Industrial cooker for sauces and stews

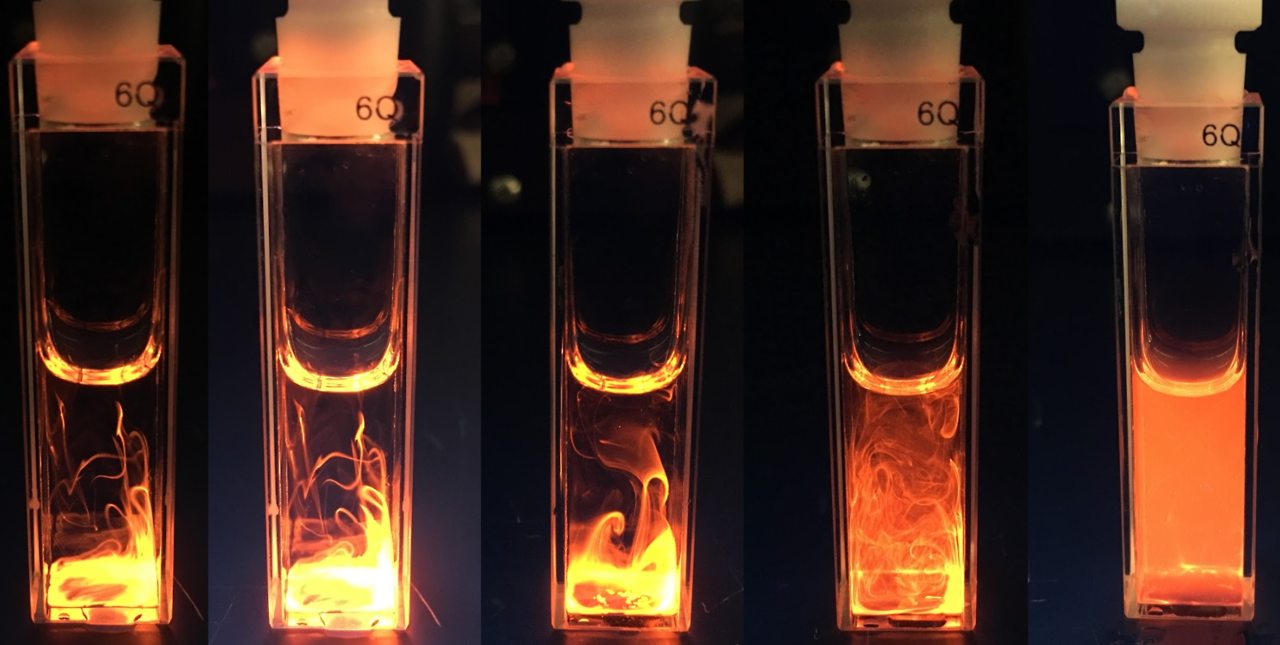

When producing diverse culinary delights such as sauces and stews, achieving even heating with precise temperature control is crucial to maintaining flavor and consistency across large batches.

Processes and Heat Treats Liquid and Slurry Products

The COOK-IT® from ProXES GmbH offers manufacturers a comprehensive solution for processing liquid and slurry products efficiently. Featuring a unique tiltable vessel design with direct steam injection and double jacket heating systems, this cooker system ensures uniform heating and minimizes scorching. With capabilities of up to 3,600 liters per hour, it expertly handles a variety of applications including soups, sauces, and purees. This equipment seamlessly integrates into production lines with PLC control and offers significant energy savings via indirect heating processes. Built with durable materials suitable for food and personal care industries, the COOK-IT® meets stringent hygiene standards and offers optional configurations for specific production needs. Maintenance is streamlined with its integrated Clean-in-Place (CIP) system, ensuring minimal downtime and easy operation.

Benefits

- Enhances product quality with consistent temperature control and minimal scorching.

- Increases processing efficiency with rapid heat transfer technologies.

- Lowers operational costs through significant energy savings in heating processes.

- Reduces maintenance time with an integrated CIP system for easy cleaning.

- Versatile applications, accommodating diverse product needs from food to personal care.

- Applications

- Sauces, Gels, Pesticide, Bakery, Table sauces, Ointment, Vegan, Chocolate, Hummus, Soups, Soft gels, Mascara, Toothpaste, Chemical suspensions, Cream cheese, Sweet spreads, Lotions, Savory spreads, Nail polish, Shower gel, Ceramics, Api suspensions, Pet food, Grease, Fertilizer, Drinks, Mustard, Baby food, Paints, Lacquers, Fillings, Creams, Ketchup, Make-up cream, Stews, Mayonnaise, Dressings, Eye drops, Shampoo, Processed, Lubricants, Lipstick

- End products

- Biscuits, Infant formula, Barbecue sauce, Vitamin soft gels, Hydrocortisone ointment, Dog food kibble, Porcelain ceramics, House paint, Fruit juice, Automotive paint, Bee pollen suspensions, Dijon mustard, Mediterranean hummus, Nitrogen fertilizer, Dark chocolate bars, Soy mayonnaise, Hair styling gel, Cream cheese spread, Lip balm, Hazelnut spread, Herbal shampoo, Alfredo sauce, Tomato soup, Aloe vera cream, Strawberry jam, Guacamole, Herbicide solution, Bath wash, Polymer suspensions, Herbal toothpaste, Artificial tears, Waterproof mascara, Vegan butter, Italian vinaigrette, Engine grease, Nail gloss, Chicken stew, Liquid foundation, Tomato ketchup

- Steps before

- Emulsification, Grinding, Mixing, Homogenizing, Particle size reduction, Deaeration

- Steps after

- Cooling, Pasteurization, Sterilization, Packing

- Input ingredients

- low viscous products, pureed food, fruit puree, sauces with particles, desserts, milk desserts, dairy, fruit, vegetables, potato mash, convenience food, confectionary

- Output ingredients

- stews, soups, sauces, processed cheese, mayonnaise, ketchup, dressings, dips, baby food, desserts, milk desserts, creams, lotions

- Market info

- Proxes is known for manufacturing advanced processing systems for the food, pharmaceutical, and chemical industries, offering expertise in mixing, homogenizing, and size reduction technologies with a strong reputation for engineering tailored equipment solutions.

- Capacity

- Up to 3, 600 l/hour

- Capacity

- Up to 1, 600 l/hour

- Capacity

- Up to 4, 800 l/hour

- Capacity

- Up to 10, 000 kg/hour

- Capacity

- Up to 6, 000 kg/hour

- Heating Temperature

- Up to 95 °C

- Heating Temperature

- Up to 125 °C

- Heating Temperature

- Up to 145 °C

- Cooling Temperature

- Down to 80–85 °C

- Processing Type

- Batch

- Processing Type

- Continuous

- Automation

- CIP/SIP

- Heat Processing

- Direct / Indirect

- Emulsifying

- Yes

- Vacuum Processing

- Yes

- Mixing

- Yes

- Dispersing

- Yes

- Homogenizing

- Yes

- Batch vs. continuous operation

- Batch / Continuous

- Automation level

- PLC / SCADA

- CIP/SIP

- CIP 121°C / SIP 135°C

- Changeover time

- Short changeover time

- Energy efficiency

- Optimized for low consumption

- Cleaning method

- CIP / Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Tank capacity

- Up to 10, 000 kg/hour

- Feed/discharge method

- Tiltable vessel / Direct steam injection

- Control panel type

- Advanced/PLC-controlled

- Heating method

- Direct steam injection / Double jacket heating

- Cooling method

- Indirect cooling / Double jacket

- Container geometry

- Individually adapted

- Control panel type

- Touchscreen / PLC

- Integration possibilities

- SCADA / MES systems

- Adjustable heating methods

- Direct steam / Double jacket heating

- Agitator types

- Scrapers / Propellers

- Modular design

- Expandable / Customizable

- Vacuum processing capability

- Available

- Direct/indirect cooling methods

- Condensing / Double jacket