, Aloe vera gel, Omega-3 soft-gel capsules, Paracetamol granules, Vitamin d capsules, Shampoo bottles with screwcaps, Nutritional supplements, Veterinary antibiotics, Nicotine patches, Ibuprofen powder, Anti-scratch coated lenses, Pacemakers, Injectable insulin, Coronary stents, Aspirin tablets

- Steps before

- Pre-formulation, Characterization, QC testing, API preparation, Biorelevant media preparation

- Steps after

- Traceability recording, Data analysis, Compliance checking, Reporting, QC testing

- Input ingredients

- APIs, oral dosage forms, topical dosage forms, parenteral dosage forms, intermediates, pre-formulation samples, poorly soluble compounds, BCS class II compounds, BCS class IV compounds, biorelevant media, pH variant media

- Output ingredients

- dissolution testing results, real-time analysis results, dissolution profiles, traceable reports, method specifications, active pharmaceutical ingredient release rates, IPC testing outcomes, QC testing outcomes

- Market info

- Sotax AG is renowned for its expertise in manufacturing high-quality pharmaceutical testing equipment, including dissolution testing systems, and has a strong reputation for reliability, precision, and innovation in laboratory and industrial applications.

- Automation

- Integrated UV-Vis analysis

- Time Efficiency

- Immediate results for immediate release

- Volume Flexibility

- 50 to 5000 mL

- Test Methods

- USP 1/2/5/6 and USP 4 Flow-through cell

- Adaptability

- Change pH during extended and delayed release testing

- Compliance

- Compendial dissolution instrument

- Method Programming

- Unlimited method programming and reporting

- Traceability

- Complete traceability through audit trail

- Modules

- WinSOTAX®plus

- Working Mechanism

- Flow-through Cell

- Integrated Steps

- Real-time UV-Vis Analysis

- Automation Level

- Programmable Dissolution Profiles

- Traceability

- User Rights Administration, Audit Trail

- Volume Flexibility

- 50 to 5000 mL

- Changeover Time

- Immediate Results

- Method Adaptability

- Biorelevant Media Compatibility

- Batch vs. Continuous Operation

- Reproducible Testing

- Cleaning Method

- Easy Media Changeability

- Automation Level

- PLC-Controlled

- Real-time Analysis

- Immediate Use of Spectrophotometer

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Analyzable Dosage Forms

- Oral, Topical, Parenteral

- Flow-through Cell Type

- Flow-through

- UV Spectrophotometer Type

- Integrated

- Volume Flexibility

- 50 to 5000 mL

- Design

- Compendial

- Cell Setup

- Open and closed system settings

- Control panel type

- WinSOTAX®plus

- Integration possibilities

- Compatible with various UV-Vis brands and types

- Volume flexibility

- 50 to 5000 mL

- System settings

- Open and closed system adaptability