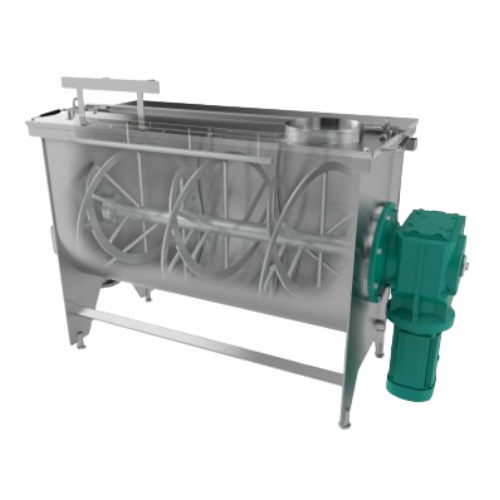

Ribbon blender for homogeneous blending of solids

Achieve perfectly consistent blends with a ribbon blender that ensures rapid and gentle mixing of dry or dry/wet products, eliminating dead spaces and preserving ingredient integrity in every batch.

Blends Granules, Powders, and Solid Ingredients

The Ribbon Blender series from Gpi De Gouwe offers precise and consistent mixing solutions for diverse applications, including food, chocolate, and cosmetic industries. Each model, from the RB100 to RB2000, features dual ribbons that ensure homogeneous blending without product damage. This equipment enables efficient processing of powders, granules, rice, sugars, and spices, achieving mixing times between 2 to 15 minutes per batch with no dead spaces. Available in stainless steel materials (SS304 and SS316L), it accommodates various operational needs with options for heating, cooling, and integration of control panels. Designed for batch operations, these blenders are equipped with features like manual or automated valves, load cells, and CIP cleaning systems, ensuring seamless integration into your production line. Compliance with industry standards and customization options ensure alignment with specific production requirements, making these blenders a versatile addition to any processing department.

Benefits

- Ensures consistent product quality with even blending and no dead spaces.

- Minimizes processing time, achieving homogeneous mixes in as little as 2 minutes.

- Enhances operational efficiency with customizable features like integrated control panels.

- Supports versatile production needs with options for heating, cooling, and various material finishes.

- Facilitates easy maintenance and compliance with CIP cleaning systems and durable stainless steel construction.

- Applications

- Food, Soups, Sauces, Granules, Sugars, Cosmetics, Lotions, Flour, Spices, Rice, Powders, Chocolate, Creams, Fruit

- End products

- Chocolate truffles, Breakfast cereal granola, Facial creams, Confectionery coatings, Fruit preserves, All-purpose flour mix, Jasmine rice blend, Curry spice blend, Pharmaceutical powders, Caster sugar mix, Body lotions

- Steps before

- Grinding, Emulsification, Drying

- Steps after

- Packing, Coating

- Input ingredients

- granules, powders, rice, sugars, spices, flour

- Output ingredients

- homogeneous mixture of solids

- Market info

- GPI De Gouwe is known for manufacturing bespoke stainless steel tanks and processing equipment, specializing in the food, chemical, and pharmaceutical industries, with a reputation for delivering high-quality, custom-engineered solutions.

- Capacity

- 100–2000 L

- Batch mixing time

- 2–15 minutes

- Material Options

- SS304, SS316L

- Operation type

- Batch

- Automation

- Integrated control panel

- Heating and cooling option

- Available

- Cleaning method

- CIP

- Valve type

- Manual or automated

- Dead space

- Free from dead spaces

- Loadcells

- Available

- Batch vs. continuous operation

- Batch

- Mixing time

- 2 - 15 minutes per batch

- Dead space

- Completely dead space free

- Product damage prevention

- Specially designed ribbon

- Automation level

- Manual / PLC

- Cleaning method

- CIP

- Corrosive resistance (e.g. acids)

- SS304, SS316L

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product type

- Granules / Powders / Rice / Sugars / Spices / Flour

- FDA materials

- SS304, SS316L

- Machine Footprint

- Varies with model

- Tank Size

- 100 to 2000 liters

- Feed/Discharge Method

- Inner and outer ribbon

- Control Panel Type

- Integrated control panel

- Compact Footprint

- Customizable

- Material type

- SS304, SS316L

- Heating option

- Heated

- Cooling option

- Cooled

- Control panel type

- Integrated control panel

- Valve options

- Manual or automated valves

- Cleaning option

- CIP cleaning

- Lid type

- Lid equipped with removable grate

- Seals

- Various seals

- Surface finishes

- Various surface finishes