Homogenizer for high-pressure homogenization

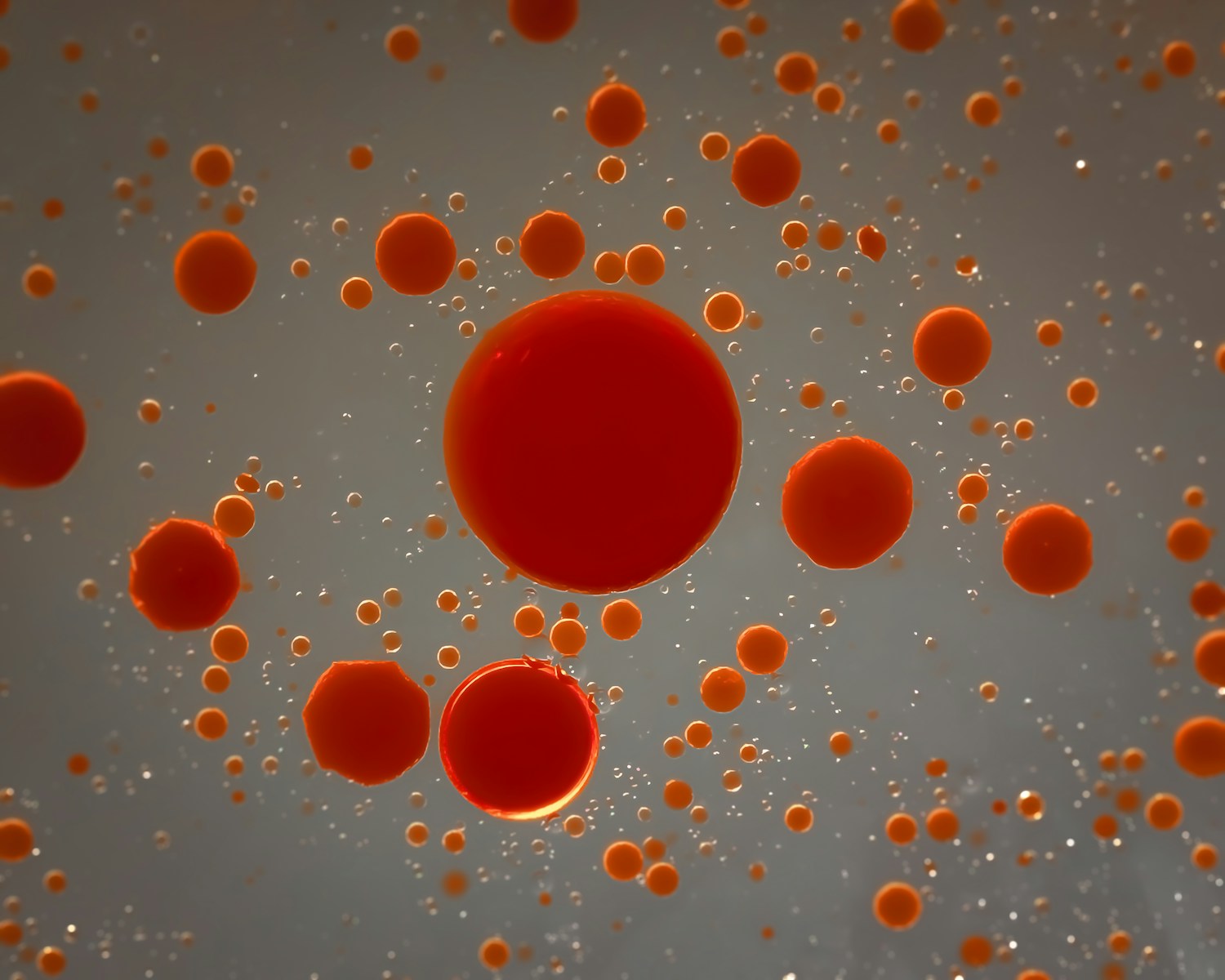

Optimize your production with high-pressure homogenization, essential for achieving uniform emulsions and stable dispersions across diverse applications, enhancing product quality and consistency.

Enhances Emulsification and Product Consistency

The HST range of high-pressure homogenizers, including models like the HLL0 and HL series, offers robust solutions for enhancing liquid product quality across various industries such as food, pharmaceuticals, cosmetics, and chemicals. With a working principle based on subjecting products to intense turbulent and laminar forces, these machines achieve uniform emulsification and improved stabilization in end-products like UHT milk, beauty creams, and fuel emulsions.

Equipped with capacities ranging from 5.5 to 400 kW, these homogenizers can handle throughputs from 300 to 80,000 liters per hour, making them versatile for both small-scale laboratory setups and large-scale production environments. Integration into existing production lines is seamless, thanks to optional PLC control and aseptic design features that enable clean-in-place (CIP) cleaning processes. These units also offer customization in valve materials and piston coatings, enhancing performance and extending service life in demanding operating conditions.

Engineered for energy efficiency, models like the Integrated series reduce water consumption while providing noise insulation. HST homogenizers meet a wide range of regulatory standards, including those necessary for aseptic processing, ensuring compliance with rigorous industry requirements. With a focus on sustainability and operational efficiency, these machines are an essential asset for any facility looking to optimize its homogenization processes.

Benefits

- Enhances product uniformity, significantly improving texture and shelf life.

- Supports aseptic processing, reducing contamination risks and ensuring product safety.

- Reduces operational costs with energy-efficient design and water-saving features.

- Durable materials and customizable components extend equipment lifespan and reliability.

- Seamlessly integrates with existing systems, optimizing production line efficiency.

- Applications

- Drugs, Sauces, Insecticides, Creams, Nutraceuticals, Herbicides, Cosmetics, Colors, Chemical emulsions, Dressings, Resins, Juice, Latex, Dairy products

- End products

- Cream, Egg-based products, Uht milk, Mixed ice cream, Agricultural insecticides, Resin dispersions, Fruit juices, Color pigments, Intravenous lipid emulsions, Salad dressings, Liposome formulations, Condensed milk, Pharmaceutical ointments, Fresh milk, Ketchup, Pigment dispersion, Baby formula, Latex products, Lubricant blends, Cosmetic beauty creams, Yoghurt, Wax emulsions, Fuel/water emulsions

- Steps before

- High Temperature Processing, Heat Treatment, Product Pressurization

- Steps after

- Packing, Cooling, Storage, Labelling

- Input ingredients

- milk, cream, vegetable juices, UHT milk, yoghurt, baby and infant food, condensed milk, ketchup, sauces, dressings, mixed ice cream, fruit juices, egg products, special drinks, intravenous emulsions, liposomes, ingredients, textures, beauty creams, dyes, ointments, cell disruption substances, pigment dispersions, lubricants, fuels/water emulsions, wax emulsions, insecticides, herbicides, resin dispersions, nanosomes, colours, latex

- Output ingredients

- stable emulsions, consistent mixtures, uniform dispersions, small fat globules, agglomerate-free products, enhanced colour intensity, improved flavour, better consistency, extended shelf life

- Market info

- HST Maschinenbau is known for its expertise in designing and manufacturing custom-engineered industrial machinery, particularly in the sectors of hydraulics and automation, with a strong reputation for quality and innovative solutions tailored to client needs.

- Capacity range

- 5.5 - 250 kW (300 to 35, 000 l/h)

- Capacity range

- 55-90 kW (8, 000 to 14, 000 l/h) and 400 kW (up to 80, 000 l/h)

- Capacity range

- 3-75 kW (10, 000 l/h at 200 bar)

- Noise insulation

- Noise insulation cladding

- Design option

- Aseptic design

- Design option

- ATEX design

- Valve types

- PLUG, PILOTED, Multigap

- Valve control

- Pneumatic or hydraulic

- Piston material

- Standard, chrome-plated, ceramic, special HST coating

- Energy consumption

- Reduced water consumption feature

- Working mechanism

- High-pressure homogenization

- Flow type

- Continuous

- Automation level

- Pneumatic or hydraulic valve control

- Design options

- Aseptic, ATEX

- Energy efficiency

- Energy-saving Multigap valves

- Maintenance

- Easy to service valves

- Noise level

- Reduced with noise insulation cladding

- Pressure range

- Up to 200 bar

- Capacity range

- 5.5 kW to 400 kW

- Heat treatment compatibility

- Post UHT processing

- Piston options

- Standard, chrome-plated, ceramic, HST coating

- Abrasion resistance

- High

- Biological compatibility

- Suitable for UHT and sterile products

- Cleanability

- Aseptic design available

- Corrosive resistance (e.g. acids)

- High-strength stainless steels

- Density/particle size

- Adaptable via homogenizing valves

- Feed/discharge method

- Turbulent and laminar forces

- Narrow gap

- Ring-shaped

- Capacity

- 5.5 - 250 kW (300 l/h until 35, 000 l/h)

- Noise insulation

- Cladding

- Aseptic design

- Optional

- ATEX design

- Optional

- Piston material

- Standard, chrome-plated, ceramic, special HST coating

- Valve material

- High-strength stainless steels, sintered materials, ceramics

- Aseptic design

- Available

- ATEX design

- Available

- Noise insulation cladding

- Available

- Piston material

- Chrome-plated, Ceramic, HST coated

- Valve material

- High-strength stainless steel, sintered, ceramic

- Homogenizing valve types

- PLUG, PILOTED, Multigap

- Control method

- Pneumatic, Hydraulic

- Packing system

- Custom materials for extended service life