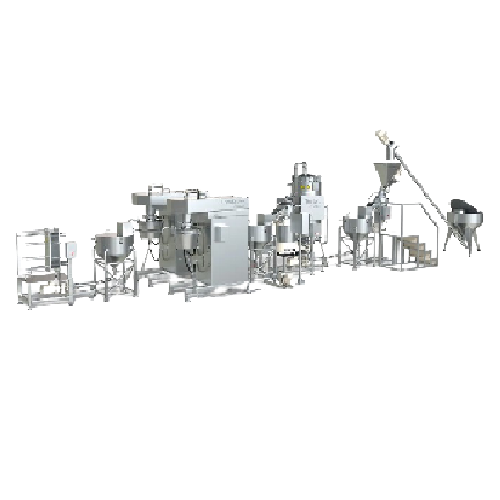

Continuous tahina production line

Streamline your tahina production with precise grinding and controlled cooling, ensuring consistent quality and flavor in every batch while reducing processing times.

Integrates Cooking, Mixing, and Cooling

The Conti Preparation Lines from ProXES comprise a comprehensive system designed to enhance continuous food processing efficiency. Specializing in integrating cooking, mixing, and cooling, these lines address the challenge of maintaining product consistency across various food applications. Capable of processing up to 4,000 kg per hour, the system supports products like creamy hummus, sauces, and soups. Equipped with a PLC-controlled environment for seamless operation, the lines facilitate automation and offer remote monitoring capabilities. Energy consumption is optimized with efficient heating modules, reducing overall operational costs. Constructed from durable stainless steel, the equipment ensures resistance to corrosive food ingredients and meets stringent food safety standards. With built-in CIP systems, these lines offer efficient cleaning cycles, minimizing downtime. ProXES provides extensive customization options, including support for adjusting configurations based on specific production needs.

Benefits

- Enhances production consistency across diverse food applications, improving product quality.

- Increases operational efficiency with high-speed processing capabilities up to 4,000 kg per hour.

- Reduces operational costs with energy-efficient heating and cooling modules.

- Minimizes downtime due to integrated CIP systems, ensuring quick and effective cleaning.

- Adapts to specific production needs with customizable configurations and engineering support.

- Applications

- Sauces, Gels, Table sauces, Processed cheese, Pesticides, Ointment, Chocolate, Bakery products, Hummus, Soups, Soft gels, Mascara, Toothpaste, Chemical suspensions, Cream cheese, Sweet spreads, Lotions, Savory spreads, Nail polish, Shower gel, Ceramics, Api suspensions, Pet food, Grease, Drinks, Mustard, Baby food, Paints, Lacquers, Fillings, Creams, Fertilizers, Ketchup, Vegan food, Make-up cream, Stews, Mayonnaise, Dressings, Eye drops, Shampoo, Lubricants, Lipstick

- End products

- Quick-dry nail polish, Filled chocolates, Béchamel sauce, Beef stew, Jam, Paint suspensions, Wood lacquer, Classic hummus, Hydrating lotion, Anti-dandruff shampoo, Paracetamol suspension, Personal lubricant gel, Fish oil soft gels, Automotive paint, Volumizing mascara, Dijon mustard, Caesar dressing, Canned pet food, Nitrogen fertilizer, Fluoride toothpaste, Moisturizing shower gel, Soy sauce, Energy drinks, Matte lipstick, Antiseptic ointment, Pottery clay, Cream cheese spread, Motor oil, Saline eye drops, Tomato soup, Aioli, Moisturizing cream, Fruit purees, Insecticide spray, Baba ghanoush, Fruit filling, Sliced processed cheese, Brioche dough, Graphite lubricant, Tofu, Foundation cream, Tomato ketchup

- Steps before

- Ingredient dosing, Fat melting, Starch dissolving, Feeding, Pre-cutting, Soaking

- Steps after

- Cooling, Vacuum cooling, Packing, Evaporation, Final cutting, Sieving, De-aeration

- Input ingredients

- fat, starch, ingredients, cheese, chili, hummus, mustard seeds, nuts, vegetables, sesame seeds

- Output ingredients

- caramel, processed cheese, chili sauce, hummus, mustard, nut paste, vegetable purée, tahina

- Market info

- Proxes is known for manufacturing advanced processing systems for the food, pharmaceutical, and chemical industries, offering expertise in mixing, homogenizing, and size reduction technologies with a strong reputation for engineering tailored equipment solutions.

- Capacity

- 2, 000 - 4, 000 kg/h

- Heating Temperature

- Up to 145°C

- Flash Cooling Temperature

- 80–85°C

- Vacuum Deaeration

- Available

- Automation

- Continuous Preparation

- Cooling Method

- Vacuum Cooling

- Pre-cutting

- Available

- Ingredient Dosing

- Automatic

- Fat Melting

- Available

- Cooking Method

- Direct Steam Injection (DSI)

- Batch vs. continuous operation

- Batch / Inline Continuous

- Automation level

- Manual / PLC / SCADA

- CIP/SIP

- CIP 121°C / SIP 135°C

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Integrated process steps

- Cutting, Mixing, Heating, Cooling

- Working mechanism

- Vacuum, Pressurized Cooking

- Cleaning method

- CIP / Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Varies based on configuration

- Tank shape

- Varies

- Tank size

- Varies based on capacity

- Feed method

- Automatic feeding

- Discharge method

- Continuous or batch discharge

- Control panel type

- PLC-controlled interface

- Compact footprint

- Optimized for space efficiency

- Customization options

- Modular system components

- Control panel type

- HMI / Touchscreen

- Integration possibilities

- SCADA / PLC

- Modular configuration

- ProXES modular kit system

- Process customization

- Machine, process, recipe, formulation

- Capacity customization

- Custom capacities on request