High-pressure homogenizers for liquid products

Achieve consistent emulsions and stable dispersions with high-pressure homogenizers that enhance product texture and extend shelf life, ensuring your formulations meet exacting quality standards.

Homogenizes and Stabilizes Liquid Products

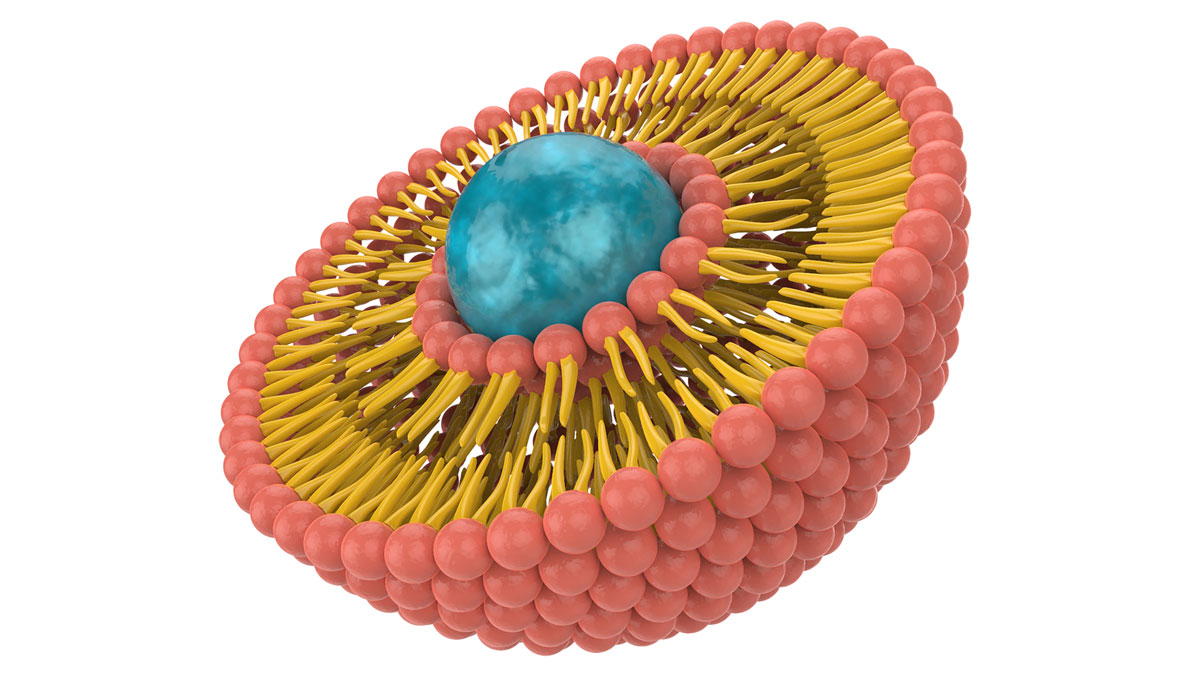

The HST line of high-pressure homogenizers offers comprehensive homogenization solutions designed for diverse industries including food, pharmaceuticals, cosmetics, and chemicals. Known for their robust design, these machines feature a ring-shaped gap where pressurized products undergo turbulent and laminar forces, effectively breaking down and distributing fat globules and agglomerates. This physical process significantly enhances the stability, texture, and flavor of end products such as condensed milk, baby formula, and intravenous emulsions.

Each model, from the compact HLL0 to the high-capacity HLI8, offers various throughput options, with capacities ranging from 300 to 80,000 liters per hour. These homogenizers can be integrated seamlessly into existing production lines, offering options for aseptic processes and ATEX compliance. They feature noise insulation cladding to minimize operational sound, and a reduction in water consumption in the “Integrated” series to enhance energy efficiency.

The machines utilize high-strength materials such as stainless steel, ceramics, and specially coated pistons, ensuring durability and resistance to wear. Supported by a CIP system, maintenance is effective and contamination-free, while the customizable designs and engineering support allow for tailored solutions to specific production needs. Meeting industry standards, HST homogenizers provide reliable, efficient, and scalable solutions to enhance operational efficiencies across a spectrum of liquid processing applications.

Benefits

- Enhances product quality by ensuring uniform particle distribution and improved stability.

- Supports environmental compliance with reduced water and energy consumption.

- Decreases operational noise levels, enhancing workplace conditions.

- Extends equipment lifespan with durable materials and special coatings.

- Facilitates seamless integration into existing production lines, reducing setup time.

- Applications

- Sauces, Cosmetics, Ointments, Food, Chemicals, Colours, Dyes, Insecticides, Textures, Beauty creams, Juices, Liposomes, Resin dispersions, Latex, Nanosomes, Creams, Pharmaceuticals, Intravenous emulsions, Dressings, Emulsions, Herbicides, Dispersions, Dairy products

- End products

- Automotive waxes, Fruit smoothies, Latex gloves, Biocide sprays, Baby formula, Infusion solutions, Nanoscale colorants, Egg-based sauces, Water-resistant coatings, Aseptic milk, Condensed milk, Yogurt drinks, Topical ointments, Anti-aging creams, Pigment inks

- Steps before

- Grinding, Mixing, Emulsification, UHT Treatment

- Steps after

- Sterilization, Packing, Filling, Cooling

- Input ingredients

- fresh milk, cream, vegetable juices, UHT milk, yoghurt, baby and infant food, condensed milk, ketchup, sauces and dressings, mixed ice cream, fruit juices, egg products, special drinks, intravenous emulsions, liposomes, ingredients, textures, beauty creams, dyes, ointments, cell disruption, pigment dispersions, lubricants, fuels/water emulsions, wax emulsions, insecticides/herbicides, resin dispersions, nanosomes, colours, latex

- Output ingredients

- stability, colour intensity, flavour, consistency, long shelf life, creaming stability

- Market info

- HST Maschinenbau is known for its expertise in designing and manufacturing custom-engineered industrial machinery, particularly in the sectors of hydraulics and automation, with a strong reputation for quality and innovative solutions tailored to client needs.

- Capacity Range

- 5, 5 - 250kW (300l/h until 35, 000l/h)

- Capacity Range

- 55-90kW (8, 000 - 14, 000l/h) and 400kW (up to 80, 000l/h)

- Capacity Range

- 3-75kW (10, 000l/h – 200bar)

- Design Options

- Aseptic design, ATEX design

- Noise Insulation

- Noise insulation cladding available

- Valve Type

- PLUG, PILOTED, Multigap

- Piston Material

- Standard, chrome-plated, ceramic, HST special coating

- Pressure Control

- Pneumatically or hydraulically controlled

- Working mechanism

- High-pressure homogenization

- Flow type

- Laminar and turbulent forces

- Fat globule distribution

- Even distribution

- Product stability

- Enhances stability and shelf life

- Automation level

- Pneumatic or hydraulic control

- Batch vs. continuous operation

- Inline Continuous

- Aseptic capabilities

- Available as an option

- Noise insulation

- Insulation cladding available

- Pressure range

- 200 bar

- Energy efficiency

- Energy-saving Multigap valve

- Cleaning method

- CIP Compatible

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Pressure handling

- High-pressure

- Wide application

- Food, pharmaceutical, cosmetics, chemicals