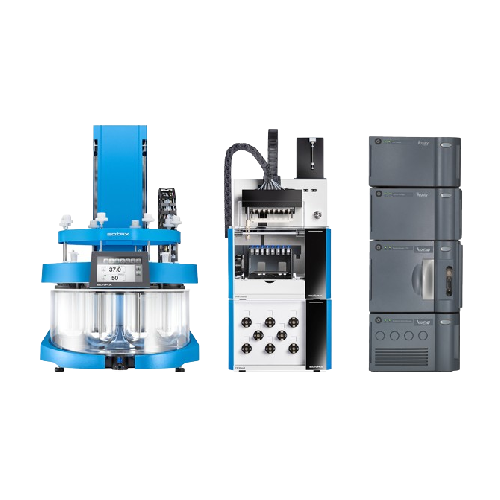

Automated dissolution testing with direct Hplc injection

Streamline your lab operations with precise and efficient direct sample injection into HPLC systems, eliminating manual transfer errors and reducing processing time, ensuring high-quality analytical results for complex pharmaceutical formulations.

Automates Sample Injection into HPLC/UPLC Systems

The ATS Xtend™ LC On-/Offline dissolution tester from SOTAX seamlessly integrates into pharmaceutical and biotech production lines, automating the injection of dissolution samples directly into HPLC/UPLC systems. Its unique ability to simultaneously sample, filter, and inject ensures minimal degradation and high throughput by treating samples with precision down to 0.2-micron filtration. Ideal for a wide range of applications, from aspirin tablets to insulin injectable suspensions, it meets stringent industry requirements while maintaining sample integrity through optional cooling. With flexible integration across various chromatography systems, it supports parallel processing to expedite testing cycles. The system is designed for ease of maintenance, featuring automated cleaning routines to prevent cross-contamination and ensure consistent operation.

Benefits

- Increases operational efficiency by automating sample injection and minimizing manual handling.

- Maintains high sample integrity with integrated filtration and temperature control, preventing degradation.

- Enhances productivity with parallel processing capabilities, reducing lead time for analytical results.

- Supports compliance with industry standards through precise and repeatable sampling processes.

- Facilitates seamless system integration, allowing flexibility with various HPLC/UPLC brands and configurations.

- Applications

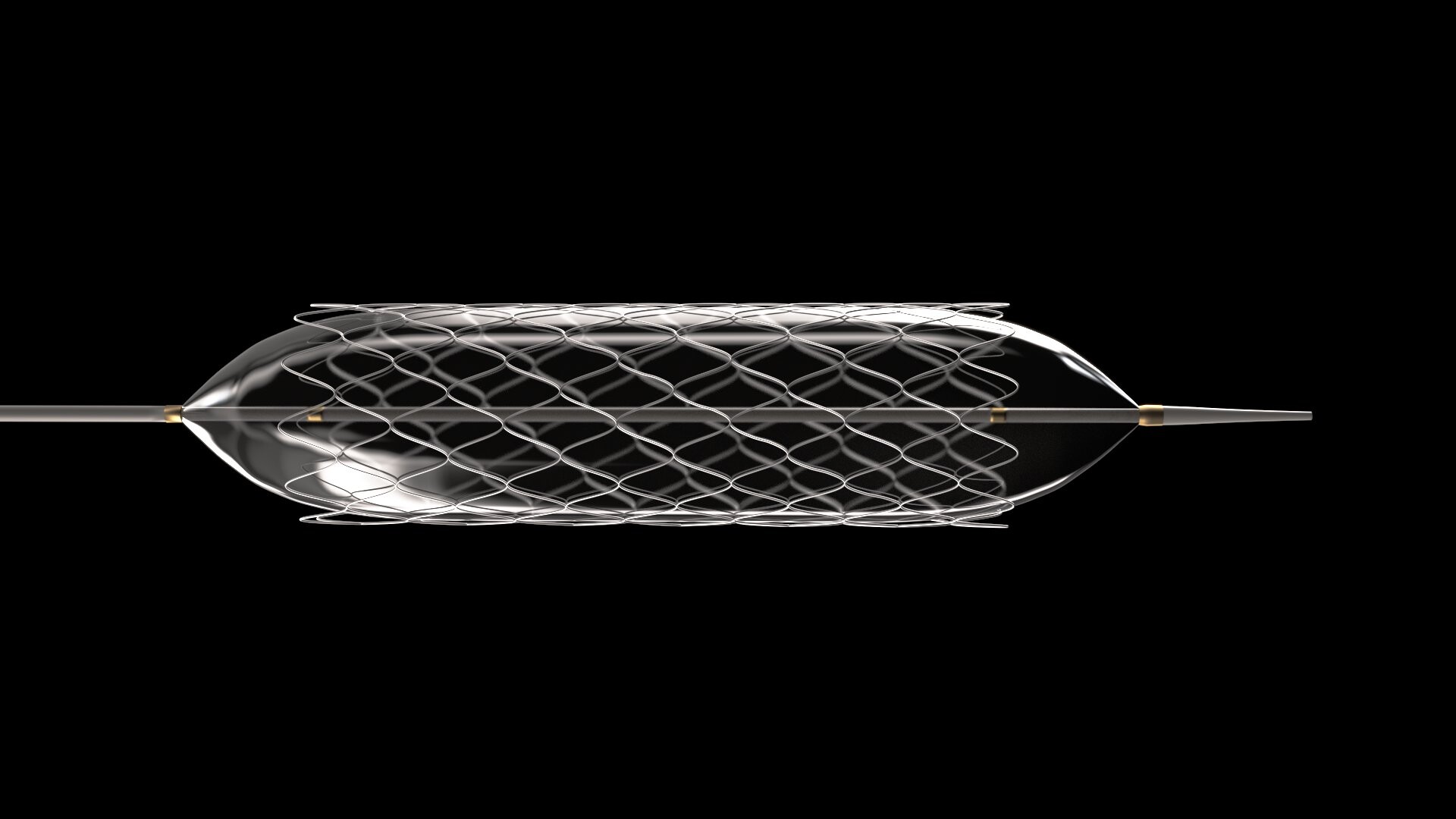

- Medical devices, Gels, Pellets, Granules, Microspheres, Catalysts, Stents, Food, Pharmaceutical tablets, Nano suspensions, Fine chemicals, Soft-gelatin capsules, Implants, Animal health, Capsules, Washtabs, Transdermal patches, Creams, Suppositories, Semi-solids, Apis, Powders, Injectable suspensions

- End products

- Probiotics for animal health, Ibuprofen active pharmaceutical ingredient (api), Orthopedic implants, Hydrocortisone cream, Insulin injectable suspensions, Liposomal nano suspensions, Zeolite fine chemicals, Glycerin suppositories, Platinum catalysts, Omega-3 soft-gelatin capsules, Talc powder, Protein capsules, Dishwasher wash tabs, Effervescent granules, Paclitaxel-eluting microspheres, Coated pellets, Encapsulated vitamins for food supplements, Benzoyl peroxide gel, Heart stents, Aspirin tablets, Lidocaine transdermal patches

- Steps before

- Media Preparation, Degassing, Heating

- Steps after

- Cooling, HPLC/UPLC Analysis, Cleaning

- Input ingredients

- dissolution samples, media, HPLC / UPLC columns, filtered samples

- Output ingredients

- analyzed samples, chromatography results, protocolled temperatures, dissolution process documentation

- Market info

- Sotax AG is renowned for its expertise in manufacturing high-quality pharmaceutical testing equipment, including dissolution testing systems, and has a strong reputation for reliability, precision, and innovation in laboratory and industrial applications.

- Automation

- Automated injection

- Filtration

- 0.2 microns

- Integration

- Flexible integration with HPLC/UPLC

- Cooling option

- Optional powerful cooling

- Sampling method

- Automated sample collection

- Cleaning method

- Automated cleaning routine

- Monitoring

- Advanced video monitoring

- Pumping method

- CP piston pump

- Data Management

- WinSOTAX®plus software

- Automation level

- Automated

- Batch vs. continuous operation

- Batch

- CIP/SIP

- Manual / Automated cleaning routines

- Changeover time

- Minimal due to automated processes

- Integration capability

- Flexible integration with HPLC/UPLC systems

- Sample management

- Automated sample collection and injection

- Filtration capability

- 0.2 microns

- Error prevention

- Automated processes to minimize errors

- Cooling option

- Powerful cooling for sample preservation

- Cleaning method

- Automated with EasyTouch™ interface

- Carry-over prevention

- Special cleaning routine for injection loop

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Configuration

- On-/Offline

- Control panel type

- EasyTouch™ user interface

- Feeding method

- Automated sampling

- Filtration porosity

- 0.2 microns

- Filter type

- Tip filters, cannula filters, disc filters, syringe filters

- Discharge method

- Direct injection into HPLC/UPLC

- Integration possibilities

- HPLC / UPLC systems

- Filtration customization

- 0.2 microns filters, disc filters, syringe filters

- Control panel type

- EasyTouch™ user interface

- Cooling options

- Optional powerful cooling

- Injection automation

- SAM SR sample manager

- Parallel processing

- Simultaneous injection and sample collection

- Cleaning routine customization

- Special cleaning routine for injection loop

- Monitoring options

- CenterView™ video monitoring, AutoLift™ temperature monitoring

- Automation level

- Fully automated sampling, filtration, and injection