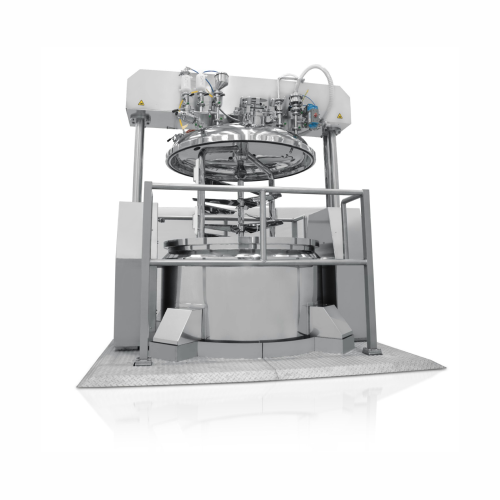

Vacuum turboemulsifiers for liquid and creamy products

Simplify your production workflow with high-capacity vacuum turboemulsifiers, perfect for achieving precise emulsification and optimal mixing of liquid and creamy formulations in large-scale operations.

Emulsifies, Mixes, Heats, and Cools Liquid Formulations

The TURBO-MEK 1500 – 6000 Series from the Marchesini Group is a line of vacuum turboemulsifiers engineered to meet the demanding needs of cosmetic and personal care product manufacturers. These emulsifiers excel in processing liquid and creamy formulations, thanks to their robust construction and advanced mixing capabilities. Equipped with a variable-speed turbine located at the vessel’s base, they ensure precise emulsification and consistent product texture. Ideal for producing moisturizing lotions, facial creams, and shampoos, these emulsifiers support batch and high-speed operations with capacities ranging from 1500 to 6000 liters. Integration into your production line is seamless, facilitated by the inclusion of CIP and SIP systems for efficient cleaning and sterilization. The vessel, constructed from AISI 304 stainless steel with optional Atex certification, offers excellent material integrity and corrosion resistance. Energy efficiency is enhanced by optional pressure vessel emptying and heating via electric or steam systems. For custom processing requirements, ancillary melters and double-planetary blade mixers are available, ensuring adaptability across various formulation needs. The series also includes a D-connect feature for remote service, cementing its role as a versatile and reliable processing solution.

Benefits

- Enhances product consistency with precise emulsification and mixing.

- Integrates easily with existing systems using CIP and SIP for efficient cleaning.

- Reduces energy usage with optimized electric or steam heating systems.

- Supports diverse formulation needs with customizable mixing configurations.

- Facilitates large-scale production with capacities up to 6000 liters.

- Applications

- Personal care products, Liquid formulations, Creamy products, Cosmetics

- End products

- Mascara formulations, Eye creams, Sunscreen lotions, Hair conditioners, Facial creams, Foundation makeup, Shampoo, Body wash, Hair gel, Liquid soap, Moisturizing lotions, Liquid foundation

- Steps before

- Preparation, Ingredient Loading

- Steps after

- Packing, Labelling, Over-Wrapping, Casepacking, Palletising

- Input ingredients

- liquid products, creamy products, raw materials for emulsification

- Output ingredients

- emulsified liquids, emulsified creams, finished cosmetic products

- Market info

- Marchesini (Dumek) is renowned for designing and manufacturing advanced engineered-to-order equipment for the pharmaceutical and cosmetics industries, focusing on innovation, quality, and customization to meet specific client needs efficiently.

- Capacity

- 1500 - 6000 litres

- Vessel heating system

- Electric or steam

- Material

- AISI 304 stainless steel

- Touchscreen size

- 12 inches

- Automation

- Touchscreen-controlled

- Turbine position and speed control

- Positioned on the vessel bottom, regulated by inverter

- Slow mixer movement and speed control

- Counter-rotating, regulated by inverter

- Insulating jacket

- Vessel insulating jacket

- CIP and SIP systems

- Available

- Vacuum circuit

- Available

- Remote service connection

- D-connect

- ATEX certification

- Full, optional

- Lifting lid

- Available

- Tilting vessel

- Optional, up to 3000 litres

- Working mechanism

- Vacuum turboemulsifier

- Integrated steps

- Heating, cooling, mixing

- Batch vs. continuous operation

- Batch

- CIP/SIP

- CIP and SIP systems

- Automation level

- 12” Touchscreen, PLC control

- Cleaning method

- CIP / inside vessel washing

- Energy efficiency

- Electric or steam heating

- Changeover time

- Optional features for quick access

- Automation level

- Remote service with App (D-connect option)

- Corrosive resistance (e.g. acids)

- AISI 304 stainless steel

- Lid type

- Lifting lid

- Tank size

- 1500 - 6000 litres

- Base material

- AISI 304 stainless steel

- Jacket type

- Heating and cooling

- Optional features

- Tilting vessel, Ancillary melters

- Discharge method

- Vessel emptying by pressure (option)

- Control panel type

- 12” Touchscreen

- Construction material

- Stainless steel

- Cooling system

- Vessel equipped with jacket

- Certification availability

- Full Atex certification (option)

- Control panel type

- 12” Touchscreen

- Integration possibilities

- D-connect for connection and remote service with dedicated App (option)